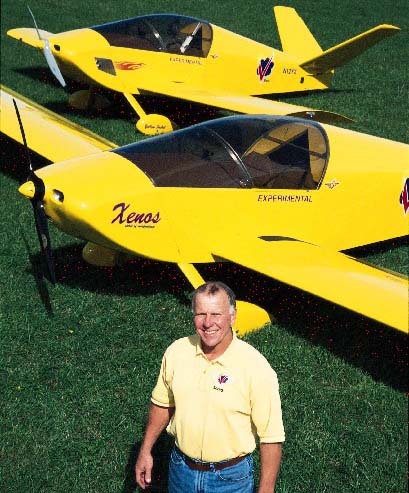

Early in June, John Monnett spoke about stepping down from Sonex Aircraft, the kit manufacturer he founded and has lead for decades. The company clarified, “After almost 50 years of involvement in the kit aircraft industry John has announced his retirement.” A Half Century of Achievement John’s roots in experimental aircraft date to 1968 when he was a young school teacher. After building a highly-modified Midget Mustang he was introduced to another Oshkosh legend, Steve Wittman (after whom the city airport is named). The two pioneers enjoyed a long friendship, which resulted in the development of Sonerai I, a Formula Vee racer that was John’s first design. Sonerai launched John into business. A half century later, he has many designs to his credit including several iterations of the Sonerai design, the Monerai sailplane, Moni motorglider, the world-record-holding Monex racer and a complete line of Sonex Aircraft models. Recognizing his work, John was inducted into the EAA Homebuilders Hall of Fame and is a two-time winner of the Dr.

The big Italian company that LSA enthusiasts know very well through models such as P92, Sierra, and P2008 has a large and growing presence in global aviation. Their developments are broad and delve into aviation segments large and small. They are also getting ready to celebrate a benchmark birthday.

This year Tecnam Costruzioni Aeronautiche — most pilots simply say “

The big Italian company that LSA enthusiasts know very well through models such as P92, Sierra, and P2008 has a large and growing presence in global aviation. Their developments are broad and delve into aviation segments large and small. They are also getting ready to celebrate a benchmark birthday.

This year Tecnam Costruzioni Aeronautiche — most pilots simply say “

The Leica CityMapper is specifically designed for 3D city modelling and urban mapping. It is the world’s first hybrid airborne sensor combining both oblique and nadir imaging as well as a LiDAR system.

Tecnam has a large staff to accomplish these diverse projects while building as many as four aircraft a week. Even with many employees, however, this is a impressive penetration of all aviation's nooks and crannies.

The Leica CityMapper is specifically designed for 3D city modelling and urban mapping. It is the world’s first hybrid airborne sensor combining both oblique and nadir imaging as well as a LiDAR system.

Tecnam has a large staff to accomplish these diverse projects while building as many as four aircraft a week. Even with many employees, however, this is a impressive penetration of all aviation's nooks and crannies.

BRM Aero boss and chief design, Milan Bristela, has convincingly proven his visionary credentials. Here's

BRM Aero boss and chief design, Milan Bristela, has convincingly proven his visionary credentials. Here's  All that space might be useful for another kind of enjoyment: bush flying, landing on river beds, camping …that sort of adventure.

For the new "bush" version of TDO, BRM again did a great job of finishing the interior, both in creature comforts (as seen in the nearby photo) or equipment.

To mount big Alaska tundra tires on their TDO, BRM teamed up with

All that space might be useful for another kind of enjoyment: bush flying, landing on river beds, camping …that sort of adventure.

For the new "bush" version of TDO, BRM again did a great job of finishing the interior, both in creature comforts (as seen in the nearby photo) or equipment.

To mount big Alaska tundra tires on their TDO, BRM teamed up with  What's great about the Beringer/Alaska adaptation is that it follows Milan's mantra to keep as many new innovations as possible retrofittable to older models. That works here, too, but owners get a bonus.

Through the design of this Bush TDO model, Milan made sure a mechanically-savvy owner can switch back and forth. Use your fiberglass gear and wheel pants to go fast for travel but swap to bush mode when you want to fly for fun on the weekend, maybe at your cottage. Cool, huh? What wonderful versatility.

What's great about the Beringer/Alaska adaptation is that it follows Milan's mantra to keep as many new innovations as possible retrofittable to older models. That works here, too, but owners get a bonus.

Through the design of this Bush TDO model, Milan made sure a mechanically-savvy owner can switch back and forth. Use your fiberglass gear and wheel pants to go fast for travel but swap to bush mode when you want to fly for fun on the weekend, maybe at your cottage. Cool, huh? What wonderful versatility.

U.S. representation is very strong with

U.S. representation is very strong with

"Oh, don't worry," your friend replies. "Just move the joystick as you'd expect. If anything goes wrong, just hit the big red button and it will safely return you to precisely where you took off."

"But what about the batteries …what I run low on juice?"

"Ah, don't sweat that either. The machine knows and it will land you safely before you run out of power."

Would you, the expert fixed wing pilot, take the offer? Would someone else who always wanted to fly, but who was put off by the challenges of learning to fly conventional aircraft, want to take the offer?

"Oh, don't worry," your friend replies. "Just move the joystick as you'd expect. If anything goes wrong, just hit the big red button and it will safely return you to precisely where you took off."

"But what about the batteries …what I run low on juice?"

"Ah, don't sweat that either. The machine knows and it will land you safely before you run out of power."

Would you, the expert fixed wing pilot, take the offer? Would someone else who always wanted to fly, but who was put off by the challenges of learning to fly conventional aircraft, want to take the offer?

Safety, low noise, performance, ease of control, and maintenance cost reduction are the selling points of Whisper, company officials said. They plan to move towards manufacture and marketing by 2020, hoping to sell ten machines in 2020, twenty in 2021, and forty in 2022. Those targets sound refreshingly sane to me, as opposed to other builders boasting huge volumes just over the horizon.

Current flight time is up to thirty minutes, they said, but representatives — like pretty much everybody else in the electric airplane development game — expect battery life to be increased with future technology.

An emergency parachute is part of the concept, however, it will also be possible to land in the case of a single rotor failure. It's actually quite believable that with eight motors/rotors, the loss of one could be fairly easily remedied with the others. It's just software …although that unveils the vulnerability in the near-future forecasts by some media.

