I believe you should applaud Milan Bristela. Now a veteran of the Light-Sport Aircraft sector, he has steadily built a successful aircraft manufacturing enterprise — BRM Aero — that recently rolled out Bristell #300. With its first delivery to a customer in 2011, this represents an average pace of 50 aircraft per year, a wonderful business size for a LSA manufacturer. Every company starts smaller and grows, so assuming a spooling up of their production engine, BRM is now completing between one and two aircraft per week. Good job, Milan and team! BRM Aero started in 2009 with two employees. Over the course of several years the team has grown to 50 employees, they report. When growth demanded, they moved into larger quarters but they’ve also maintained a family feel with father Milan and son Martin running the enterprise as partners. The full name of their very handsome aircraft is Bristell NG 5 LSA.

I believe you should applaud Milan Bristela. Now a veteran of the Light-Sport Aircraft sector, he has steadily built a successful aircraft manufacturing enterprise —

I believe you should applaud Milan Bristela. Now a veteran of the Light-Sport Aircraft sector, he has steadily built a successful aircraft manufacturing enterprise —  Back in 2003, when I was still involved with BRS Parachutes, I traveled to the Czech Republic. My contact was American Chip Erwin, then head of Czech Aircraft Works and now the man behind

Back in 2003, when I was still involved with BRS Parachutes, I traveled to the Czech Republic. My contact was American Chip Erwin, then head of Czech Aircraft Works and now the man behind  In the USA, Bristell now enjoys a highly experienced and dedicated team at

In the USA, Bristell now enjoys a highly experienced and dedicated team at

FX1's cabin is fully enclosed and sports large, curved doors. The tail is joined by a more conventional looking fuselage rather than a simple tailboom. The engine is now fully enclosed. Flightstar built it the way they did for some 1,000 aircraft to keep the weight down to a minimum because of the ultralight regulations of the day. That was also a simpler time and today's FX1 may have appeared bulky and expensive back in the early 2000s.

After bringing in the aircraft of other producers Alfredo began work on his own design resulting in the JetFox 91 (in 1991), followed by an upgraded model called JetFox 97, and finally the JetFox GT in 2005. That was about the time Light-Sport Aircraft burst on the scene and caused pilots to look in new directions bringing doubt about the future of JetFox.

A dozen years later, Alfredo is back with his best looking project yet, called FX1, a fourth-generation sport plane evolved from multiple European sport planes over the last three decades. "This modern computer-aided design has been carefully engineered to optimize all aspects of a proven configuration," said Di Cesare (see sidebar). "It incorporates countless improvements and refinements that came from the knowledge and experience of working with similar designs."

FX1's cabin is fully enclosed and sports large, curved doors. The tail is joined by a more conventional looking fuselage rather than a simple tailboom. The engine is now fully enclosed. Flightstar built it the way they did for some 1,000 aircraft to keep the weight down to a minimum because of the ultralight regulations of the day. That was also a simpler time and today's FX1 may have appeared bulky and expensive back in the early 2000s.

After bringing in the aircraft of other producers Alfredo began work on his own design resulting in the JetFox 91 (in 1991), followed by an upgraded model called JetFox 97, and finally the JetFox GT in 2005. That was about the time Light-Sport Aircraft burst on the scene and caused pilots to look in new directions bringing doubt about the future of JetFox.

A dozen years later, Alfredo is back with his best looking project yet, called FX1, a fourth-generation sport plane evolved from multiple European sport planes over the last three decades. "This modern computer-aided design has been carefully engineered to optimize all aspects of a proven configuration," said Di Cesare (see sidebar). "It incorporates countless improvements and refinements that came from the knowledge and experience of working with similar designs."

Given a fresh design with Italian styling and the promise of future sales, InnovAviation announced several developments.

"We've got financial support to ramp up our serial production," said the company. They plan to demonstrate Special LSA compliance and will seek FAA acceptance "within 2017."

Their first sale went to their dealer in Israel and they noted, "We are in negotiations for dealerships in France, Scandinavia, Australia, and Iran."

For U.S. consumption, "We are in negotiations with a group of investors from Florida in order to establish a US sales and assembly point."

"We've people coming to our factory for demo flights every month," added Alfredo.

Looking for more? Contact Alfredo via

Given a fresh design with Italian styling and the promise of future sales, InnovAviation announced several developments.

"We've got financial support to ramp up our serial production," said the company. They plan to demonstrate Special LSA compliance and will seek FAA acceptance "within 2017."

Their first sale went to their dealer in Israel and they noted, "We are in negotiations for dealerships in France, Scandinavia, Australia, and Iran."

For U.S. consumption, "We are in negotiations with a group of investors from Florida in order to establish a US sales and assembly point."

"We've people coming to our factory for demo flights every month," added Alfredo.

Looking for more? Contact Alfredo via  Improved forward visibility — to enhance flying enjoyment and safety.

Improved forward visibility — to enhance flying enjoyment and safety. In this pre-Eclipse weekend post, I'll show you some images of cool flying things I saw at the big event.

Starting off with my fascination about spaceflight, EAA communications guru Dick Knapinski told of the challenges of arranging an 80-foot-tall flying machine on the central Boeing Plaza square. This is where you see a changing kaleidoscope of aircraft from old to new and slow to fast. However, no aircraft I've ever seen in this location flies as fast, stands as tall, or is more unique than the

In this pre-Eclipse weekend post, I'll show you some images of cool flying things I saw at the big event.

Starting off with my fascination about spaceflight, EAA communications guru Dick Knapinski told of the challenges of arranging an 80-foot-tall flying machine on the central Boeing Plaza square. This is where you see a changing kaleidoscope of aircraft from old to new and slow to fast. However, no aircraft I've ever seen in this location flies as fast, stands as tall, or is more unique than the  Nearby, from one of light aviation lightest aircraft sellers — Michael LeMaire and his

Nearby, from one of light aviation lightest aircraft sellers — Michael LeMaire and his  Machines like Stratos aren't what we usually cover here — any more than space rockets — but since it was beautiful to behold and is coming from one of our LSA suppliers and supporters, I enjoyed a look-see and thought you might as well.

On the way to the Ultralight Area — rebadged as the Fun Fly Zone (an accurate name, IMHO) — we passed by the antique airplane area with its own red barn, seen in the background of the nearby image. What caught my attention was the snazzy paint job or decal on this taildragger.

It doesn't compare to the superlative

Machines like Stratos aren't what we usually cover here — any more than space rockets — but since it was beautiful to behold and is coming from one of our LSA suppliers and supporters, I enjoyed a look-see and thought you might as well.

On the way to the Ultralight Area — rebadged as the Fun Fly Zone (an accurate name, IMHO) — we passed by the antique airplane area with its own red barn, seen in the background of the nearby image. What caught my attention was the snazzy paint job or decal on this taildragger.

