The need for speed is hard wired into humans, it seems. Even those of us who enjoy flying slow also love the idea of eating up the miles in some fast cruiser. A flight that turns a three-hour driving ordeal into a 25-minute aerial jaunt becomes a bragging right for any pilot.

Other than the pure thrill of logging a high groundspeed, going fast is only useful when you’re going somewhere. If perhaps your goal is aerial sightseeing then slow (and probably low) is the way to go. If you have to go fast, remember that old saying from auto racing: “Speed cost money; how fast do you want to go?” This equally applies to aviation.

FAA actually drew a speed line back in the early 2000s when the SP/LSA rule was being written (just as now with the LSA 2023 rule in the works). No, I don’t refer to the 120-knot speed limit we’ll discuss below.

The need for speed is hard wired into humans, it seems. Even those of us who enjoy flying slow also love the idea of eating up the miles in some fast cruiser. A flight that turns a three-hour driving ordeal into a 25-minute aerial jaunt becomes a bragging right for any pilot.

Other than the pure thrill of logging a high groundspeed, going fast is only useful when you’re going somewhere. If perhaps your goal is aerial sightseeing then slow (and probably low) is the way to go. If you have to go fast, remember that old saying from auto racing: “Speed cost money; how fast do you want to go?” This equally applies to aviation.

FAA actually drew a speed line back in the early 2000s when the SP/LSA rule was being written (just as now with the LSA 2023 rule in the works). No, I don’t refer to the 120-knot speed limit we’ll discuss below.Go-Fast Mania Spreads to USA — BRM Aero’s Bristell “Speedster” with 915iS Fixed Pitch Prop

The need for speed is hard wired into humans, it seems. Even those of us who enjoy flying slow also love the idea of eating up the miles in some fast cruiser. A flight that turns a three-hour driving ordeal into a 25-minute aerial jaunt becomes a bragging right for any pilot.

FAA actually drew a speed line back in the early 2000s when the SP/LSA rule was being written (just as now with the LSA 2023 rule in the works). No, I don’t refer to the 120-knot speed limit we’ll discuss below. I refer to a slower speed, the one implied in the minimum 20 hours required for a Sport Pilot certificate.

Then LSA got glass cockpits, leather interiors, high performance engines, autopilots, and more. Prices went up accordingly and today we have a bifurcated market — just like FAA once envisioned, with simpler sub-87 knot airplanes and faster but more costly models.

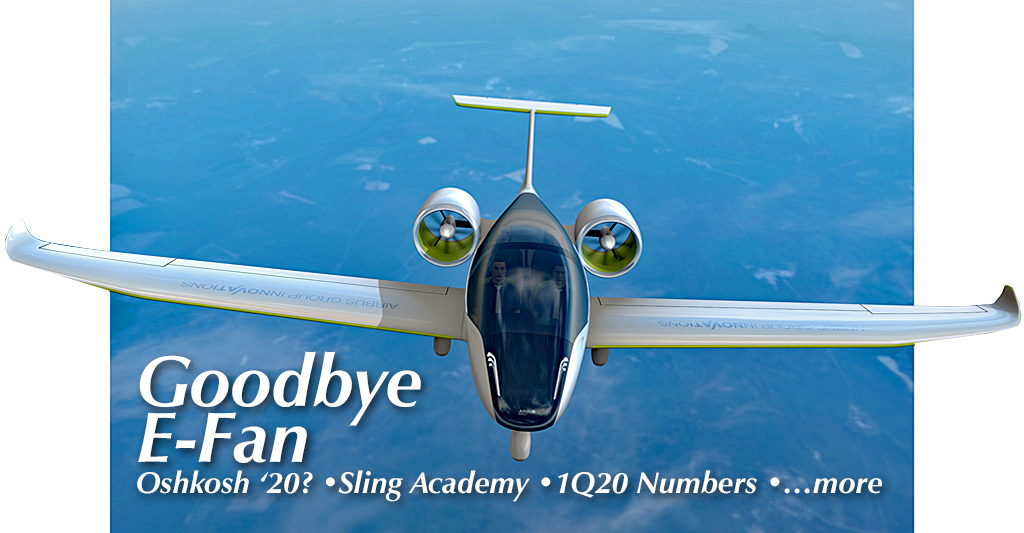

The aircraft I’ve written about recently — Blackwing 600RG, JMB VL3, Porto Risen — join other models from capable builders. Most of these are presently built in Europe as local regulations allow faster speeds and the hardware that goes with it. One example is Bristell from BRM Aero.

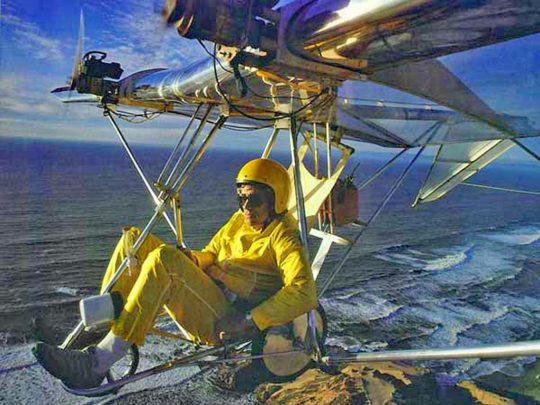

In late March 2020, before coronavirus had completely invaded our lives, I went aloft to photograph Bristell’s Speedster powered by the Rotax 915iS that is becoming the engine of choice for developers of the fastest LSA-like airplanes.

Imported by Bristell Aircraft operated by longtime aviation businessman, Lou Mancuso, whom many student pilots know as “The Landing Doctor” (website). He is quite the knowledgeable pilot. When some said, “Hey, a LSA can’t fly faster than 120 knots,” Lou has a reasoned reply, as he usually does.