Safety, low noise, performance, ease of control, and maintenance cost reduction are the selling points of Whisper, company officials said. They plan to move towards manufacture and marketing by 2020, hoping to sell ten machines in 2020, twenty in 2021, and forty in 2022. Those targets sound refreshingly sane to me, as opposed to other builders boasting huge volumes just over the horizon.

Current flight time is up to thirty minutes, they said, but representatives — like pretty much everybody else in the electric airplane development game — expect battery life to be increased with future technology.

An emergency parachute is part of the concept, however, it will also be possible to land in the case of a single rotor failure. It's actually quite believable that with eight motors/rotors, the loss of one could be fairly easily remedied with the others. It's just software …although that unveils the vulnerability in the near-future forecasts by some media.

Yes, of course. I

Yes, of course. I  Whatever the eventual solution, it has become more and more clear to me that multiple-rotor aircraft — some with wings that pivot to transition from vertical liftoff to speedier in-flight cruising — remain clearly in the future of flight.

I admit I am slowly being swayed from my love of conventional winged aircraft that I know so well to something with spinney or flippy propulsion. Oh, I don't see anything to replace the efficiency of fixed wings, for example, in the case of a gliding/soaring aircraft (think: sailplane or hang glider) but for many kinds of powered aircraft …well, the times, they may be a-changing.

I'll try not to overdo this reporting and for the next decade or so, developments will keep octocopters and such in the aerial lab, so to say. Meanwhile, the great news is that we have an embarrassment of riches with many choices of ultralights, light kit aircraft, and Light-Sport Aircraft. I hope you can enjoy one on this holiday!

And now… here is our video interview:

https://youtu.be/5kpsjjlR35k

Whatever the eventual solution, it has become more and more clear to me that multiple-rotor aircraft — some with wings that pivot to transition from vertical liftoff to speedier in-flight cruising — remain clearly in the future of flight.

I admit I am slowly being swayed from my love of conventional winged aircraft that I know so well to something with spinney or flippy propulsion. Oh, I don't see anything to replace the efficiency of fixed wings, for example, in the case of a gliding/soaring aircraft (think: sailplane or hang glider) but for many kinds of powered aircraft …well, the times, they may be a-changing.

I'll try not to overdo this reporting and for the next decade or so, developments will keep octocopters and such in the aerial lab, so to say. Meanwhile, the great news is that we have an embarrassment of riches with many choices of ultralights, light kit aircraft, and Light-Sport Aircraft. I hope you can enjoy one on this holiday!

And now… here is our video interview:

https://youtu.be/5kpsjjlR35k

For the moment, Brian is not designing. He's fighting for his very survival. …literally!

I am about to do something I never do on this website — for many reasons — but which I find worthy in this case. Let me have Brian's good buddy Jon Bailey tell you himself.

"I am a very close friend of Brian Austein. I am writing you to inform you that the day after Sun 'n Fun 2018 (on Monday April 16), Brian was diagnosed with Stage 4 lung cancer. It has moved into his brain. Brian is a fighter and he is fighting a tough battle right now. He is currently in Atlanta under evaluation for a second opinion. I will take him to another doctor on Tuesday (May 22nd) for his opinion.

"Please keep Brian and his family in your thoughts and prayers during this time.

For the moment, Brian is not designing. He's fighting for his very survival. …literally!

I am about to do something I never do on this website — for many reasons — but which I find worthy in this case. Let me have Brian's good buddy Jon Bailey tell you himself.

"I am a very close friend of Brian Austein. I am writing you to inform you that the day after Sun 'n Fun 2018 (on Monday April 16), Brian was diagnosed with Stage 4 lung cancer. It has moved into his brain. Brian is a fighter and he is fighting a tough battle right now. He is currently in Atlanta under evaluation for a second opinion. I will take him to another doctor on Tuesday (May 22nd) for his opinion.

"Please keep Brian and his family in your thoughts and prayers during this time.

"Dan, I know that you are well connected in the ultralight world and I know that a lot of ultralight people are amazed at what Brian has done. Can you share the attached Go Fund Me link? We set it up as a great way to give back and help out a man that has given so much to all of us."

Absolutely, Jon, I will put out the request and I have already contributed myself. Here's the

"Dan, I know that you are well connected in the ultralight world and I know that a lot of ultralight people are amazed at what Brian has done. Can you share the attached Go Fund Me link? We set it up as a great way to give back and help out a man that has given so much to all of us."

Absolutely, Jon, I will put out the request and I have already contributed myself. Here's the

From the beginning, Swan was planned with an enclosed cockpit so the pilot could be comfortable in low temperatures without needing a bulky flight suit. A cockpit heating system can be added as an option. Two ventilation systems are provided; one to prevent the windscreen fogging during taxi and another to supply fresh air. Alternatively, when the weather is hot, "the door can be simply removed," said Radu.

From the beginning, Swan was planned with an enclosed cockpit so the pilot could be comfortable in low temperatures without needing a bulky flight suit. A cockpit heating system can be added as an option. Two ventilation systems are provided; one to prevent the windscreen fogging during taxi and another to supply fresh air. Alternatively, when the weather is hot, "the door can be simply removed," said Radu.

Dogs in the Cockpit? A few years ago, various stories began to pop in mainstream media discussing the car industry's newest focus …no, not only on how many cup holders they could install in your new ride — but instead on accommodations for pets, mainly dogs.

Why?

Easy. Some high percentage of all auto trips include bringing the family pet along for the ride. Design to that and you sell more cars.

Does this apply to airplanes?

Think what you will of this, it's a fact of modern life in America. Surveys reveal that 44% of American household have a dog, some 78 million critters. More than half of all dog-owning households take their pets when they travel by car. That's a big market. Cars that can readily allow the family pup to come along — preferably not riding in the driver's lap with its nose out the window — will find many interested buyers.

Should airplanes be different?

Dogs in the Cockpit? A few years ago, various stories began to pop in mainstream media discussing the car industry's newest focus …no, not only on how many cup holders they could install in your new ride — but instead on accommodations for pets, mainly dogs.

Why?