It doesn't compare to the superlative  Finally, we arrived in arguably my favorite area of

Finally, we arrived in arguably my favorite area of  "Coming to America" is a common refrain from light aircraft producers in some countries. Why? The obvious reason is that most designers perceive a huge market in the USA. Another is that shipping from the USA to other countries proves easier than shipping from their home countries. Other reasons also exist but those two are enough to decide in favor of the move.

One builder of a LSA seaplane is

"Coming to America" is a common refrain from light aircraft producers in some countries. Why? The obvious reason is that most designers perceive a huge market in the USA. Another is that shipping from the USA to other countries proves easier than shipping from their home countries. Other reasons also exist but those two are enough to decide in favor of the move.

One builder of a LSA seaplane is  "Atol's cockpit is totally newly designed and looks great," added Anssi. The long established tradition in aviation (and most industries) of adapting the good ideas of other designers shows in Atol's new MVP-like approach.

Anssi explained, "Atol's new articulating canopy retracts up and back, getting out of the way, allowing pilot and passenger to stand upright and access the cockpit from the front if desired, which makes docking and beaching easy. Our avionics retract with the canopy allowing them to be out of harm’s way, avoiding water spray. The seats are removable so when operating solo you can load up with gear to take advantage of our industry leading 600 pound useful load. Carbon fiber is accented with beautifully finished wood trim providing the feel of a classic automobile… it truly is striking."

"Atol's cockpit is totally newly designed and looks great," added Anssi. The long established tradition in aviation (and most industries) of adapting the good ideas of other designers shows in Atol's new MVP-like approach.

Anssi explained, "Atol's new articulating canopy retracts up and back, getting out of the way, allowing pilot and passenger to stand upright and access the cockpit from the front if desired, which makes docking and beaching easy. Our avionics retract with the canopy allowing them to be out of harm’s way, avoiding water spray. The seats are removable so when operating solo you can load up with gear to take advantage of our industry leading 600 pound useful load. Carbon fiber is accented with beautifully finished wood trim providing the feel of a classic automobile… it truly is striking."

Among LSA seaplanes a 600 pound useful load is also striking. Anssi explains how they achieve that, "The outer layer of our hull is Kevlar with cold-molded, foam-cored birch. This combination is extremely rugged, light and strong. We use fabric covered wings featuring Oratex. These can be lighter than carbon fiber with the added benefit of field repairable. This is a real plus for a seaplane."

“Finland has 188,000 lakes," said Anssi, "so we know the joys of water flying as well as the demands. Many of these lakes are remote and require range and reliability to access so we designed the Atol 650 for this environment.” Atol's 650 designation refers to 650 kilograms, the metric equivalent of FAA's 1,430 pound seaplane weight limit.

Among LSA seaplanes a 600 pound useful load is also striking. Anssi explains how they achieve that, "The outer layer of our hull is Kevlar with cold-molded, foam-cored birch. This combination is extremely rugged, light and strong. We use fabric covered wings featuring Oratex. These can be lighter than carbon fiber with the added benefit of field repairable. This is a real plus for a seaplane."

“Finland has 188,000 lakes," said Anssi, "so we know the joys of water flying as well as the demands. Many of these lakes are remote and require range and reliability to access so we designed the Atol 650 for this environment.” Atol's 650 designation refers to 650 kilograms, the metric equivalent of FAA's 1,430 pound seaplane weight limit.

"We think Atol USA is the best and fastest solution for us to be able to serve our North American customers. Our Rovaniemi factory in Finland (photo) will produce for the rest of the world and continue product development,” Anssi added.

Atol USA will produce the 650 at Brunswick Executive Airport (KBXM), site of the former Brunswick Naval Air Station. A local development authority has created a manufacturing technology incubator and is "currently constructing an environmentally-controlled composites layup room, curing oven and paint booth designed to aviation standards and sized to accept wings, fuselages and other large structures. These complement our CNC machining center, welding shops, 3D printers and on-site Composites Engineering Research Lab," said development director Steve Levesque. "We make these assets available to companies throughout the State of Maine." The northeastern state has a long history with amphibious flight having been the home to Lake Aircraft for decades.

"We think Atol USA is the best and fastest solution for us to be able to serve our North American customers. Our Rovaniemi factory in Finland (photo) will produce for the rest of the world and continue product development,” Anssi added.

Atol USA will produce the 650 at Brunswick Executive Airport (KBXM), site of the former Brunswick Naval Air Station. A local development authority has created a manufacturing technology incubator and is "currently constructing an environmentally-controlled composites layup room, curing oven and paint booth designed to aviation standards and sized to accept wings, fuselages and other large structures. These complement our CNC machining center, welding shops, 3D printers and on-site Composites Engineering Research Lab," said development director Steve Levesque. "We make these assets available to companies throughout the State of Maine." The northeastern state has a long history with amphibious flight having been the home to Lake Aircraft for decades.

We expect to deliver these airframes beginning in the first quarter of 2019 and at a firm fixed price. What price? "Current pricing is $179,000 for delivery through 2018, although most of these positions are allocated so our open slots begin in 2019," explained Paul.

Want to know more? Review Atol's technical specifications

We expect to deliver these airframes beginning in the first quarter of 2019 and at a firm fixed price. What price? "Current pricing is $179,000 for delivery through 2018, although most of these positions are allocated so our open slots begin in 2019," explained Paul.

Want to know more? Review Atol's technical specifications

His first production aircraft weighed in at 242 pounds. Sound familiar? Maybe that's where FAA conjured the 254 pound empty weight of Part 103 aircraft, a category created 76 years later, in 1982.

On January 4th, 1910, Santos Dumont broke a flying wire and crashed. He never flew again. History doesn't record if his mishap was in a 19 Bis, or the 20, 21, or 22.

The Winchester Skonkwerks Ultralight Research and Development Facility — let's shorten that to Skonkwerks — represents a team from Larsen, Wisconsin. Skonkwerks honored Alberto by first building a 23 Bis and later the 24 Bis you see in nearby images taken at AirVenture Oshkosh 2017. The group describes itself as a "loosely knit organization of friends, flyers, and fanatics… tinkerers, builders, and bullsh###rs. We are engineers, designers, and dreamers hanging out in a little hangar screwing stuff together and making it fly."

His first production aircraft weighed in at 242 pounds. Sound familiar? Maybe that's where FAA conjured the 254 pound empty weight of Part 103 aircraft, a category created 76 years later, in 1982.

On January 4th, 1910, Santos Dumont broke a flying wire and crashed. He never flew again. History doesn't record if his mishap was in a 19 Bis, or the 20, 21, or 22.