“By the way,” Lou continued, “the Bristell 915iS Speedster is an LSA as it has fixed gear, a ground adjustable prop, and weighs only 852 pounds, well within the LSA max empty weight limit of 900 pounds.”

Some people noted the IFR-capable avionics in the Bristell 915 panel and Lou replied, “It can also be flown IFR in IMC if equipped with some certified avionics and [is converted to] an ELSA.” He cautioned, “It does not have static wicks so to stay safe it needs to be light IMC.”

Lou Mancuso shoots the photographer after the low-and-tight formation flying ended.

Looking ahead toward LSA 2023, Lou commented, “In a couple of years we should be able to use a constant speed prop and gain additional performance.”

On the day we shot photos and video of the Bristell Speedster, Lou said this particular aircraft has achieved 170 miles per hour flight true airspeed at 12,500 feet using a Duc 4-blade ground adjustable prop.

Enjoy this short (3:17) video and see Bristell on the ground and in-flight near DeLand, Florida. (Landing fields were nearby but just out of sight during the shoot. A safety briefing preceded the flight.)

The need for speed is hard wired into humans, it seems. Even those of us who enjoy flying slow also love the idea of eating up the miles in some fast cruiser. A flight that turns a three-hour driving ordeal into a 25-minute aerial jaunt becomes a bragging right for any pilot.

Other than the pure thrill of logging a high groundspeed, going fast is only useful when you’re going somewhere. If perhaps your goal is aerial sightseeing then slow (and probably low) is the way to go. If you have to go fast, remember that old saying from auto racing: “Speed cost money; how fast do you want to go?” This equally applies to aviation.

FAA actually drew a speed line back in the early 2000s when the SP/LSA rule was being written (just as now with the LSA 2023 rule in the works). No, I don’t refer to the 120-knot speed limit we’ll discuss below.

The need for speed is hard wired into humans, it seems. Even those of us who enjoy flying slow also love the idea of eating up the miles in some fast cruiser. A flight that turns a three-hour driving ordeal into a 25-minute aerial jaunt becomes a bragging right for any pilot.

Other than the pure thrill of logging a high groundspeed, going fast is only useful when you’re going somewhere. If perhaps your goal is aerial sightseeing then slow (and probably low) is the way to go. If you have to go fast, remember that old saying from auto racing: “Speed cost money; how fast do you want to go?” This equally applies to aviation.

FAA actually drew a speed line back in the early 2000s when the SP/LSA rule was being written (just as now with the LSA 2023 rule in the works). No, I don’t refer to the 120-knot speed limit we’ll discuss below.

Our most-read story of 2020 was this

Our most-read story of 2020 was this  “A few weeks earlier,” he continued, “we started high-speed taxi tests. We noticed immediately that this aircraft is something special. The turbo-charged engine (

“A few weeks earlier,” he continued, “we started high-speed taxi tests. We noticed immediately that this aircraft is something special. The turbo-charged engine ( “On Tuesday the weather conditions were perfect. We decided to fly at 10,000 feet. The [FAI] criteria that the course could only be flown once made it even more intense. At the first turn, I climbed some 300 feet, and returning to altitude she accelerated to 219 knots (405 km/h). I felt extremely tense and had a hard time keeping the ball in the center. Overall I am happy that I managed to fly a pretty good course. On the straight course, we got 212 knots average speed. It was great to celebrate the success with my co-pilot Fredrik Lanz, and the rest of the Blackwing team.

“On Tuesday the weather conditions were perfect. We decided to fly at 10,000 feet. The [FAI] criteria that the course could only be flown once made it even more intense. At the first turn, I climbed some 300 feet, and returning to altitude she accelerated to 219 knots (405 km/h). I felt extremely tense and had a hard time keeping the ball in the center. Overall I am happy that I managed to fly a pretty good course. On the straight course, we got 212 knots average speed. It was great to celebrate the success with my co-pilot Fredrik Lanz, and the rest of the Blackwing team. “The flight testing will continue in spring and summer. After 50 hours of flight testing, we can start taking passengers.

“The flight testing will continue in spring and summer. After 50 hours of flight testing, we can start taking passengers. “JMB Aircraft is proud to announce some achievements from the past few months,” the company wrote recently. “After more than 100 hours of flight test with two planes, we manage with success to perform a V-dive test reaching an indicated 381 kilometers per hour and 425 km/h (229 knots) true air speed. This enable us to safely increase our VNE up to an indicated 340 kilometers per hour (184 knots).”

“JMB Aircraft is proud to announce some achievements from the past few months,” the company wrote recently. “After more than 100 hours of flight test with two planes, we manage with success to perform a V-dive test reaching an indicated 381 kilometers per hour and 425 km/h (229 knots) true air speed. This enable us to safely increase our VNE up to an indicated 340 kilometers per hour (184 knots).” I suspect the LSA-like airspeed race isn’t over yet, especially given the previous record holder — Risen, from a formerly Swiss, now Italian company renamed as

I suspect the LSA-like airspeed race isn’t over yet, especially given the previous record holder — Risen, from a formerly Swiss, now Italian company renamed as

I am pleased to serve a need for news during a month when we should have been covering

I am pleased to serve a need for news during a month when we should have been covering  Several sources close to EAA leadership have said a decision will come in early May, however, it doesn’t take a genius to figure that. EAA is grappling with matters such as when hundreds of tents or thousands of portable bathrooms must be ordered, or finalizing the call to a not-small army of volunteers to begin the trek to Wisconsin. Such major plans must be started well in advance of the event slated for July 20-26th.