Easy. Some high percentage of all auto trips include bringing the family pet along for the ride. Design to that and you sell more cars.

Does this apply to airplanes?

Think what you will of this, it's a fact of modern life in America. Surveys reveal that 44% of American household have a dog, some 78 million critters. More than half of all dog-owning households take their pets when they travel by car. That's a big market. Cars that can readily allow the family pup to come along — preferably not riding in the driver's lap with its nose out the window — will find many interested buyers.

Should airplanes be different?

Dogs do love to go for a ride. Our last pooch dug it so much she wouldn't leave the car even after we got home. She'd stay inside until you took her out.

So when Scott Severen, now the man behind Jabiru aircraft sales, gave reporters at Sun 'n Fun 2018 a thumb drive with a bunch of photos of dogs inside, I sensed a fun story.

His J-230D LSA sport plane can easily handle the spouse and the family pooch.

No wonder really, as Jabiru sells this same airframe as a four seat kit in Australia, hence a cavernous aft cabin. Three doors is an added bonus.

Jabiru's big third door aft of the pilot's door makes an easy task to load your luggage unlike most low wing airplanes where it can often be challenging. Inside the J-230D you can put several bags of golf clubs or a large amount of luggage or a folding bicycle or two …or a few less bags and the family dog. Even larger dogs won't be cramped.

Dogs do love to go for a ride. Our last pooch dug it so much she wouldn't leave the car even after we got home. She'd stay inside until you took her out.

So when Scott Severen, now the man behind Jabiru aircraft sales, gave reporters at Sun 'n Fun 2018 a thumb drive with a bunch of photos of dogs inside, I sensed a fun story.

His J-230D LSA sport plane can easily handle the spouse and the family pooch.

No wonder really, as Jabiru sells this same airframe as a four seat kit in Australia, hence a cavernous aft cabin. Three doors is an added bonus.

Jabiru's big third door aft of the pilot's door makes an easy task to load your luggage unlike most low wing airplanes where it can often be challenging. Inside the J-230D you can put several bags of golf clubs or a large amount of luggage or a folding bicycle or two …or a few less bags and the family dog. Even larger dogs won't be cramped.

I used to try this in a Cessna 150/150 (it had a 150-horse Lycoming up front). Our dog at the time weighed more than 100 pounds. Flying with two people and the dog meant a reduced fuel load but for short trips it was fine. Once inside, Sunny had plenty of room in the 150's ample baggage area, but getting the big guy in that space was a challenge.

In flight I used the baggage tie downs and a special dog harness to be sure he didn't get tossed around should we encounter turbulence. The harness also prevented him from distracting or interfering with the pilot. He didn't seem to mind; a few minutes into the flight, he would lay down and sleep.

Jabiru J-230D is way better, easier on you, the dog, and the airplane than my venerable Cessna 150.

I used to try this in a Cessna 150/150 (it had a 150-horse Lycoming up front). Our dog at the time weighed more than 100 pounds. Flying with two people and the dog meant a reduced fuel load but for short trips it was fine. Once inside, Sunny had plenty of room in the 150's ample baggage area, but getting the big guy in that space was a challenge.

In flight I used the baggage tie downs and a special dog harness to be sure he didn't get tossed around should we encounter turbulence. The harness also prevented him from distracting or interfering with the pilot. He didn't seem to mind; a few minutes into the flight, he would lay down and sleep.

Jabiru J-230D is way better, easier on you, the dog, and the airplane than my venerable Cessna 150.

I can think of quite a few other reasons you might want to have a closer look at

I can think of quite a few other reasons you might want to have a closer look at

Joe knows his light seaplanes. He’s built at least one Searey and he used to fly it daily from Spruce Creek to a lake in Tavares, Florida where Progressive Aerodyne manufactures Searey. For a couple years, Joe was CEO of the operation making him highly aware of this niche of airplanes.

Joe knows his light seaplanes. He’s built at least one Searey and he used to fly it daily from Spruce Creek to a lake in Tavares, Florida where Progressive Aerodyne manufactures Searey. For a couple years, Joe was CEO of the operation making him highly aware of this niche of airplanes.

Searey — The most established of the collection is this veteran design from

Searey — The most established of the collection is this veteran design from  AirCam — The lone floatplane of the group is also the only twin engine of the group yet this larger-than-life airplane still qualifies as a light aircraft, easily so. Given its modest weight, the presence of two Rotax 9-series engines on this kit makes it a formidable performer but one that can use that capability at slow speeds, making the airplane an absolute delight for the kind of low-elevation flying that many others aircraft should not attempt. Around 200 are flying. Kit builder

AirCam — The lone floatplane of the group is also the only twin engine of the group yet this larger-than-life airplane still qualifies as a light aircraft, easily so. Given its modest weight, the presence of two Rotax 9-series engines on this kit makes it a formidable performer but one that can use that capability at slow speeds, making the airplane an absolute delight for the kind of low-elevation flying that many others aircraft should not attempt. Around 200 are flying. Kit builder  Aero Adventure — The Aventura model, seen here in its new S-17 configuration, dates back as far as the Searay but because of ownership changes the design also evolved uniquely. Originally known as the Buccaneer, it became of the Aventura when Carlos Pereyra added his exceptional fiberglass skills to the hull. Current owner, Alex Rolinski, has taken the design into the CAD age and beefed up its performance. The S-17 model boasts a 117-horsepower AeroMomentum Suzuki-based engine and attractive options; the package has been attracting strong interest for

Aero Adventure — The Aventura model, seen here in its new S-17 configuration, dates back as far as the Searay but because of ownership changes the design also evolved uniquely. Originally known as the Buccaneer, it became of the Aventura when Carlos Pereyra added his exceptional fiberglass skills to the hull. Current owner, Alex Rolinski, has taken the design into the CAD age and beefed up its performance. The S-17 model boasts a 117-horsepower AeroMomentum Suzuki-based engine and attractive options; the package has been attracting strong interest for  Super Petrel — One of the most unique entries is the bi-wing Super Petrel LS from

Super Petrel — One of the most unique entries is the bi-wing Super Petrel LS from