The Winchester Skonkwerks Ultralight Research and Development Facility — let's shorten that to Skonkwerks — represents a team from Larsen, Wisconsin. Skonkwerks honored Alberto by first building a 23 Bis and later the 24 Bis you see in nearby images taken at AirVenture Oshkosh 2017. The group describes itself as a "loosely knit organization of friends, flyers, and fanatics… tinkerers, builders, and bullsh###rs. We are engineers, designers, and dreamers hanging out in a little hangar screwing stuff together and making it fly."

Skonkwerks is an honoring nod to the famed Lockheed Martin Skunkworks, the latter becoming a term widely used in a generic sense to denote a group within an organization given a high degree of autonomy to work on advanced, sometimes secret projects. The Winchester Skonkwerks uses the name "in jest to project an aura of something outside of the norm being worked on, developed, or flown while staying in touch with meager roots."

With this article you see no website or phone numbers. This aircraft is not for sale but is certainly worthy of you traipsing down to Oshkosh's Fun Fly Zone (i.e., the Ultralight Area) to see for yourself.

Meanwhile, here's a few facts you might enjoy:

Skonkwerks is an honoring nod to the famed Lockheed Martin Skunkworks, the latter becoming a term widely used in a generic sense to denote a group within an organization given a high degree of autonomy to work on advanced, sometimes secret projects. The Winchester Skonkwerks uses the name "in jest to project an aura of something outside of the norm being worked on, developed, or flown while staying in touch with meager roots."

With this article you see no website or phone numbers. This aircraft is not for sale but is certainly worthy of you traipsing down to Oshkosh's Fun Fly Zone (i.e., the Ultralight Area) to see for yourself.

Meanwhile, here's a few facts you might enjoy:

This is the

This is the

The latter comparison is especially apt because this is one of those airplanes you get on rather than in. Pilots side astride the welded steel forward fuselage with their feet on the rudder pedals out in the breeze, although at a top allowed speed of 63 mph (55 knots), that breeze won't be particularly windy.

Troy indicated they have done all the analysis and much of the testing (wings are done even though they weren't brought to Oshkosh). He is sure it will make the empty weight challenge of 254 pounds.

Before it even flies, no price has been set, but with an engine price well under $4,000 and a simple airframe from a very established builder, it is reasonable to think Just 103 will be quite affordable. Stay tuned!

* I did not write Part 103 vehicles are the lightest powered aircraft as Part 103 also covers hang gliders and paraglider, which are commonly unpowered.

The latter comparison is especially apt because this is one of those airplanes you get on rather than in. Pilots side astride the welded steel forward fuselage with their feet on the rudder pedals out in the breeze, although at a top allowed speed of 63 mph (55 knots), that breeze won't be particularly windy.

Troy indicated they have done all the analysis and much of the testing (wings are done even though they weren't brought to Oshkosh). He is sure it will make the empty weight challenge of 254 pounds.

Before it even flies, no price has been set, but with an engine price well under $4,000 and a simple airframe from a very established builder, it is reasonable to think Just 103 will be quite affordable. Stay tuned!

* I did not write Part 103 vehicles are the lightest powered aircraft as Part 103 also covers hang gliders and paraglider, which are commonly unpowered. After more than a year, a resolution was reached for the airplane that topped the charts in the LSA space since Day One. Although Flight Design's CT-series was

After more than a year, a resolution was reached for the airplane that topped the charts in the LSA space since Day One. Although Flight Design's CT-series was  Tom explained, "The new company will be known as Flight Design General Aviation, GmbH. After concluding the sale of all major company assets to the Lift Holding investment group, Flight Design General Aviation will be based at a new and modern facility (photo) near the historic town of Eisenach in the Thuringia region of Germany.

Tom explained, "The new company will be known as Flight Design General Aviation, GmbH. After concluding the sale of all major company assets to the Lift Holding investment group, Flight Design General Aviation will be based at a new and modern facility (photo) near the historic town of Eisenach in the Thuringia region of Germany. Lift is also the owner of the

Lift is also the owner of the  FDGA has aircraft operating in 48 countries around the globe. The company will soon employ 20 employees in Germany — mostly highly qualified engineers and technicians — as well as about 100 manufacturing employees in Ukraine. Since the founding of the company in 1988 and the establishment of the Ukrainian production plant in 1993, the company has delivered over 1,800 aircraft.

"Flight Design has some unique products and experience in the production of all carbon-composite, very efficient light aircraft. We want to invest in development of those products and also achieve leadership in customer support," said Lars Joerges, the new Managing Director of FDGA.

Flight Design General Aviation also plans to continue development of the C4 four-place aircraft, although Tom Peghiny said the program would change to accommodate the efficiencies in a changing certification landscape in the United States and abroad, referring to the long-awaited Part 23 rewrite and its mirror regulation in Europe.

Tom indicated that FDGA will make a return to AirVenture for the 2018 event.

FDGA has aircraft operating in 48 countries around the globe. The company will soon employ 20 employees in Germany — mostly highly qualified engineers and technicians — as well as about 100 manufacturing employees in Ukraine. Since the founding of the company in 1988 and the establishment of the Ukrainian production plant in 1993, the company has delivered over 1,800 aircraft.

"Flight Design has some unique products and experience in the production of all carbon-composite, very efficient light aircraft. We want to invest in development of those products and also achieve leadership in customer support," said Lars Joerges, the new Managing Director of FDGA.

Flight Design General Aviation also plans to continue development of the C4 four-place aircraft, although Tom Peghiny said the program would change to accommodate the efficiencies in a changing certification landscape in the United States and abroad, referring to the long-awaited Part 23 rewrite and its mirror regulation in Europe.

Tom indicated that FDGA will make a return to AirVenture for the 2018 event.

"We received confirmation from EAA on the time slot for our forum and meet & greet at

"We received confirmation from EAA on the time slot for our forum and meet & greet at

The only light aircraft producer based right at the home field of

The only light aircraft producer based right at the home field of  Sonex will also present the tricycle gear version of the new B-model Sonex for the first time. The B-models now include the Sonex, Waiex, and Xenos motorglider models but to-date all have been taildraggers. If that's not your experience, Sonex now has you covered with tricycle gear.

After hearing from customers, the company has also created a mount system to accommodate the very popular

Sonex will also present the tricycle gear version of the new B-model Sonex for the first time. The B-models now include the Sonex, Waiex, and Xenos motorglider models but to-date all have been taildraggers. If that's not your experience, Sonex now has you covered with tricycle gear.