Several sources close to EAA leadership have said a decision will come in early May, however, it doesn’t take a genius to figure that. EAA is grappling with matters such as when hundreds of tents or thousands of portable bathrooms must be ordered, or finalizing the call to a not-small army of volunteers to begin the trek to Wisconsin. Such major plans must be started well in advance of the event slated for July 20-26th. A prime motivator for E-Fan is Grazia Vittadini, Airbus’ Chief Technology Officer. She wrote, “When I first started my career at Airbus, the notion of electric flight was considered a far-off pipedream. Today, it’s a reality.” Yet that future may not involve their much-promoted E-Fan.

A prime motivator for E-Fan is Grazia Vittadini, Airbus’ Chief Technology Officer. She wrote, “When I first started my career at Airbus, the notion of electric flight was considered a far-off pipedream. Today, it’s a reality.” Yet that future may not involve their much-promoted E-Fan.

Now, a

Now, a  Even during the lockdown,

Even during the lockdown,  While the following information covers only one quarter of the year and while it does not reflect much of the pandemic effects, we nonetheless found a few tidbits of interest. For the data hounds among you, we invite you to visit our market share and airplane registration database website called

While the following information covers only one quarter of the year and while it does not reflect much of the pandemic effects, we nonetheless found a few tidbits of interest. For the data hounds among you, we invite you to visit our market share and airplane registration database website called  Among Special (fully-built) LSA registrations,

Among Special (fully-built) LSA registrations,

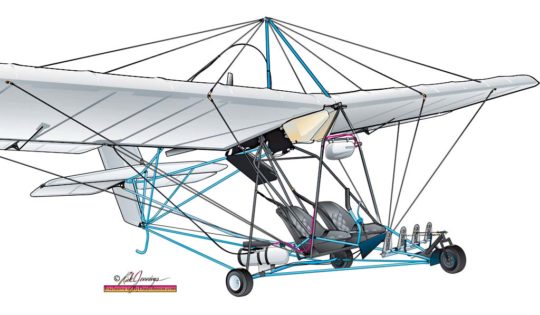

Ernie was the man behind Carlson Aircraft along with his wife, Mary. This pair introduced Sparrow, a Part 103-capable single-place ultralight plus larger models like Sparrow II and XTC.

Ernie was the man behind Carlson Aircraft along with his wife, Mary. This pair introduced Sparrow, a Part 103-capable single-place ultralight plus larger models like Sparrow II and XTC. “In the next couple weeks, we will get our website up and running,” he forecast, but until then David invites a call or text to 574-214-3660 or theecoop@comcast.net.

“In the next couple weeks, we will get our website up and running,” he forecast, but until then David invites a call or text to 574-214-3660 or theecoop@comcast.net. In addition, for Carlson airplanes already built and flying, David and partners’ new operation will offer replacement parts. I’m sure that will be most welcome by those flying Carlson aircraft.

In addition, for Carlson airplanes already built and flying, David and partners’ new operation will offer replacement parts. I’m sure that will be most welcome by those flying Carlson aircraft.

As alert readers may have noticed, Mini-Max shares something with the

As alert readers may have noticed, Mini-Max shares something with the  “When I asked why Wayne moved to Tennessee from Indiana, Scott recalls, Wayne replied, ‘Winters were too brutal. So I put my snow shovel in the back of my pickup truck and headed south. When they no longer recognized what that shovel was, I figured I was safe. That was Tennessee.’” It sounds just like my memory of the man — logical, simple, decisive.

“When I asked why Wayne moved to Tennessee from Indiana, Scott recalls, Wayne replied, ‘Winters were too brutal. So I put my snow shovel in the back of my pickup truck and headed south. When they no longer recognized what that shovel was, I figured I was safe. That was Tennessee.’” It sounds just like my memory of the man — logical, simple, decisive. Videoman Dave wrote, “In 1984, while attending the Sun ‘n Fun convention, I watched as a little single seat ultralight aircraft took to the air in some very gusty, cross-wind conditions. These were conditions that had grounded most of the other ultralight aircraft on the field,” yet off into the air went this very light and surprisingly compact ultralight aircraft. Dave refers to Wayne’s Mini-Max of course.

Videoman Dave wrote, “In 1984, while attending the Sun ‘n Fun convention, I watched as a little single seat ultralight aircraft took to the air in some very gusty, cross-wind conditions. These were conditions that had grounded most of the other ultralight aircraft on the field,” yet off into the air went this very light and surprisingly compact ultralight aircraft. Dave refers to Wayne’s Mini-Max of course. Build time is between 250 and 350 hours. Mini-Max can be built in a small area such as a single car garage. No special tools or equipment needed because much like the Fisher aircraft that had Wayne’s hand in them, Mini-Max plans were full-sized; you work directly on very large sheets of paper. This helps newbies but also ensures greater accuracy as builders work to put all the “popsicle sticks” in exactly the right locations.

Build time is between 250 and 350 hours. Mini-Max can be built in a small area such as a single car garage. No special tools or equipment needed because much like the Fisher aircraft that had Wayne’s hand in them, Mini-Max plans were full-sized; you work directly on very large sheets of paper. This helps newbies but also ensures greater accuracy as builders work to put all the “popsicle sticks” in exactly the right locations. The Mini-Max line of aircraft has a strong following on the Internet. “Thousands of kits have been sold and are flying throughout the world,” said Dave.

The Mini-Max line of aircraft has a strong following on the Internet. “Thousands of kits have been sold and are flying throughout the world,” said Dave. Cruise is an honest 55 to 60 miles per hour and stall speed is roughly 25 miles per hour.

Cruise is an honest 55 to 60 miles per hour and stall speed is roughly 25 miles per hour. At the time of production of this video

At the time of production of this video

During this coronavirus mess, Sweden has been in the news because authorities did not fully lock down the country. Some closures were recommended and certain folks (older, immune-deficient… you’ve heard all this repeatedly) were encouraged to self-isolate. Yet pictures show restaurants, streets, and other public venues with plenty of people. Sweden has had deaths, of course, every one of them tragic. Yet it will provide a good baseline with which to judge the effectiveness of lockdown procedures from draconian to… well, Swedish.