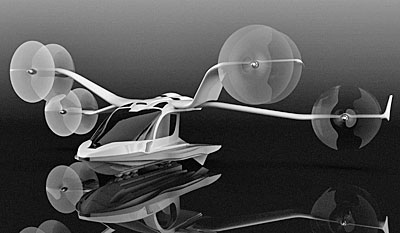

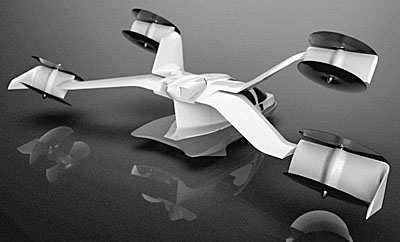

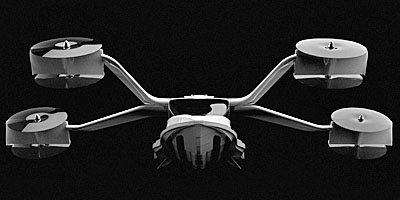

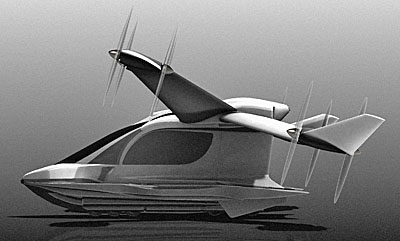

"Wave eVTOL is a four-seat, semi-autonomous hybrid and will harvest 80% of our Wave Light Sport Aircraft model’s DNA," said Paul. "This positions us well down the road of developing shared technology, components and tooling, R&D, materials, manufacturing processes, techniques, and facilities that we have been refining over the years for our LSA."

"Developing an eVTOL with amphibious capabilities opens possibilities not yet explored in this space, and with the New Zealand government leading the world from a regulation standpoint, New Zealand is on track to be the first country to allow approved manned eVTOL passenger flights."

Vickers Aircraft is working closely with the Civil Aviation Authority of New Zealand (CAANZ) throughout the development of the Wave LSA and eVTOL aircraft variants.

As you can see yourself, the proposed Wave eVTOL uses the multicopter approach with wing sections. They aren't the first to do this (

"Wave eVTOL is a four-seat, semi-autonomous hybrid and will harvest 80% of our Wave Light Sport Aircraft model’s DNA," said Paul. "This positions us well down the road of developing shared technology, components and tooling, R&D, materials, manufacturing processes, techniques, and facilities that we have been refining over the years for our LSA."

"Developing an eVTOL with amphibious capabilities opens possibilities not yet explored in this space, and with the New Zealand government leading the world from a regulation standpoint, New Zealand is on track to be the first country to allow approved manned eVTOL passenger flights."

Vickers Aircraft is working closely with the Civil Aviation Authority of New Zealand (CAANZ) throughout the development of the Wave LSA and eVTOL aircraft variants.

As you can see yourself, the proposed Wave eVTOL uses the multicopter approach with wing sections. They aren't the first to do this ( Anticipating a question readers might pose, I asked Paul if this new direction meant he was easing away from the fixed wing LSA.

"The initial design for the Wave was always to have a core base that can be used on a number of different models; the second in this range is the Wave eVTOL," Paul explained. "With facilities and technical ability already established [and with] wider government and regulatory support for the development of next generation aircraft in New Zealand, we feel confident in having a proof of concept ready by 2020."

The Wave LSA seaplane will come much sooner though Vickers Aircraft is cautious about promises given what they've observed from other companies in this space. He offered no update on the fixed wing model.

However, he is enthusiastic about using years of hard work to bring a one-design company closer to the family of aircraft he always foresaw.

Anticipating a question readers might pose, I asked Paul if this new direction meant he was easing away from the fixed wing LSA.

"The initial design for the Wave was always to have a core base that can be used on a number of different models; the second in this range is the Wave eVTOL," Paul explained. "With facilities and technical ability already established [and with] wider government and regulatory support for the development of next generation aircraft in New Zealand, we feel confident in having a proof of concept ready by 2020."

The Wave LSA seaplane will come much sooner though Vickers Aircraft is cautious about promises given what they've observed from other companies in this space. He offered no update on the fixed wing model.

However, he is enthusiastic about using years of hard work to bring a one-design company closer to the family of aircraft he always foresaw.

"The beauty of the Wave eVTOL is that it can be developed in parallel with [our] LSA, enabling us to maintain our schedule," said Paul. "Both models will share everything from components and tooling to ergonomics and storage, as well as manufacturing procedures and material allowables that will combine to result in a rapid development cycle."

To further communication on the new aircraft in planning, an organization called

"The beauty of the Wave eVTOL is that it can be developed in parallel with [our] LSA, enabling us to maintain our schedule," said Paul. "Both models will share everything from components and tooling to ergonomics and storage, as well as manufacturing procedures and material allowables that will combine to result in a rapid development cycle."

To further communication on the new aircraft in planning, an organization called  Two years ago at my favorite European airshow,

Two years ago at my favorite European airshow,  The truly good news for Yankees who might want to own such a creation is that Sportair USA boss Bill has placed an initial order. For a tiny company, such a launch customer greatly increases the likelihood that this unqiue entry will makes it way into American skies. Of course, Europeans also recognize both the F4U resemblance and the coolness of this design effort.

While fabric covered (also for lightness), Jörg refers to his internal carbon fiber tube structure as "a unique carbon-spaceframe technology." He added, "This property right-protected technology combines high strength with an unequaled low weight."

Seeking a very low weight is partly a maneuver to steer clear of tough certification rules via the Part 103 / 120-Kilo Class / SSDR

The truly good news for Yankees who might want to own such a creation is that Sportair USA boss Bill has placed an initial order. For a tiny company, such a launch customer greatly increases the likelihood that this unqiue entry will makes it way into American skies. Of course, Europeans also recognize both the F4U resemblance and the coolness of this design effort.

While fabric covered (also for lightness), Jörg refers to his internal carbon fiber tube structure as "a unique carbon-spaceframe technology." He added, "This property right-protected technology combines high strength with an unequaled low weight."

Seeking a very low weight is partly a maneuver to steer clear of tough certification rules via the Part 103 / 120-Kilo Class / SSDR  A light design permits Jörg's design objectives. "Due to the light weight of the structure we were able to include all the ingredients for a high performance aircraft: outstanding aerodynamics, a strong engine with a big, efficient propeller, a short and aerodynamic landing gear, as well as effective flaperons."