After hearing from customers, the company has also created a mount system to accommodate the very popular  Even though Sonex employees are doing double duty during AirVenture, the company conducts daily factory tours during the event. However, if you aren't going to Oshkosh or don't want to tear yourself away from the show, you can catch our

Even though Sonex employees are doing double duty during AirVenture, the company conducts daily factory tours during the event. However, if you aren't going to Oshkosh or don't want to tear yourself away from the show, you can catch our  One of the stalwarts of the light aircraft sector is Kitfox, a brand known widely around the globe. First flown in November 1984 by Dan Denney, nearly 5,000 aircraft in various models have been produced. Nearly all were built from kits but the company also achieved

One of the stalwarts of the light aircraft sector is Kitfox, a brand known widely around the globe. First flown in November 1984 by Dan Denney, nearly 5,000 aircraft in various models have been produced. Nearly all were built from kits but the company also achieved  Using the fuel injected

Using the fuel injected

Some Dragonfly pilots working at the Ranch have more than 10,000 hours logged in Dragonflys alone. All that is achieved in an intense, full-power flight towing a hang gliding on a 200 or so foot line to 2,500 feet then releasing the glider, abruptly powering back to idle thrust, and diving madly for the ground to snatch another waiting pilot into the air. A round-trip takes literally minutes so think about how many takeoffs and landings were involved for a pilot to log 10,000 hours doing so.

During some competition events, I have seen 11 Dragonflys doing this drill. It is nearly mind-blowing to watch a collection of these awkward-looking aerial tractors whizzing this way and that in an utterly chaotic-looking yet amazingly well-choreographed ballet of tow planes and glider pilots. You literally have to see it to belief it. My words to describe it pale in comparison.

Some Dragonfly pilots working at the Ranch have more than 10,000 hours logged in Dragonflys alone. All that is achieved in an intense, full-power flight towing a hang gliding on a 200 or so foot line to 2,500 feet then releasing the glider, abruptly powering back to idle thrust, and diving madly for the ground to snatch another waiting pilot into the air. A round-trip takes literally minutes so think about how many takeoffs and landings were involved for a pilot to log 10,000 hours doing so.

During some competition events, I have seen 11 Dragonflys doing this drill. It is nearly mind-blowing to watch a collection of these awkward-looking aerial tractors whizzing this way and that in an utterly chaotic-looking yet amazingly well-choreographed ballet of tow planes and glider pilots. You literally have to see it to belief it. My words to describe it pale in comparison.

What else might it do? Well, plenty perhaps, and especially so should FAA allow LAMA to coordinate with industry for a test period to see if Light-Sport Aircraft can become working aircraft. More on that another time.

Ed Pitman, a longtime hang glider pilot turned aircraft manufacturer, recently gained approval for a Dragonfly Rancher model as a Special LSA. "Got both 900 & 582 series Dragonfly Ranchers approved SLSA yesterday," he wrote, taking after Bobby in being frugal with words. I pried a few more from him.

"We reworked the

What else might it do? Well, plenty perhaps, and especially so should FAA allow LAMA to coordinate with industry for a test period to see if Light-Sport Aircraft can become working aircraft. More on that another time.

Ed Pitman, a longtime hang glider pilot turned aircraft manufacturer, recently gained approval for a Dragonfly Rancher model as a Special LSA. "Got both 900 & 582 series Dragonfly Ranchers approved SLSA yesterday," he wrote, taking after Bobby in being frugal with words. I pried a few more from him.

"We reworked the  Every U.S. state is different when it comes to aerial application, said Ed. "Here in California, a land owner is allowed to spray their own property from the air with a standard Applicators Permit. Dragonfly Rancher is a bonafide piece of farm and ranch equipment."

"Vne on Dragonfly was 66 mph (upped from those earlier models) and Rancher goes further, to 88 mph Vne." The newly beefed-up Dragonfly can carry enough payload to do micro spraying, which — if you don't know as I did not — is a legitimate method of application in some situations.

"We increased the gross weight to 1,200 pounds because we will be putting it on floats, also," said Ed. "Bobby re-schemed the wings, which only gained 2.2 pounds each to get to that higher gross weight." The all-up weight went from 992 pounds (450 kg) earlier.

Every U.S. state is different when it comes to aerial application, said Ed. "Here in California, a land owner is allowed to spray their own property from the air with a standard Applicators Permit. Dragonfly Rancher is a bonafide piece of farm and ranch equipment."

"Vne on Dragonfly was 66 mph (upped from those earlier models) and Rancher goes further, to 88 mph Vne." The newly beefed-up Dragonfly can carry enough payload to do micro spraying, which — if you don't know as I did not — is a legitimate method of application in some situations.

"We increased the gross weight to 1,200 pounds because we will be putting it on floats, also," said Ed. "Bobby re-schemed the wings, which only gained 2.2 pounds each to get to that higher gross weight." The all-up weight went from 992 pounds (450 kg) earlier.

I asked Ed to explain what they did to bump gross and Vne speed. "We reduced rudder pressure, added electric flaperons, reinforced the main gear, and improved longitudinal stability of the Dragonfly," he clarified. A nose cone and windscreen reduces fatigue for a working pilot. Yet Dragonfly remains "fun to fly," he asured. "It actually performs better with flaps up in aerobatics — spins and loops — and still does a controllable spin."

"With floats it can be used for Introductory Flights as a SLSA," added Ed. Training pilots for towing required a second seat, though it is commonly, and easily, removed along with the aft joystick and pedals.

Interested in micro spraying? "My website has tax calculator link to see federal tax benefits," reported Ed. (calculator is another website) Also some videos.

Get more info on this hard-working aircraft on

I asked Ed to explain what they did to bump gross and Vne speed. "We reduced rudder pressure, added electric flaperons, reinforced the main gear, and improved longitudinal stability of the Dragonfly," he clarified. A nose cone and windscreen reduces fatigue for a working pilot. Yet Dragonfly remains "fun to fly," he asured. "It actually performs better with flaps up in aerobatics — spins and loops — and still does a controllable spin."

"With floats it can be used for Introductory Flights as a SLSA," added Ed. Training pilots for towing required a second seat, though it is commonly, and easily, removed along with the aft joystick and pedals.

Interested in micro spraying? "My website has tax calculator link to see federal tax benefits," reported Ed. (calculator is another website) Also some videos.

Get more info on this hard-working aircraft on  I readily admit I find

I readily admit I find  "My wife, Kathy, and I live in Chautauqua County in western New York. I've flown a converted Piper Colt out of a small grass strip airport (D79) at the end of Chautauqua Lake since 2004. After a few years , I thought I would like something a little 'zippier.'

"In 2008 I came across the Lightning at Oshkosh. I loved the look and specs for being a Light-Sport. I spoke with company boss and designer, Nick Otterback, and asked about the possibility of a tail wheel version. He thought that might be a possibility down the road.

"I saw Nick again the next year but still no tail wheel. However, I did schedule a demo ride. I was sold and bought my kit."

About this project, Nick wrote,

"My wife, Kathy, and I live in Chautauqua County in western New York. I've flown a converted Piper Colt out of a small grass strip airport (D79) at the end of Chautauqua Lake since 2004. After a few years , I thought I would like something a little 'zippier.'