During this coronavirus mess, Sweden has been in the news because authorities did not fully lock down the country. Some closures were recommended and certain folks (older, immune-deficient… you’ve heard all this repeatedly) were encouraged to self-isolate. Yet pictures show restaurants, streets, and other public venues with plenty of people. Sweden has had deaths, of course, every one of them tragic. Yet it will provide a good baseline with which to judge the effectiveness of lockdown procedures from draconian to… well, Swedish.

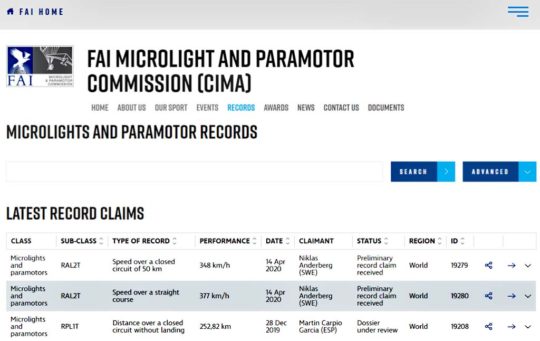

The two pilots from the south of Sweden set two new world records and have filed for FAI (Fédération Aéronautique Internationale) recognition.

The two pilots from the south of Sweden set two new world records and have filed for FAI (Fédération Aéronautique Internationale) recognition. While laying claim to two new world records, to gain proper recognition of their achievement, the performance must now be checked and approved by the International Aviation Sports Association,

While laying claim to two new world records, to gain proper recognition of their achievement, the performance must now be checked and approved by the International Aviation Sports Association,  For the official record in Class UL aircraft RAL2T (Movable Aerodynamic Control / Landplane / Flown with two persons / Thermal Engine), previously recognized record holders include:

For the official record in Class UL aircraft RAL2T (Movable Aerodynamic Control / Landplane / Flown with two persons / Thermal Engine), previously recognized record holders include:

“The quality and finish of his aircraft and kits has to be seen to be appreciated,” Dave added. I completely agree. I have often told Randy how I admired the factory finish of the airplanes he presents to interested pilots at airshows. A stickler for getting it right, Randy demurs my admiration but anyone who has closely examined his models at an event knows I am not exaggerating.

“The quality and finish of his aircraft and kits has to be seen to be appreciated,” Dave added. I completely agree. I have often told Randy how I admired the factory finish of the airplanes he presents to interested pilots at airshows. A stickler for getting it right, Randy demurs my admiration but anyone who has closely examined his models at an event knows I am not exaggerating. Then and today, most Rans models have been made available in both tricycle gear and taildragger configurations.

Then and today, most Rans models have been made available in both tricycle gear and taildragger configurations.  Kit assembly time for these fairly simple aircraft was between 100 and 125 hours. “Rans’ manuals and instructional building guides lead the industry in completeness,” expressed Dave. “No special tools or jigs are required to build the planes and they can be built in a single car garage.”

Kit assembly time for these fairly simple aircraft was between 100 and 125 hours. “Rans’ manuals and instructional building guides lead the industry in completeness,” expressed Dave. “No special tools or jigs are required to build the planes and they can be built in a single car garage.” Cruise speed in S-4/5 is 55 to 60 miles per hour while stall, using optimal flaps, is 25 miles per hour.

Cruise speed in S-4/5 is 55 to 60 miles per hour while stall, using optimal flaps, is 25 miles per hour.

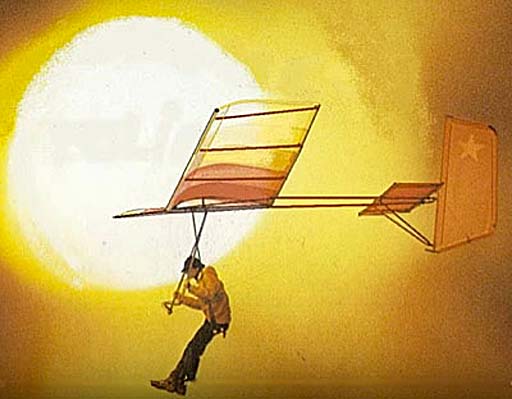

The MX model abandoned the weight shift idea — this was too foreign to lots of potential customers. Instead, it used stick-and-rudder two-axis controls, but with a difference. The joystick connected to the elevator and rudder while the rudder pedals were connected to spoilerons on top of the wing.

The MX model abandoned the weight shift idea — this was too foreign to lots of potential customers. Instead, it used stick-and-rudder two-axis controls, but with a difference. The joystick connected to the elevator and rudder while the rudder pedals were connected to spoilerons on top of the wing.

The Coronavirus madness is far from being a U.S. problem. Naturally, we tend to focus on our own part of the world …as we must. Yet even far-away countries are also struggling — to protect citizens and to keep their economies afloat. It simply has to improve as the present situation cannot last.

The Coronavirus madness is far from being a U.S. problem. Naturally, we tend to focus on our own part of the world …as we must. Yet even far-away countries are also struggling — to protect citizens and to keep their economies afloat. It simply has to improve as the present situation cannot last. “Along with much of the world,” Paul continued in early April, “New Zealand is feeling the effects of the Covid-19 pandemic with a state of emergency declared. With this four-week lockdown all non-essential companies are required to close or work from home.”