The carbon-spaceframe is effective, resulting in a calculated +9 and –6g ultimate load strength. "Furthermore," Jörg said, "the complete cockpit area is constructed as a Kevlar-reinforced safety cell." A ballistic parachute will further enhance safety.

In our

A light design permits Jörg's design objectives. "Due to the light weight of the structure we were able to include all the ingredients for a high performance aircraft: outstanding aerodynamics, a strong engine with a big, efficient propeller, a short and aerodynamic landing gear, as well as effective flaperons."

The carbon-spaceframe is effective, resulting in a calculated +9 and –6g ultimate load strength. "Furthermore," Jörg said, "the complete cockpit area is constructed as a Kevlar-reinforced safety cell." A ballistic parachute will further enhance safety.

In our  Not only can Corsair meet USA's Part 103, it also can qualify for Germany's 120-kilo class and Britain's Single Seat DeRegulated (SSDR) class (

Not only can Corsair meet USA's Part 103, it also can qualify for Germany's 120-kilo class and Britain's Single Seat DeRegulated (SSDR) class ( I will cover many aircraft stories, but allow me to take the most recent first: flying the brand-new Rotax 915iS and comparing it to the 912iS, although not in the same airframe. Other than official Rotax pilots and select airframe builders, we were among the first to experience the powerful new engine from the world’s leading producer of engines for light aircraft.

I will cover many aircraft stories, but allow me to take the most recent first: flying the brand-new Rotax 915iS and comparing it to the 912iS, although not in the same airframe. Other than official Rotax pilots and select airframe builders, we were among the first to experience the powerful new engine from the world’s leading producer of engines for light aircraft.

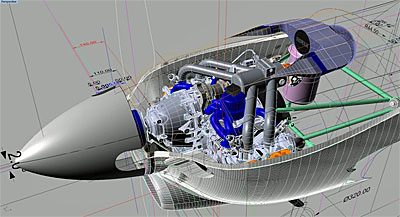

Fuel consumption was higher than I expected, but speed was also higher. To get below 3 gph, a surprisingly low consumption rate, speed dropped below 100 knots true or 85 indicated. When zipping along faster than 170 miles an hour true, consumption rose to the 7-9 gph range.

The 915iS fuel injected, turbocharged, and intercooled engine can produce 141 horsepower for five minutes, then sustain 135 horsepower indefinitely.

Once at altitude, Christian demonstrated use of the throttle and prop controls — this was not a single lever control airplane — to adjust for speed or economy. As you can see in the contrasting Stock Box images, we saw as low as 2.8 gallons per hour resulting, of course, in lower speed flight.

Fuel consumption was higher than I expected, but speed was also higher. To get below 3 gph, a surprisingly low consumption rate, speed dropped below 100 knots true or 85 indicated. When zipping along faster than 170 miles an hour true, consumption rose to the 7-9 gph range.

The 915iS fuel injected, turbocharged, and intercooled engine can produce 141 horsepower for five minutes, then sustain 135 horsepower indefinitely.

Once at altitude, Christian demonstrated use of the throttle and prop controls — this was not a single lever control airplane — to adjust for speed or economy. As you can see in the contrasting Stock Box images, we saw as low as 2.8 gallons per hour resulting, of course, in lower speed flight.

Christian demonstrated that you can move the throttle and prop control without my experience of adjusting each very cautiously and slowly. Christian jockeyed them around liberally without detriment. A key reason this is possible is because of liquid cooling versus my older experience in air-cooled legacy engines, for example, in a Cessna 182 Skylane.

A fellow aviation journalist — a pilot of 300 different aircraft — Dave Unwin felt the 915 started "softer." He also felt it seemed to run slightly smoother. Rotax engine experts felt most of this is attributable to software and the same code can also be applied to the 912iS.

Christian demonstrated that you can move the throttle and prop control without my experience of adjusting each very cautiously and slowly. Christian jockeyed them around liberally without detriment. A key reason this is possible is because of liquid cooling versus my older experience in air-cooled legacy engines, for example, in a Cessna 182 Skylane.

A fellow aviation journalist — a pilot of 300 different aircraft — Dave Unwin felt the 915 started "softer." He also felt it seemed to run slightly smoother. Rotax engine experts felt most of this is attributable to software and the same code can also be applied to the 912iS.

Yet for those who yearn for more power or are building an aircraft of higher capabilities, the 915iS is going to be a welcome powerplant. It does come with a few costs, as did the 912iS fuel injected engine compared to the 912ULS carbureted engine.

Marc Becker summarized, "The 915iS is about 12 kilos (26 pounds) more for the engine only; 40-50 more pounds when installed and about €3,000 ($3,750 at today's exchange rates) more than the 914." It is significantly more than the 912iS, as you should expect for an engine with substantially more power and the ability to use that power up to higher altitudes.

Fuel needs of both 915iS and 912iS are essentially the same. Thomas Uhr, head of Rotax's Austria plant and a longtime engine expert and enthusiast — and also a pilot — advises the highest octane auto fuel, preferably without alcohol, to get the most power and best results.

Yet for those who yearn for more power or are building an aircraft of higher capabilities, the 915iS is going to be a welcome powerplant. It does come with a few costs, as did the 912iS fuel injected engine compared to the 912ULS carbureted engine.

Marc Becker summarized, "The 915iS is about 12 kilos (26 pounds) more for the engine only; 40-50 more pounds when installed and about €3,000 ($3,750 at today's exchange rates) more than the 914." It is significantly more than the 912iS, as you should expect for an engine with substantially more power and the ability to use that power up to higher altitudes.

Fuel needs of both 915iS and 912iS are essentially the same. Thomas Uhr, head of Rotax's Austria plant and a longtime engine expert and enthusiast — and also a pilot — advises the highest octane auto fuel, preferably without alcohol, to get the most power and best results.

Immediately following

Immediately following

Igor appears to achieved his goal.