"In 2008 I came across the Lightning at Oshkosh. I loved the look and specs for being a Light-Sport. I spoke with company boss and designer, Nick Otterback, and asked about the possibility of a tail wheel version. He thought that might be a possibility down the road.

"I saw Nick again the next year but still no tail wheel. However, I did schedule a demo ride. I was sold and bought my kit."

About this project, Nick wrote,  "While in construction, I decided I would commit to the tail wheel conversion. At the same time, just to see if it could be done, I decided to modify Lightning's controls to create center stick, another thing the factory had not done. I thought this would make entry easier and also let my wife have her own uncluttered space. This was my first project and at the rate I was going, I figured I wasn't going be doing too many of these so I wanted to do this one exactly how I wanted it.

"I contacted Nick and got some better clarity on center of gravity and possible wheel positions and applied them to Pazmany's formulas until everything came in within the guidelines. Theoretical weight and balance and prop clearance were also considerations. I am a retired machinist, so the metal work and fixturing was very familiar to me although I did have to 'tune' up my welding for about a year and a half before I attempted the landing gear legs and supports.

"While in construction, I decided I would commit to the tail wheel conversion. At the same time, just to see if it could be done, I decided to modify Lightning's controls to create center stick, another thing the factory had not done. I thought this would make entry easier and also let my wife have her own uncluttered space. This was my first project and at the rate I was going, I figured I wasn't going be doing too many of these so I wanted to do this one exactly how I wanted it.

"I contacted Nick and got some better clarity on center of gravity and possible wheel positions and applied them to Pazmany's formulas until everything came in within the guidelines. Theoretical weight and balance and prop clearance were also considerations. I am a retired machinist, so the metal work and fixturing was very familiar to me although I did have to 'tune' up my welding for about a year and a half before I attempted the landing gear legs and supports.

"At this time I've got about 2,500 hours into it. Although the empty CG moved a little more than an inch aft with the tail wheel, we are still well within the envelope and Light-Sport limit with two people and 20 gallons of fuel.

"I'm using the Jabiru 3300 and without the nose wheel, I hope to add a few miles an hour in cruise and lose a couple on landing."

Wisely, Mike hasn't decided if he'll do the test flight on his Lightning TD. "I've spent more time building than flying lately," Mike admitted. This is a common, smart move… to let a person other than the builder do the test flight.

Mike continued, "Buzz Rich, who is very involved with Nick at Lightning and has a ton of time in the Lightning and tail wheels, has offered to do the first flights and it would be a kick to get his take on my project if we can work it out. I'll be flying amateur built but Lightning TD will come within Light-Sport limits.

"At this time I've got about 2,500 hours into it. Although the empty CG moved a little more than an inch aft with the tail wheel, we are still well within the envelope and Light-Sport limit with two people and 20 gallons of fuel.

"I'm using the Jabiru 3300 and without the nose wheel, I hope to add a few miles an hour in cruise and lose a couple on landing."

Wisely, Mike hasn't decided if he'll do the test flight on his Lightning TD. "I've spent more time building than flying lately," Mike admitted. This is a common, smart move… to let a person other than the builder do the test flight.

Mike continued, "Buzz Rich, who is very involved with Nick at Lightning and has a ton of time in the Lightning and tail wheels, has offered to do the first flights and it would be a kick to get his take on my project if we can work it out. I'll be flying amateur built but Lightning TD will come within Light-Sport limits.

"This is way more plane than I could have ever imagined for myself."

Make is both clever with technical skills and is diplomatic as he added an essential thank-you note.

"Thanks to my wife Kathy for the great seats she sewed, for helping me move, lift, hold, and generally assist in the barn and for tolerating airplane parts in rooms around the house for seven years now. In fact, I think she misses the propeller not being in the living room anymore."

Mike also added thanks to Nick, Mark, and Buzz at Arion Aircraft.

So, now that you know Mike's story, what will you do this weekend?

"This is way more plane than I could have ever imagined for myself."

Make is both clever with technical skills and is diplomatic as he added an essential thank-you note.

"Thanks to my wife Kathy for the great seats she sewed, for helping me move, lift, hold, and generally assist in the barn and for tolerating airplane parts in rooms around the house for seven years now. In fact, I think she misses the propeller not being in the living room anymore."

Mike also added thanks to Nick, Mark, and Buzz at Arion Aircraft.

So, now that you know Mike's story, what will you do this weekend? When summer rolls around and the sweat rolls off, it's a perfect time to think about float flying. In the Light-Sport Aircraft or light kit-built airplane space, you are lucky to have a broad number of choices. This includes seaplanes (with boat hulls), floatplanes (land planes equipped with floats) or either of those on aircraft such as weight-shift trikes.

Legend Cub is a modernized version of the old Piper Cub. Sulphur Springs, Texas-based Legend was an early entrant to the LSA world. They've done well enough under the leadership of Darin Hart to occupy the #5 spot on our all-time-fleet ranking of Special LSA; they are one of only five LSA producers with more than 200 aircraft registered with FAA.

When summer rolls around and the sweat rolls off, it's a perfect time to think about float flying. In the Light-Sport Aircraft or light kit-built airplane space, you are lucky to have a broad number of choices. This includes seaplanes (with boat hulls), floatplanes (land planes equipped with floats) or either of those on aircraft such as weight-shift trikes.

Legend Cub is a modernized version of the old Piper Cub. Sulphur Springs, Texas-based Legend was an early entrant to the LSA world. They've done well enough under the leadership of Darin Hart to occupy the #5 spot on our all-time-fleet ranking of Special LSA; they are one of only five LSA producers with more than 200 aircraft registered with FAA.

Legend's floatplane offering boasts advantages. "It weighs less than comparable aircraft, cost less, and came with the added advantage of doors and windows on both sides of the cockpit," observed the company. This design feature — not present on the original Piper models — is especially appropriate for float-equipped aircraft, offering egress from either side while docking.

Legend FloatCub comes standard with dual entry doors and windows, dual wing tanks, a larger cabin, and electric start (also not on Piper's iconic original). "You have a choice of engines, including the 100-horsepower

Legend's floatplane offering boasts advantages. "It weighs less than comparable aircraft, cost less, and came with the added advantage of doors and windows on both sides of the cockpit," observed the company. This design feature — not present on the original Piper models — is especially appropriate for float-equipped aircraft, offering egress from either side while docking.

Legend FloatCub comes standard with dual entry doors and windows, dual wing tanks, a larger cabin, and electric start (also not on Piper's iconic original). "You have a choice of engines, including the 100-horsepower

A key phrase for this website is "Affordable Aviation" (in fact, we bought AffordableAviation.com for future use). Our focus is on aircraft that can work within the budgets of many recreational or sport pilots. Reading about bizjets or self-flying drones in major magazines may be interesting but those of us who love to fly prefer flying machines we can genuinely afford.