“Along with much of the world,” Paul continued in early April, “New Zealand is feeling the effects of the Covid-19 pandemic with a state of emergency declared. With this four-week lockdown all non-essential companies are required to close or work from home.” “While our technicians and workshop staff are safe at home with their families, our designers are using this time and working from their homes to finalise the remaining aspects of the design, prepare work and plan the actions required once we are able to get all staff safely back to work,” observed Paul.

“While our technicians and workshop staff are safe at home with their families, our designers are using this time and working from their homes to finalise the remaining aspects of the design, prepare work and plan the actions required once we are able to get all staff safely back to work,” observed Paul. “Not currently being reliant on sales and having investors with long term vision makes Vickers a stable and strong company in this environment,” explained Paul.

“Not currently being reliant on sales and having investors with long term vision makes Vickers a stable and strong company in this environment,” explained Paul. Earlier

Earlier

To gain perspective on the history of this well-regarded design, I reached out to an old friend who had extensive early experience with the original company located not far from his home.

To gain perspective on the history of this well-regarded design, I reached out to an old friend who had extensive early experience with the original company located not far from his home. “Immediately after seeing these bright colored flying toys at Skylark, I rode my motorcycle to Windsor Connecticut where the Ultralight Flight Inc., facility was quartered. Ultralight Flight was housed in a old building of about 2,000 square feet that used to be summer housing for migrant tobacco pickers.

“Immediately after seeing these bright colored flying toys at Skylark, I rode my motorcycle to Windsor Connecticut where the Ultralight Flight Inc., facility was quartered. Ultralight Flight was housed in a old building of about 2,000 square feet that used to be summer housing for migrant tobacco pickers. “Within a couple of hours of seeing the planes at Skylark, I had a new job in the ‘machine shop’ of Ultralight Flight. I made pretty much all the tooling to cut, drill, and bend aluminum tubing, make plastic bushings, and a wire jig for upper and lower wing wires and control cables for the Mirage.

“Within a couple of hours of seeing the planes at Skylark, I had a new job in the ‘machine shop’ of Ultralight Flight. I made pretty much all the tooling to cut, drill, and bend aluminum tubing, make plastic bushings, and a wire jig for upper and lower wing wires and control cables for the Mirage. “Within a couple of months after the show, we had tooled up and set up a dealer network across the country that produced sales of 10 to 20 birds a week,” Ken noted with enthusiasm! “We had a pretty well oiled machine and could really pump out kits.”

“Within a couple of months after the show, we had tooled up and set up a dealer network across the country that produced sales of 10 to 20 birds a week,” Ken noted with enthusiasm! “We had a pretty well oiled machine and could really pump out kits.” “About nine months later, when all of the load testing and checks and measures were done, we brought the new Phantom out to Skylark Airport for test flights. It was a pretty awesome time. It was an amazing flying machine, going well beyond Mirage.

“About nine months later, when all of the load testing and checks and measures were done, we brought the new Phantom out to Skylark Airport for test flights. It was a pretty awesome time. It was an amazing flying machine, going well beyond Mirage.

At the time of production of the following video The Ultralight Flyer would estimate the value of a used Phantom from the 1980s to be worth between $4,500 and $6,500.

At the time of production of the following video The Ultralight Flyer would estimate the value of a used Phantom from the 1980s to be worth between $4,500 and $6,500.

Lazair entered the market in the early 1980s and was sold in kit form. Kits took between 500 and 1,000 hours to build as they were basically a raw materials kit. The fuselage and tail section use aluminum tubing with bolt and rivet construction.

Lazair entered the market in the early 1980s and was sold in kit form. Kits took between 500 and 1,000 hours to build as they were basically a raw materials kit. The fuselage and tail section use aluminum tubing with bolt and rivet construction. Power was originally supplied by two modified Pioneer Chainsaw engines of approximately 5.5 horsepower each. The Series 2 and 3 models used two, single-cylinder, 9.5-horsepower Rotax engines. These engines were mounted on the leading edge of the wings.

Power was originally supplied by two modified Pioneer Chainsaw engines of approximately 5.5 horsepower each. The Series 2 and 3 models used two, single-cylinder, 9.5-horsepower Rotax engines. These engines were mounted on the leading edge of the wings. Climb rate on the Lazair Series 2 and 3 ultralights was approximately 450 to 500 feet per minute. Cruise speed was between 35 and 45 miles per hour. Stall is around 25 miles per hour.

Climb rate on the Lazair Series 2 and 3 ultralights was approximately 450 to 500 feet per minute. Cruise speed was between 35 and 45 miles per hour. Stall is around 25 miles per hour. From comments to

From comments to  “Pioneer engines are under powered,” galactica one noted. “The Rotax 185s are good engines, parts are available, and performance is adequate. They should be upgraded to around 30 horsepower total,” the commenter added, as “two engines in the 15-horsepower range would give Lazair proper performance.”

“Pioneer engines are under powered,” galactica one noted. “The Rotax 185s are good engines, parts are available, and performance is adequate. They should be upgraded to around 30 horsepower total,” the commenter added, as “two engines in the 15-horsepower range would give Lazair proper performance.”

Of course, I refer to

Of course, I refer to  Bristell with

Bristell with  Representative U.S. Sport Planes, led by industry veteran Scott Severen, has demonstrated this baggage capacity with photos showing a

Representative U.S. Sport Planes, led by industry veteran Scott Severen, has demonstrated this baggage capacity with photos showing a  Since I first saw the F2 in mock up, Flight Design has redesigned the intake for two reasons: “to reduce drag as we confirmed the older version was very functional but draggy; and for aesthetic reasons,” said the company. “Flight Design team designer and Head of Airworthiness, Christian Majunke, designed conceptually. He also designed a rather novel installation of the coolant and oil radiators,” elaborated Flight Design USA representative, Tom Peghiny.