SD Planes' show aircraft at Aero 2018, its first production example, is powered by the Rotax 912 ULS2 engine, which should yield sprightly performance from this very light aircraft. SD-2 weighs in at a lean 578 pounds. Given a 1,320 maximum takeoff weight, it can carry 125% of its empty weight. Even with full fuel (26 gallons) SD-2 can carry a payload slightly greater than its empty weight. Few two seaters can match that feat. It's largely wood structure is tough enough to handle a +5/-3 g limit load.

SD-2 can run at LSA speeds of around 120 knots and stalls at a low 34 knots, very close to the 4:1 holy grail of maximum to minimum speed.

Similar to SD-1 Minisport, SD-2's fuselage employs primarily a wood truss design although the wing has a carbon main spar with composite integral fuel tank. Covered with thin (1.5 mm) plywood, SD-2 is a genuine composite aircraft. Wingtips are built of glass and PVC foam sandwich, but wood does most duty as it is low cost and proven. Big slotted flaps are made of carbon with PVC foam sandwich while counterbalanced ailerons are built of plywood and XPS foam. Wings attach to the fuselage using two main and two auxiliary pins that Spacek said allows disassembly in only 10 minutes.

Igor appears to achieved his goal.

SD Planes' show aircraft at Aero 2018, its first production example, is powered by the Rotax 912 ULS2 engine, which should yield sprightly performance from this very light aircraft. SD-2 weighs in at a lean 578 pounds. Given a 1,320 maximum takeoff weight, it can carry 125% of its empty weight. Even with full fuel (26 gallons) SD-2 can carry a payload slightly greater than its empty weight. Few two seaters can match that feat. It's largely wood structure is tough enough to handle a +5/-3 g limit load.

SD-2 can run at LSA speeds of around 120 knots and stalls at a low 34 knots, very close to the 4:1 holy grail of maximum to minimum speed.

Similar to SD-1 Minisport, SD-2's fuselage employs primarily a wood truss design although the wing has a carbon main spar with composite integral fuel tank. Covered with thin (1.5 mm) plywood, SD-2 is a genuine composite aircraft. Wingtips are built of glass and PVC foam sandwich, but wood does most duty as it is low cost and proven. Big slotted flaps are made of carbon with PVC foam sandwich while counterbalanced ailerons are built of plywood and XPS foam. Wings attach to the fuselage using two main and two auxiliary pins that Spacek said allows disassembly in only 10 minutes.

Side by seats seats are equipped with in-flight adjustable pedals with 6-inch (150 mm) range, that the designer said will accommodate someone 6.6 feet tall (200 cm) tall. Inside, SD-2 is spacious with a 46-inch (117 cm) cockpit width at the shoulders. A fairly roomy baggage compartment holds 44 pounds (20 kg) behind the seats.

To discover more about SD-2 SportMaster and to learn its cost,

Side by seats seats are equipped with in-flight adjustable pedals with 6-inch (150 mm) range, that the designer said will accommodate someone 6.6 feet tall (200 cm) tall. Inside, SD-2 is spacious with a 46-inch (117 cm) cockpit width at the shoulders. A fairly roomy baggage compartment holds 44 pounds (20 kg) behind the seats.

To discover more about SD-2 SportMaster and to learn its cost,

When most pilots think of imports, they assume a foreign manufacturer builds an aircraft in another country, finds a U.S. representative, and sends their product here. That's certainly the standard practice.

For years, especially after the fall of Communism and the opening of Eastern European nations, rates of pay for highly qualified workers was so low that building in America was considered by many to be noncompetitive. Slowly, though, the situation has changed and now American production makes more sense, at least when the company intends to sell to Yankee pilots.

At Sun 'n Fun 2018 I uncovered two new projects; one about which I had some knowledge, another that surprised me.

When most pilots think of imports, they assume a foreign manufacturer builds an aircraft in another country, finds a U.S. representative, and sends their product here. That's certainly the standard practice.

For years, especially after the fall of Communism and the opening of Eastern European nations, rates of pay for highly qualified workers was so low that building in America was considered by many to be noncompetitive. Slowly, though, the situation has changed and now American production makes more sense, at least when the company intends to sell to Yankee pilots.

At Sun 'n Fun 2018 I uncovered two new projects; one about which I had some knowledge, another that surprised me.

Sky Arrow has long been well represented by

Sky Arrow has long been well represented by  I described this experience but soon thereafter I was called to account for allegedly trampling on the rights of a Columbian designer who claimed the Serbian company had no right to produce it. At

I described this experience but soon thereafter I was called to account for allegedly trampling on the rights of a Columbian designer who claimed the Serbian company had no right to produce it. At  Initial production will be mostly done in Serbia, but as the U.S. operation gears up, raw materials such as aluminum sheet that have come from American sources will be partially prepared in the U.S., sent to Serbia for labor-intensive work by Serbians, and returned to American for final assembly and fitting of components such as avionics and engines that come from still other countries, including the USA. Though this may sound complex, it is very similar to what Boeing and Airbus do as they build airlines. It works for small companies, too.

I expect to report more on both projects — Sky Arrow and Discovery 600 — as they progress but our videos will fill in gaps in the meantime. Whatever way these projects evolve, it is interesting to see manufacturing come to American shores. Mr. Trump may be smiling, but much more important is the satisfaction of American pilots who will be given more aircraft choices.

Welcome to more of a famous label… Made in the USA.

Initial production will be mostly done in Serbia, but as the U.S. operation gears up, raw materials such as aluminum sheet that have come from American sources will be partially prepared in the U.S., sent to Serbia for labor-intensive work by Serbians, and returned to American for final assembly and fitting of components such as avionics and engines that come from still other countries, including the USA. Though this may sound complex, it is very similar to what Boeing and Airbus do as they build airlines. It works for small companies, too.

I expect to report more on both projects — Sky Arrow and Discovery 600 — as they progress but our videos will fill in gaps in the meantime. Whatever way these projects evolve, it is interesting to see manufacturing come to American shores. Mr. Trump may be smiling, but much more important is the satisfaction of American pilots who will be given more aircraft choices.