A kit-built aircraft is one way to make airplanes more affordable, and more personal. The great news is you have many wonderful choices. What you may not have is time and that's why this article covers Merlin PSA.

How much time must you invest to get airborne? Would you believe a mere two weeks? Many kits ask for months, even years of your labor plus a place to do this work. If you love the craftsmanship, that may be fine but if you build so you can fly, why not have the process be easier and swifter?

A key phrase for this website is "Affordable Aviation" (in fact, we bought AffordableAviation.com for future use). Our focus is on aircraft that can work within the budgets of many recreational or sport pilots. Reading about bizjets or self-flying drones in major magazines may be interesting but those of us who love to fly prefer flying machines we can genuinely afford.

A kit-built aircraft is one way to make airplanes more affordable, and more personal. The great news is you have many wonderful choices. What you may not have is time and that's why this article covers Merlin PSA.

How much time must you invest to get airborne? Would you believe a mere two weeks? Many kits ask for months, even years of your labor plus a place to do this work. If you love the craftsmanship, that may be fine but if you build so you can fly, why not have the process be easier and swifter?

To see for myself, I went to observe a Merlin PSA under construction.

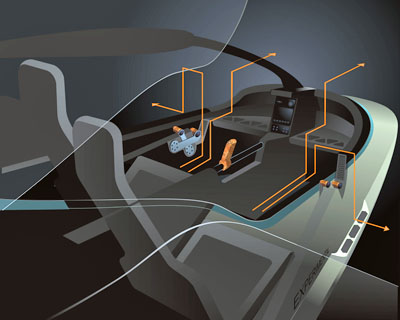

Matched-hole construction pilot holes must still be drilled to the finished size before riveting can begin. With precision matched-hole methods, Chip notes the holes are punched to the correct rivet size, ready to be attached with temporary clecos. Multiplied by thousands of rivet holes, this represents large time savings.

Many components — the entire horizontal stabilizer and elevator, for instance — come significantly pre-assembled. Every fifth hole has a temporary rivet securing the part. The temp rivet is color marked and after the builder rivets the surrounding holes, he replaces the temporary. This idea is widely used on the Merlin PSA quick build kit.

In addition, a Merlin QBK airframe includes spars and sub-assemblies that are factory riveted together (photo). All parts in the QBK are pre-fabricated and pre-drilled but major portions are delivered in fully finished form. Even paint priming is already done in many areas. For first-time home builders, the combination makes for a far easier set of tasks. It also helps assure builder and FAA that the job is done correctly.

To see for myself, I went to observe a Merlin PSA under construction.

Matched-hole construction pilot holes must still be drilled to the finished size before riveting can begin. With precision matched-hole methods, Chip notes the holes are punched to the correct rivet size, ready to be attached with temporary clecos. Multiplied by thousands of rivet holes, this represents large time savings.

Many components — the entire horizontal stabilizer and elevator, for instance — come significantly pre-assembled. Every fifth hole has a temporary rivet securing the part. The temp rivet is color marked and after the builder rivets the surrounding holes, he replaces the temporary. This idea is widely used on the Merlin PSA quick build kit.

In addition, a Merlin QBK airframe includes spars and sub-assemblies that are factory riveted together (photo). All parts in the QBK are pre-fabricated and pre-drilled but major portions are delivered in fully finished form. Even paint priming is already done in many areas. For first-time home builders, the combination makes for a far easier set of tasks. It also helps assure builder and FAA that the job is done correctly.

Merlin QBK also includes composite gear, wheels, brakes, control and fuel systems. The overall basic airframe costs only $16,500.

You will need the firewall-forward package involving an engine mount, nose cowl, throttle, oil tank, exhaust, propeller, spinner, air filter, radiator, plus related hardware and fittings. Add another $3,800 (now $20,300).

Your choice of powerplant presently includes Rotax 582: 65HP Electric Start, B Drive, Oil Injected for $6,950 or a HKS 700E 4-Stroke for $12,000 ($27,250 to $32,300). An electric propulsion option remains in testing but is coming.

Merlin QBK also includes composite gear, wheels, brakes, control and fuel systems. The overall basic airframe costs only $16,500.

You will need the firewall-forward package involving an engine mount, nose cowl, throttle, oil tank, exhaust, propeller, spinner, air filter, radiator, plus related hardware and fittings. Add another $3,800 (now $20,300).

Your choice of powerplant presently includes Rotax 582: 65HP Electric Start, B Drive, Oil Injected for $6,950 or a HKS 700E 4-Stroke for $12,000 ($27,250 to $32,300). An electric propulsion option remains in testing but is coming.

Instruments, interior, options, and paint will add more but Aeromarine LSA owner Chip Erwin reports you can get airborne for around $35,000. With the Rotax 582, that expense looks achievable and those who prefer four strokes could still finish for $40-45,000. Such investments purchase quite a bit of airplane for a sum many can afford.

Instruments, interior, options, and paint will add more but Aeromarine LSA owner Chip Erwin reports you can get airborne for around $35,000. With the Rotax 582, that expense looks achievable and those who prefer four strokes could still finish for $40-45,000. Such investments purchase quite a bit of airplane for a sum many can afford.

Seamax will join Embry-Riddle Research Park’s Customized Business Acceleration Program, the aeronautical university based in Daytona Beach announced on July 3rd, 2017.

Seamax will join Embry-Riddle Research Park’s Customized Business Acceleration Program, the aeronautical university based in Daytona Beach announced on July 3rd, 2017.

For AirMax, which recently reentered the U.S. market after a business reorganization (see

For AirMax, which recently reentered the U.S. market after a business reorganization (see

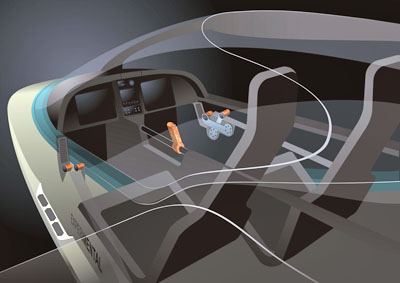

Terrafugia first announced their Transition roadable airplane in 2006, flying a proof-of-concept aircraft in 2009 along with a demonstration before attendees of

Terrafugia first announced their Transition roadable airplane in 2006, flying a proof-of-concept aircraft in 2009 along with a demonstration before attendees of  The electric motors that are hidden inside the body during ground operations allow the TF-X to takeoff vertically before morphing,

The electric motors that are hidden inside the body during ground operations allow the TF-X to takeoff vertically before morphing,  The ease of the trip in one of our modern flying machines with a big digital screen showing the way could lull you into crossing a large lake between you and your destination.