Since I first saw the F2 in mock up, Flight Design has redesigned the intake for two reasons: “to reduce drag as we confirmed the older version was very functional but draggy; and for aesthetic reasons,” said the company. “Flight Design team designer and Head of Airworthiness, Christian Majunke, designed conceptually. He also designed a rather novel installation of the coolant and oil radiators,” elaborated Flight Design USA representative, Tom Peghiny. At Sun ‘n Fun 2020, Deon expected to introduce Whisper to American kit builders. Alas, as with the rest of this group, you probably won’t see it until July in Wisconsin.

At Sun ‘n Fun 2020, Deon expected to introduce Whisper to American kit builders. Alas, as with the rest of this group, you probably won’t see it until July in Wisconsin. Bruno will be aided in his approach to the U.S. market by longtimer, Ed Ricks, who once helped the Paradise Aircraft people with their

Bruno will be aided in his approach to the U.S. market by longtimer, Ed Ricks, who once helped the Paradise Aircraft people with their

The FireStar is a high wing, strut braced, taildragger in a pusher configuration. To some aviators, “taildragger” is a negative. However…

The FireStar is a high wing, strut braced, taildragger in a pusher configuration. To some aviators, “taildragger” is a negative. However… If you prefer new to a used aircraft, the modern Part-103 compliant Kolb Firefly won’t cost you as much as you might think. However, the Kentucky factory is busy building these aircraft, so a ready-to-fly model might be a few months coming. Part 103 ultralights are quietly out-selling many other types and for good reasons: they are proven, inexpensive, and involve almost no FAA regulations.

If you prefer new to a used aircraft, the modern Part-103 compliant Kolb Firefly won’t cost you as much as you might think. However, the Kentucky factory is busy building these aircraft, so a ready-to-fly model might be a few months coming. Part 103 ultralights are quietly out-selling many other types and for good reasons: they are proven, inexpensive, and involve almost no FAA regulations. Power for used Firestar will likely be supplied by the Rotax 377, 447, or 503 two-stroke aircraft engines, however, a variety of engines from 28 to 55 horsepower have been used.

Power for used Firestar will likely be supplied by the Rotax 377, 447, or 503 two-stroke aircraft engines, however, a variety of engines from 28 to 55 horsepower have been used.

As it turns out, the Sorrel Hiperlight SNS 8 was originally designed at the request of Ron Schettler, the first Canadian Distributor of

As it turns out, the Sorrel Hiperlight SNS 8 was originally designed at the request of Ron Schettler, the first Canadian Distributor of  SNS 8 is offered in kit form. It features a two piece 4130-welded steel fuselage, which can be separated for ease of storage. The aircraft can be covered in pre-sewn Dacron sail cloth envelopes or by the use of standard aircraft covering materials. Building times are in the 150 to 400 hour range, with the conventional fabric covering taking longer to complete.

SNS 8 is offered in kit form. It features a two piece 4130-welded steel fuselage, which can be separated for ease of storage. The aircraft can be covered in pre-sewn Dacron sail cloth envelopes or by the use of standard aircraft covering materials. Building times are in the 150 to 400 hour range, with the conventional fabric covering taking longer to complete. Thunderbird Aviation was established officially in 2002 by Ron Jones. He reported, “[We] offer aircraft that appeal to a wide range of interests …from an ultralight, to a two-place Experimental, to a fully aerobatic yet cross-country-capable machine, and soon to come will be the SLSA Version.”

Thunderbird Aviation was established officially in 2002 by Ron Jones. He reported, “[We] offer aircraft that appeal to a wide range of interests …from an ultralight, to a two-place Experimental, to a fully aerobatic yet cross-country-capable machine, and soon to come will be the SLSA Version.” Beside a Rotax 377 or 447, other engines that have powered the Hiperlight SNS 8 are Hirth, Kawasaki, and half-VW conversions.

Beside a Rotax 377 or 447, other engines that have powered the Hiperlight SNS 8 are Hirth, Kawasaki, and half-VW conversions.

Changes for 2020 include a reshaped and longer cowling, Blackline propeller with new spinner, fully integrated landing light, and an additional NACA inlet to improve cooling. Other aerodynamic improvements include new landing gear legs with internal brake lines and new low drag wheel fairings. This all leads to significantly reduced drag and an increase in maximum speed. The company reports, “[These] aerodynamic modifications have made the CTLS 2020 nearly 10 knots faster!”

Changes for 2020 include a reshaped and longer cowling, Blackline propeller with new spinner, fully integrated landing light, and an additional NACA inlet to improve cooling. Other aerodynamic improvements include new landing gear legs with internal brake lines and new low drag wheel fairings. This all leads to significantly reduced drag and an increase in maximum speed. The company reports, “[These] aerodynamic modifications have made the CTLS 2020 nearly 10 knots faster!” A new

A new  “Our F2 Light-Sport Aircraft model is fully ASTM-compliant after fine tuning,” noted the company. “Our first airplanes will be delivered to customers in June 2020. Careful engineering allowed us to bring this complex airplane under the maximum allowed take-off weight (of 1,320 pounds or 600 kilograms).”

“Our F2 Light-Sport Aircraft model is fully ASTM-compliant after fine tuning,” noted the company. “Our first airplanes will be delivered to customers in June 2020. Careful engineering allowed us to bring this complex airplane under the maximum allowed take-off weight (of 1,320 pounds or 600 kilograms).” Late in 2017, a Flight Design review concluded that prepregs could deliver a more consistent final product by ensuring constant material quality and processing parameters and could produce a lighter and stronger aircraft at a more competitive overall cost. The low-temperature cure could be done outside an autoclave. The latter reduces tooling costs and can boost build rates. Following careful analysis, the company went with Hexcel. Prepreg materials — “pre-impregnated” composite fibers have an epoxy material already present — were first used for the F2 prototype.