Welcome to more of a famous label… Made in the USA. On a single day of recording several videos at

On a single day of recording several videos at  Viking Aircraft Engines takes a Honda block and sets it up as an aircraft powerplant. Many homebuilders have installed them since the company reorganized in 2010. Their powerful engines have

Viking Aircraft Engines takes a Honda block and sets it up as an aircraft powerplant. Many homebuilders have installed them since the company reorganized in 2010. Their powerful engines have  He has altered the wing to be all metal with a bonded adhesion that leaves the metallic upper surface as clean as a composite wing. Fat tundra tires fitted to the show example gave the taildragger a gutsy appeal.

He has altered the wing to be all metal with a bonded adhesion that leaves the metallic upper surface as clean as a composite wing. Fat tundra tires fitted to the show example gave the taildragger a gutsy appeal.

The events triggering the long distance migration by Viking and Chipper are the Alaska Airman show in May— held in the cavernous FedEx hangar plus outside displays — plus the Valdez STOL competition.

Now in its 21st season for 2018, the

The events triggering the long distance migration by Viking and Chipper are the Alaska Airman show in May— held in the cavernous FedEx hangar plus outside displays — plus the Valdez STOL competition.

Now in its 21st season for 2018, the  One week later comes the

One week later comes the  After a damp opening day, the sun returned on day #2 at

After a damp opening day, the sun returned on day #2 at  DeLand Showcase

DeLand Showcase Overall this seems part of a surge in Part 103 interest, for plenty of good reasons: • greater freedom (no license or registration required, • no medical of any kind needed, and • the aircraft can be delivered ready-to-fly. The best news for budget-minded flying enthusiasts is truly • low prices for these single seaters that typically fly 40-55 mph. Companies like Kolb Aircraft and U-Fly-It — maker of the

Overall this seems part of a surge in Part 103 interest, for plenty of good reasons: • greater freedom (no license or registration required, • no medical of any kind needed, and • the aircraft can be delivered ready-to-fly. The best news for budget-minded flying enthusiasts is truly • low prices for these single seaters that typically fly 40-55 mph. Companies like Kolb Aircraft and U-Fly-It — maker of the  Additional changes are likely, for example:

Additional changes are likely, for example:

By the time a new AirVenture rolls around this summer — barely over three months away — Just should be ready to start deliveries to selected customers who will build kits and offer Just feedback on the aircraft. After a short period of evaluation, Just plans to offer fully-built models if the buyer selects appropriate engines and options.

As one who enjoys genuine Part 103 vehicles, I am excited to see this resurgence in aviation's lightest powered flying machines and I bet Just will sell a good many of their new entry.

Weather looks good for the next few days so come join us at Sun 'n Fun 2018. If you cannot come to Florida, stay tuned to this website for more updates (even if it does keep me up late to provide these updates). Sure, these shows make for long days but what better way to enjoy life than watching airplanes fly all day and talking to our flying buddies.

Here's a one and a half minute swing by the LSA Mall at Sun 'n Fun 2018:

https://youtu.be/mIIIaRNdcUQ

By the time a new AirVenture rolls around this summer — barely over three months away — Just should be ready to start deliveries to selected customers who will build kits and offer Just feedback on the aircraft. After a short period of evaluation, Just plans to offer fully-built models if the buyer selects appropriate engines and options.

As one who enjoys genuine Part 103 vehicles, I am excited to see this resurgence in aviation's lightest powered flying machines and I bet Just will sell a good many of their new entry.

Weather looks good for the next few days so come join us at Sun 'n Fun 2018. If you cannot come to Florida, stay tuned to this website for more updates (even if it does keep me up late to provide these updates). Sure, these shows make for long days but what better way to enjoy life than watching airplanes fly all day and talking to our flying buddies.

Here's a one and a half minute swing by the LSA Mall at Sun 'n Fun 2018:

https://youtu.be/mIIIaRNdcUQ

After

After  Pete Krotje, owner of Jabiru North America stated: “Arion Aircraft has been a Jabiru Service Center for many years. Their experience makes this a perfect fit to advance the sales of Jabiru brand power products throughout North America. I’m eagerly looking forward to the energy and creativity that Nick Otterback and Arion Aircraft will bring to the Jabiru engine fleet in North America.”

“Arion Aircraft has assumed all North American sales and marketing activities for the Jabiru Engine product line at our Shelbyville, Tennessee location at KSYI airport," said Nick Otterback, the owner of Arion. He added that all new engine and parts inquiries and orders will be directed, fulfilled and delivered through Arion Aircraft.

“This complements our existing kit and LSA aircraft manufacturing business," Nick clarified. "The majority of the nearly 200 kit and LSAs we have produced are powered by Jabiru engines giving us substantial experience with the Jabiru product line."

Pete Krotje, owner of Jabiru North America stated: “Arion Aircraft has been a Jabiru Service Center for many years. Their experience makes this a perfect fit to advance the sales of Jabiru brand power products throughout North America. I’m eagerly looking forward to the energy and creativity that Nick Otterback and Arion Aircraft will bring to the Jabiru engine fleet in North America.”

“Arion Aircraft has assumed all North American sales and marketing activities for the Jabiru Engine product line at our Shelbyville, Tennessee location at KSYI airport," said Nick Otterback, the owner of Arion. He added that all new engine and parts inquiries and orders will be directed, fulfilled and delivered through Arion Aircraft.

“This complements our existing kit and LSA aircraft manufacturing business," Nick clarified. "The majority of the nearly 200 kit and LSAs we have produced are powered by Jabiru engines giving us substantial experience with the Jabiru product line."

Nick said his enterprise will offer repair and maintenance services for Jabiru engines as well as Jabiru Aircraft from the former Jabiru North America location (located next door to Arion Aircraft). "We’re really excited about Jabiru’s new Gen IV engine and the benefits it will offer amateur builders." Pete Krotje will continue to help with Jabiru technical support as Arion adds the Jabiru engine business.

Nick did stress, however, "

Nick said his enterprise will offer repair and maintenance services for Jabiru engines as well as Jabiru Aircraft from the former Jabiru North America location (located next door to Arion Aircraft). "We’re really excited about Jabiru’s new Gen IV engine and the benefits it will offer amateur builders." Pete Krotje will continue to help with Jabiru technical support as Arion adds the Jabiru engine business.

Nick did stress, however, "

One bone of contention among LSA sellers is that legacy flight schools — the sort that typically uses Cessna or Piper trainers — sometimes disregard LSA as trainer aircraft. "They're built too lightly." "The nose wheels are too weak." "My mechanic doesn't know the Rotax engine." Some may have even more creative excuses.