Midway across the lake, your engine unexpectedly sputters and stops. You calmly run through your checklist. Nothing appears amiss. You try restarting but the engine won't cooperate. Anywhere you look it's the same distance to land. You calculate you can't glide far enough.

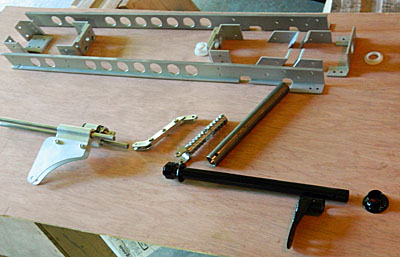

The ease of the trip in one of our modern flying machines with a big digital screen showing the way could lull you into crossing a large lake between you and your destination.

Midway across the lake, your engine unexpectedly sputters and stops. You calmly run through your checklist. Nothing appears amiss. You try restarting but the engine won't cooperate. Anywhere you look it's the same distance to land. You calculate you can't glide far enough.

I'll tell you from my four trips to the Bahamas flying that such crossings completely out of sight of land were enormously more enjoyable with a parachute than without. I knew I had a way out if the worst happened.

Magnum Parachutes offers rocket-deployed systems for a wide variety of airplanes. They are supplied from a U.S. importer who has all the credentials to do so competently and safely.

I'll tell you from my four trips to the Bahamas flying that such crossings completely out of sight of land were enormously more enjoyable with a parachute than without. I knew I had a way out if the worst happened.

Magnum Parachutes offers rocket-deployed systems for a wide variety of airplanes. They are supplied from a U.S. importer who has all the credentials to do so competently and safely.  Let's make an important point right up front. Seaplanes cost more than land planes. A fully-built, ASTM-compliant LSA seaplane starts at $150,000 and can go way up from that point. With a boat hull and retractable gear, of course, these water birds cost more to manufacture.

Must seaplanes be so costly? Fortunately, no! Aero Adventure manufactures a surprisingly affordable light seaplane kit.

With the Suzuki-based

Let's make an important point right up front. Seaplanes cost more than land planes. A fully-built, ASTM-compliant LSA seaplane starts at $150,000 and can go way up from that point. With a boat hull and retractable gear, of course, these water birds cost more to manufacture.

Must seaplanes be so costly? Fortunately, no! Aero Adventure manufactures a surprisingly affordable light seaplane kit.

With the Suzuki-based  Hammerhead "canard sponson" — Although it looks like (and is) an add-on feature, this could easily catch on for Aventura buyers and current owners. Dispensing with the wing-mounted sponsons you see in the nearby photos, their canard sponson offers more than a cool look.

These sponsons do the same job as the wing-mounted ones, namely keep the wings out of the water on turns or in moving water. However, since you can also walk on them, they aid entry, give you a platform in the water — for fishing, as one example — and they eliminate the drag of the tubing structure to hold the wing versions. "They actually develop a small amount of extra lift," said business owner Alex Rolinski.

This is no Icon A5-inspired idea. The canard sponson idea was first conceived under the leadership of Carlos Pereyra, a previous owner of this company who was something of a guru about fiberglass construction. The prototype was first fitted in early 2000 on a 1998 Aventura for a kit builder who wanted to explore the idea.

The original was built of fiberglass and used an interior aluminum tubular structure. It also had extra fuel in the sponsons, but when Alex and his group brought back the canard sponson, they removed the fuel tanks. Aventura carries plenty of fuel in a tank aft of the seats.

Hammerhead "canard sponson" — Although it looks like (and is) an add-on feature, this could easily catch on for Aventura buyers and current owners. Dispensing with the wing-mounted sponsons you see in the nearby photos, their canard sponson offers more than a cool look.

These sponsons do the same job as the wing-mounted ones, namely keep the wings out of the water on turns or in moving water. However, since you can also walk on them, they aid entry, give you a platform in the water — for fishing, as one example — and they eliminate the drag of the tubing structure to hold the wing versions. "They actually develop a small amount of extra lift," said business owner Alex Rolinski.

This is no Icon A5-inspired idea. The canard sponson idea was first conceived under the leadership of Carlos Pereyra, a previous owner of this company who was something of a guru about fiberglass construction. The prototype was first fitted in early 2000 on a 1998 Aventura for a kit builder who wanted to explore the idea.

The original was built of fiberglass and used an interior aluminum tubular structure. It also had extra fuel in the sponsons, but when Alex and his group brought back the canard sponson, they removed the fuel tanks. Aventura carries plenty of fuel in a tank aft of the seats.

"Aventura with these canard sponsons flew fine," added Alex, "but the assembly was heavy." Eliminating the fuel tanks considerably lightened the component. "They are made of very dense and very light foam," said Alex, "The construction uses technology borrowed from boats and is very strong."

Installation can be done to older Aventura seaplanes. Two 2.25-inch holes are cut in each side of hull but this is not a structural issue as the hull is independent of the airplane's structure. Nothing is fiberglassed to the hull but the assembly conforms with a snug fit. "One aluminum tube runs under your knees and another behind the seat, continuing through the hull to protrude on the other side," explained Alex. The canard sponsons extend 43 inches from each side. They have a taper from 44 inches of chord to 33 inches near the sponson. This is an all-new sponson design; it is not the wing mounted one moved inboard.

"They work well in water and in-flight cruise," Alex noted. Drag is reduced due to component's overall shape as it eliminates support-tube drag from the original wing-mounted sponsons. Aventura's retractable wheels tuck behind the sponson showing slightly above the upper surface. "The sponsons have no effect on turning; you still maneuver in the water with rudder and prop blast."

"Aventura with these canard sponsons flew fine," added Alex, "but the assembly was heavy." Eliminating the fuel tanks considerably lightened the component. "They are made of very dense and very light foam," said Alex, "The construction uses technology borrowed from boats and is very strong."

Installation can be done to older Aventura seaplanes. Two 2.25-inch holes are cut in each side of hull but this is not a structural issue as the hull is independent of the airplane's structure. Nothing is fiberglassed to the hull but the assembly conforms with a snug fit. "One aluminum tube runs under your knees and another behind the seat, continuing through the hull to protrude on the other side," explained Alex. The canard sponsons extend 43 inches from each side. They have a taper from 44 inches of chord to 33 inches near the sponson. This is an all-new sponson design; it is not the wing mounted one moved inboard.

"They work well in water and in-flight cruise," Alex noted. Drag is reduced due to component's overall shape as it eliminates support-tube drag from the original wing-mounted sponsons. Aventura's retractable wheels tuck behind the sponson showing slightly above the upper surface. "The sponsons have no effect on turning; you still maneuver in the water with rudder and prop blast."