Late in 2017, a Flight Design review concluded that prepregs could deliver a more consistent final product by ensuring constant material quality and processing parameters and could produce a lighter and stronger aircraft at a more competitive overall cost. The low-temperature cure could be done outside an autoclave. The latter reduces tooling costs and can boost build rates. Following careful analysis, the company went with Hexcel. Prepreg materials — “pre-impregnated” composite fibers have an epoxy material already present — were first used for the F2 prototype. Flight Design began to review the market for available material options with a key part of its strategy to find and qualify a prepreg system that is not traditionally used in higher cost autoclave production for aerospace applications.

Flight Design began to review the market for available material options with a key part of its strategy to find and qualify a prepreg system that is not traditionally used in higher cost autoclave production for aerospace applications. Already in operation since March 1st, Flight Design will “offset” the carbon emissions from the fuel burned by their airplanes during the first 2,000 hours of operation. They’ll do this by employing the

Already in operation since March 1st, Flight Design will “offset” the carbon emissions from the fuel burned by their airplanes during the first 2,000 hours of operation. They’ll do this by employing the  Offsets will come from cash contributions by Flight Design to programs that meet internationally-accepted standards. Funds will be deployed to planting more trees and other actions that consume CO2.

Offsets will come from cash contributions by Flight Design to programs that meet internationally-accepted standards. Funds will be deployed to planting more trees and other actions that consume CO2.

The look it presents when assembled but not covered is that resembling construction of a geodesic dome, except flat. It looks like a daunting build but you just put piece after piece in place, right on the drawing, until all the “popsicle sticks” are in place. The process is not unlike color-by-the-numbers as little kids do.

The look it presents when assembled but not covered is that resembling construction of a geodesic dome, except flat. It looks like a daunting build but you just put piece after piece in place, right on the drawing, until all the “popsicle sticks” are in place. The process is not unlike color-by-the-numbers as little kids do. The charming, highly-affordable, all-wood Koala was designed by Mike Fisher and Wayne Ison in the early 1980s. Yes, the same, one-and-only Wayne Ison associated with Team Aircraft, another builder of light weight, low-cost, nearly-all-wood designs. We will present an article and video on Team’s MiniMax later on on the Ultralight April 2020 Vintage series.

The charming, highly-affordable, all-wood Koala was designed by Mike Fisher and Wayne Ison in the early 1980s. Yes, the same, one-and-only Wayne Ison associated with Team Aircraft, another builder of light weight, low-cost, nearly-all-wood designs. We will present an article and video on Team’s MiniMax later on on the Ultralight April 2020 Vintage series. From the beginning Fisher and Ison designed Koala to fit

From the beginning Fisher and Ison designed Koala to fit  We can have you in a plane for the price of a used Harley motorcycle, said

We can have you in a plane for the price of a used Harley motorcycle, said

Hawk was the first ultralight to be fully enclosed, meaning it had a floor, meaning you could not foot-launch it. The rule was still in place when Chuck first debuted Hawk but that one aircraft lead us into the brave new world of wheel-launching.

Hawk was the first ultralight to be fully enclosed, meaning it had a floor, meaning you could not foot-launch it. The rule was still in place when Chuck first debuted Hawk but that one aircraft lead us into the brave new world of wheel-launching. The point of this series of short (5-minute) videos is to identify aircraft almost anyone can afford. I should not have to say it, but please don’t assume a $5,000, decades-old ultralight will compare well to a modern LSA. The good news is that, in some ways, such a low-cost aircraft might even be more fun assuming you use good judgement about when and where to fly.

The point of this series of short (5-minute) videos is to identify aircraft almost anyone can afford. I should not have to say it, but please don’t assume a $5,000, decades-old ultralight will compare well to a modern LSA. The good news is that, in some ways, such a low-cost aircraft might even be more fun assuming you use good judgement about when and where to fly.

In recent months many light aviation enthusiasts have been asking about progress on FAA’s proposed rewrite of the Light-Sport Aircraft regulations. Following a lengthy teleconference in 2019, the

In recent months many light aviation enthusiasts have been asking about progress on FAA’s proposed rewrite of the Light-Sport Aircraft regulations. Following a lengthy teleconference in 2019, the  FAA is moving forward on the rulemaking project yet everything remains in progress while the agency gathers internal assessments. What follows is as accurate as possible at this time but changes will occur.

FAA is moving forward on the rulemaking project yet everything remains in progress while the agency gathers internal assessments. What follows is as accurate as possible at this time but changes will occur. FAA generally agreed with our back-calendar estimate that the NPRM may be forthcoming in late 2021 or early 2022. This was based on the perceived amount of work remaining.

FAA generally agreed with our back-calendar estimate that the NPRM may be forthcoming in late 2021 or early 2022. This was based on the perceived amount of work remaining. A number of pilots and aircraft developers, surprised by the large potential increase in weight, have wondered what will keep these aircraft from becoming very large. If FAA will not specify a weight, what will prevent LSA 2023 from becoming heavier aircraft beyond the scope of LSA and the Sport Pilot certificate?

A number of pilots and aircraft developers, surprised by the large potential increase in weight, have wondered what will keep these aircraft from becoming very large. If FAA will not specify a weight, what will prevent LSA 2023 from becoming heavier aircraft beyond the scope of LSA and the Sport Pilot certificate? At present, FAA has given no specifics on speed, but reading between the lines, LAMA expects maximum flight speeds could be 140-150 knots.

At present, FAA has given no specifics on speed, but reading between the lines, LAMA expects maximum flight speeds could be 140-150 knots. However, matters regarding operation of LSA falls under Flight Standards, the people who manage Part 61 (airmen certification) and Part 65 (mechanics).