I've interviewed many producers that are frustrated with this outdated response. Several have cited specific aircraft that have done flight school duty for thousands of hours and tens of thousands of landings.

Yet the ill-informed attitude of such school operators has not stopped sellers from trying. One such dogged entrepreneur is Michael Coates, the Australia-based largest dealer for Slovenian LSA producer,

One bone of contention among LSA sellers is that legacy flight schools — the sort that typically uses Cessna or Piper trainers — sometimes disregard LSA as trainer aircraft. "They're built too lightly." "The nose wheels are too weak." "My mechanic doesn't know the Rotax engine." Some may have even more creative excuses.

I've interviewed many producers that are frustrated with this outdated response. Several have cited specific aircraft that have done flight school duty for thousands of hours and tens of thousands of landings.

Yet the ill-informed attitude of such school operators has not stopped sellers from trying. One such dogged entrepreneur is Michael Coates, the Australia-based largest dealer for Slovenian LSA producer,  He referenced an order for 15 Pipistrel Alpha Trainer aircraft with instrumentation configured for IFR training (photo) ordered for delivery to San Bernardino, California.

He referenced an order for 15 Pipistrel Alpha Trainer aircraft with instrumentation configured for IFR training (photo) ordered for delivery to San Bernardino, California.

WWW considered SportCruiser, Tecnam, Skycatcher, Flight Design, Evektor, Pipistrel and a few others. "We leased and put some of these airplanes to work in our training environment,"

"This provided a very good understanding of their suitability in terms of safety, performance(s), maintenance, handling, durability, serviceability and up times," the school indicated. "Feedback from students was also very helpful."

Earlier, the Pipistrel factory sold 200 Alpha Trainers to the Indian military. "Their feedback on the aircraft durability was a consideration," observed WWW. Another factory affective the sales was a report of a Pipistrel Alpha Trainer in New Caledonia that recently surpassed 4,000 hours of training in a challenging tropical/marine environment; the aircraft has not reported problems.

Deliveries from Pipistrel's Italy production facility will start later this month, with delivery and commissioning in San Bernardino scheduled for the first week of June, 2018.

More than 300 Pipistrel Alpha Trainers have been produced and are flying in 35 countries including almost 50 in the USA alone, reported Coates.

WWW considered SportCruiser, Tecnam, Skycatcher, Flight Design, Evektor, Pipistrel and a few others. "We leased and put some of these airplanes to work in our training environment,"

"This provided a very good understanding of their suitability in terms of safety, performance(s), maintenance, handling, durability, serviceability and up times," the school indicated. "Feedback from students was also very helpful."

Earlier, the Pipistrel factory sold 200 Alpha Trainers to the Indian military. "Their feedback on the aircraft durability was a consideration," observed WWW. Another factory affective the sales was a report of a Pipistrel Alpha Trainer in New Caledonia that recently surpassed 4,000 hours of training in a challenging tropical/marine environment; the aircraft has not reported problems.

Deliveries from Pipistrel's Italy production facility will start later this month, with delivery and commissioning in San Bernardino scheduled for the first week of June, 2018.

More than 300 Pipistrel Alpha Trainers have been produced and are flying in 35 countries including almost 50 in the USA alone, reported Coates.

This Shark is one I've long admired since meeting its creator, Jaro Dostal many years ago at the German airshow

This Shark is one I've long admired since meeting its creator, Jaro Dostal many years ago at the German airshow  A special "Mako" Shark is now available, reported an enthusiastic Jon. "The Rotax 915-powered Shark will enhance high altitude performance, increase cruising speed, and rate of climb" he said. "The first prototype is expected to be completed this summer." The factory is now taking orders. The nearby images show new, larger cowlings to accommodate a turbocharged, intercooler-equipped 135 horsepower engine.

If you are enticed, here are two ways to acquire Shark.

Order a new aircraft — "The factory will now take €4,000 (about $5,000 but this can change) non-refundable or €15,000 (about $19,000) refundable deposit to hold a production slot. Upon receiving the deposit, the factory will assign a production slot and an expected delivery date. Progress payments will be requested at various intervals.

A special "Mako" Shark is now available, reported an enthusiastic Jon. "The Rotax 915-powered Shark will enhance high altitude performance, increase cruising speed, and rate of climb" he said. "The first prototype is expected to be completed this summer." The factory is now taking orders. The nearby images show new, larger cowlings to accommodate a turbocharged, intercooler-equipped 135 horsepower engine.

If you are enticed, here are two ways to acquire Shark.

Order a new aircraft — "The factory will now take €4,000 (about $5,000 but this can change) non-refundable or €15,000 (about $19,000) refundable deposit to hold a production slot. Upon receiving the deposit, the factory will assign a production slot and an expected delivery date. Progress payments will be requested at various intervals.

"The current factory backlog is between 18-24 months for a ready-to-fly aircraft or approximately 5-6 months for a kit," wrote Jon. However, he added, "With the factory ramping up to three from one aircraft per month, the wait is expected to decrease."

If you want the current final price and options list, contact Jon via email (see below).

If you can't handle the long wait or don't want to send chunks of money overseas, another way exists to own a Shark and no building is required.

"Shark UL 025, our current demonstrator aircraft, is up for sale," wrote Jon. "It is ready for delivery in April 2018 and has all the options, has been superbly cared for and is fully up to date with the latest features." How much? "We are asking €150,000 (about $188,000) plus delivery charges. Please contact me (via

"The current factory backlog is between 18-24 months for a ready-to-fly aircraft or approximately 5-6 months for a kit," wrote Jon. However, he added, "With the factory ramping up to three from one aircraft per month, the wait is expected to decrease."

If you want the current final price and options list, contact Jon via email (see below).

If you can't handle the long wait or don't want to send chunks of money overseas, another way exists to own a Shark and no building is required.

"Shark UL 025, our current demonstrator aircraft, is up for sale," wrote Jon. "It is ready for delivery in April 2018 and has all the options, has been superbly cared for and is fully up to date with the latest features." How much? "We are asking €150,000 (about $188,000) plus delivery charges. Please contact me (via