Support for Buyers — Beside making airframes in kit form, Aero Advenure does regular refurbishment of previously-built Aventuras. "We have two Aventura IIs in inventory right now. One is a 2006 model with just 74 hours on it; another is a 2009 model that has close to 400 hours logged," Alex said. I predict these won't last long but Aero Adventure will happily make more at their DeLand, Florida location (right next door to Aerolite 103 manufacturer,

Support for Buyers — Beside making airframes in kit form, Aero Advenure does regular refurbishment of previously-built Aventuras. "We have two Aventura IIs in inventory right now. One is a 2006 model with just 74 hours on it; another is a 2009 model that has close to 400 hours logged," Alex said. I predict these won't last long but Aero Adventure will happily make more at their DeLand, Florida location (right next door to Aerolite 103 manufacturer,  Aerotrek

Aerotrek "Funny enough," Rob wrote, "for the last nine years since I also began bringing the Aeropro taildraggers into the U.S., where I originally only brought in the tricycle-gear planes. Our sales have been almost exactly 50/50 tricycle/taildragger. In the last 10 months, though, the ratio has swung heavily to tricycle-gear."

Why?

"I think there are a number of reasons, including the people buying planes tend to be those who had been holding back a bit waiting for the new Medical rules to be a great deal more liberal than they turned out to be. I think they were hoping for the same as our LSA, no-FAA-medical-required rules."

"Also, about a year ago I began promoting our A240 tricycle-gear plane with tundra tires, and people are sort of eating ‘em up." Rob said most people now order their new A240 with the standard tires and wheel pants, "but also with the optional wide front fork kit so they can quick and easy switch between standard tires and wheel pants to biggie tundra tires."

"Funny enough," Rob wrote, "for the last nine years since I also began bringing the Aeropro taildraggers into the U.S., where I originally only brought in the tricycle-gear planes. Our sales have been almost exactly 50/50 tricycle/taildragger. In the last 10 months, though, the ratio has swung heavily to tricycle-gear."

Why?

"I think there are a number of reasons, including the people buying planes tend to be those who had been holding back a bit waiting for the new Medical rules to be a great deal more liberal than they turned out to be. I think they were hoping for the same as our LSA, no-FAA-medical-required rules."

"Also, about a year ago I began promoting our A240 tricycle-gear plane with tundra tires, and people are sort of eating ‘em up." Rob said most people now order their new A240 with the standard tires and wheel pants, "but also with the optional wide front fork kit so they can quick and easy switch between standard tires and wheel pants to biggie tundra tires."

"Our regular A240 tundra tires are an 18-inch diameter tire on the mains and a 15-inch tire on the front. We can also put a 22-inch tire on the mains and an 18-inch tire on the front (photo)," explained Rob. "This works really, really well!"

"Of course, with our A220 taildragger we can put even bigger tires on the plane." Pictured is the most recent A220 delivered with the 26-inch diameter Alaska Bushwheels tires.

Regarding instrument panel options, Rob added, "Our latest-version instrument panel allows for an full-size (9.7-inch) iPad to be mounted on the panel horizontally with ADS-B showing the FAA aircraft traffic and weather. This makes for an extremely user-friendly and information rich panel that makes flying easier and safer. We offer the 2020-compliant ADS-B In/Out system for just $1,495 as an option for our planes."

"Our regular A240 tundra tires are an 18-inch diameter tire on the mains and a 15-inch tire on the front. We can also put a 22-inch tire on the mains and an 18-inch tire on the front (photo)," explained Rob. "This works really, really well!"

"Of course, with our A220 taildragger we can put even bigger tires on the plane." Pictured is the most recent A220 delivered with the 26-inch diameter Alaska Bushwheels tires.

Regarding instrument panel options, Rob added, "Our latest-version instrument panel allows for an full-size (9.7-inch) iPad to be mounted on the panel horizontally with ADS-B showing the FAA aircraft traffic and weather. This makes for an extremely user-friendly and information rich panel that makes flying easier and safer. We offer the 2020-compliant ADS-B In/Out system for just $1,495 as an option for our planes."

Aerotrek kits — "I get lots of email and calls asking about 'kits.' We don’t sell kits, never have, and never will sell the Aeropro planes as kits (Aeropro is the European manufacturer of his Aerotrek aircraft.) "I refer them to [other companies] though they usually figure out they will probably do better to buy one of our ready-to-fly SLSA planes than buy a kit."

Still climbing the charts — "Business is going good. We’re sold-out until the two planes that will arrive in early-November, and last week I sold one of those two planes." For years, Rob has sold out his aircraft in process. In speaking to many of his customers at airshows and elsewhere, I cannot think of one that did anything but rave about Rob's sense of customer service, no doubt a reason for his continuing success.

Aerotrek kits — "I get lots of email and calls asking about 'kits.' We don’t sell kits, never have, and never will sell the Aeropro planes as kits (Aeropro is the European manufacturer of his Aerotrek aircraft.) "I refer them to [other companies] though they usually figure out they will probably do better to buy one of our ready-to-fly SLSA planes than buy a kit."

Still climbing the charts — "Business is going good. We’re sold-out until the two planes that will arrive in early-November, and last week I sold one of those two planes." For years, Rob has sold out his aircraft in process. In speaking to many of his customers at airshows and elsewhere, I cannot think of one that did anything but rave about Rob's sense of customer service, no doubt a reason for his continuing success.

“BasicMed” — "This thing has, from everything I can tell, turned-out to be a bummer/non-starter for just about everybody that might have been interested in LSA-type aircraft. Some of these were holding back, hoping that the pending new rules were going to just do away with the Third Class Medical completely. Instead, what we got [BasicMed] really won’t work well, or whatsoever, for most people that might buy our sort of LSA planes. So, they are back."

What Rob says here is similar to what I have heard from many other LSA or light kit vendors. While I hear the new program is working well for some GA pilots who want to keep flying their older certified fill-in-the-blank airplane, BasicMed nonetheless comes with complications and challenges.

Meanwhile, Rob continues to rack up sales and climb the charts while putting smiles on the faces of his pilots. You have to applaud that performance.

“BasicMed” — "This thing has, from everything I can tell, turned-out to be a bummer/non-starter for just about everybody that might have been interested in LSA-type aircraft. Some of these were holding back, hoping that the pending new rules were going to just do away with the Third Class Medical completely. Instead, what we got [BasicMed] really won’t work well, or whatsoever, for most people that might buy our sort of LSA planes. So, they are back."

What Rob says here is similar to what I have heard from many other LSA or light kit vendors. While I hear the new program is working well for some GA pilots who want to keep flying their older certified fill-in-the-blank airplane, BasicMed nonetheless comes with complications and challenges.

Meanwhile, Rob continues to rack up sales and climb the charts while putting smiles on the faces of his pilots. You have to applaud that performance.