However, matters regarding operation of LSA falls under Flight Standards, the people who manage Part 61 (airmen certification) and Part 65 (mechanics). If the Ip value worked out to be less than 1.2, it was proposed at one point that the aircraft would fit within the definition of a Light Sport Aircraft. This formula would only work for airplanes, not applying to rotorcraft, powered parachutes and weight shift control trikes.

If the Ip value worked out to be less than 1.2, it was proposed at one point that the aircraft would fit within the definition of a Light Sport Aircraft. This formula would only work for airplanes, not applying to rotorcraft, powered parachutes and weight shift control trikes. However, there is a very simple explanation for the lack of sensitivity of the formula to weight. And in fact, the explanation comes from algebraically simplifying the equation itself. When you do that, you find that even though weight appears in the original equation, it quickly drops out since it is in both the numerator and the denominator.

However, there is a very simple explanation for the lack of sensitivity of the formula to weight. And in fact, the explanation comes from algebraically simplifying the equation itself. When you do that, you find that even though weight appears in the original equation, it quickly drops out since it is in both the numerator and the denominator. As an example, the wing area of a Flight Design CTSW is 107.0 square feet indicating that it is considerably larger than the minimum 57.87 square feet defined by an Ip of 1.2.

As an example, the wing area of a Flight Design CTSW is 107.0 square feet indicating that it is considerably larger than the minimum 57.87 square feet defined by an Ip of 1.2.

A frequent comment I hear is that the price of recreational aircraft are too high. Some pilots have been stating this for 18 years, since a couple years before Light-Sport Aircraft emerged.

A frequent comment I hear is that the price of recreational aircraft are too high. Some pilots have been stating this for 18 years, since a couple years before Light-Sport Aircraft emerged. Throughout aviation history, airplane builders worked hard to shave pounds, ounces, or grams from their designs. If light is right, then ultralights do it best.

Throughout aviation history, airplane builders worked hard to shave pounds, ounces, or grams from their designs. If light is right, then ultralights do it best. Yet for many, the Buccaneer XA could be a load of fun for just the right price. Plus,

Yet for many, the Buccaneer XA could be a load of fun for just the right price. Plus,  One of the top-rated ultralight aircraft, ‘er… vehicles, of the early 1980s was the Buccaneer amphibian.

One of the top-rated ultralight aircraft, ‘er… vehicles, of the early 1980s was the Buccaneer amphibian. First introduced in 1984, Buccaneer XA was the first amphibious single-hull ultralight to enter the market. It featured bolt-together aluminum tubing for the main frame fuselage, with a center mounted fiberglass hull bolted to it. Buccaneer’s wings, tail section, ailerons and rear fuselage were also constructed using aluminum tubing joined by gusset plates and bolt joints, then covered with slip-on, sewn-Dacron sailcloth “envelopes.”

First introduced in 1984, Buccaneer XA was the first amphibious single-hull ultralight to enter the market. It featured bolt-together aluminum tubing for the main frame fuselage, with a center mounted fiberglass hull bolted to it. Buccaneer’s wings, tail section, ailerons and rear fuselage were also constructed using aluminum tubing joined by gusset plates and bolt joints, then covered with slip-on, sewn-Dacron sailcloth “envelopes.” Power was originally supplied by the then-popular Rotax 277, a 28-horsepower, two-stroke engine. Later models were powered by the Rotax 377, 447 and 503 engines. All these were discontinued by

Power was originally supplied by the then-popular Rotax 277, a 28-horsepower, two-stroke engine. Later models were powered by the Rotax 377, 447 and 503 engines. All these were discontinued by  You should also throughly inspect the airframe, wings, landing gear, and the control systems.

You should also throughly inspect the airframe, wings, landing gear, and the control systems.

“Two years of hard job, more than 20 years of specific experience in this sector, invested into this new project. This new plane represents the sum of our vision, the expectations and needs coming from our customers and the desires of the STOL market. Design and elegance, innovations and safety, improved aerodynamics and performance, enhanced cabin comfort with new cargo capacity, reliability and strength, functionality and the potential to deliver new adventures, all come together quite well mixed.”

“Two years of hard job, more than 20 years of specific experience in this sector, invested into this new project. This new plane represents the sum of our vision, the expectations and needs coming from our customers and the desires of the STOL market. Design and elegance, innovations and safety, improved aerodynamics and performance, enhanced cabin comfort with new cargo capacity, reliability and strength, functionality and the potential to deliver new adventures, all come together quite well mixed.” “Norden is a name used to identify the beautiful Nordic and Scandinavian countries — Iceland, Norway, Sweden, Denmark, Finland. These incredible lands, with northern Canada and Alaska, are linked to the concepts of adventure and STOL operations. It is no secret that true bush flying was invented in the genuine Northern Territories.” Great distances and remoteness helped Pasquale find a name that could both inspire great “adventures” and “long trips.”

“Norden is a name used to identify the beautiful Nordic and Scandinavian countries — Iceland, Norway, Sweden, Denmark, Finland. These incredible lands, with northern Canada and Alaska, are linked to the concepts of adventure and STOL operations. It is no secret that true bush flying was invented in the genuine Northern Territories.” Great distances and remoteness helped Pasquale find a name that could both inspire great “adventures” and “long trips.”

He also reported, “The standard tailwheel can now be upgraded to T3 tailwheel suspension system or even Acme Stinger. The standard bungee system can be upgraded with a custom made shock absorber system produced by one our dealers, or even with a more professional Acme Shock Pro Series system, designed for tough operations.”

He also reported, “The standard tailwheel can now be upgraded to T3 tailwheel suspension system or even Acme Stinger. The standard bungee system can be upgraded with a custom made shock absorber system produced by one our dealers, or even with a more professional Acme Shock Pro Series system, designed for tough operations.”