AirMax SeaMax — Icon A5 — Vickers Wave — MVP — Lisa Akoya… you only need look at the best promoted brands to see that arguably the most innovative ideas in light aircraft are coming from the LSA seaplane sector. Each of these is a great example of visionary engineering.

Others LSA or light kit seaplane developments — Searey, Mermaid, ATOL Avion, Aero Adventure, among others — are somewhat more conventional but that’s reassuring to some potential buyers. All these names have one enormous advantage. They have practical field experience. Of the five in the first paragraph, only SeaMax has a longer period of use by owners in regular operation.

Now consider Equator Aircraft P2 Xcursion, an electric hybrid seaplane with several compelling ideas. I wrote about this in an article two years ago; now we have an update.

AirMax SeaMax — Icon A5 — Vickers Wave — MVP — Lisa Akoya… you only need look at the best promoted brands to see that arguably the most innovative ideas in light aircraft are coming from the LSA seaplane sector. Each of these is a great example of visionary engineering.

Others LSA or light kit seaplane developments — Searey, Mermaid, ATOL Avion, Aero Adventure, among others — are somewhat more conventional but that’s reassuring to some potential buyers. All these names have one enormous advantage. They have practical field experience. Of the five in the first paragraph, only SeaMax has a longer period of use by owners in regular operation.

Now consider Equator Aircraft P2 Xcursion, an electric hybrid seaplane with several compelling ideas. I wrote about this in an article two years ago; now we have an update.Sleek, Sexy Electric Light-Sport Seaplane

AirMax SeaMax — Icon A5 — Vickers Wave — MVP — Lisa Akoya… you only need look at the best promoted brands to see that arguably the most innovative ideas in light aircraft are coming from the LSA seaplane sector. Each of these is a great example of visionary engineering.

Others LSA or light kit seaplane developments — Searey, Mermaid, ATOL Avion, Aero Adventure, among others — are somewhat more conventional but that’s reassuring to some potential buyers. All these names have one enormous advantage. They have practical field experience. Of the five in the first paragraph, only SeaMax has a longer period of use by owners in regular operation.

After Aero 2017, aeronautical journalist extraordinaire, Marino Boric (website), wrote, “The Norwegian company, a typical start-up enterprise, successfully impressed the public with its P2 Xcursion at Aero.”

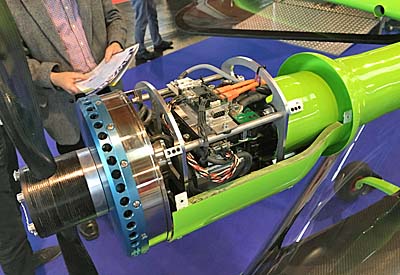

“Equator has created an interesting amphibious two seater with a hybrid propulsion system (EHPS) where the prop on the vertical stabilizer is driven by a 100kW (134 horsepower) electric motor which receives electric energy from a remotely-located Wankel combustion engine/generator power unit …and/or from a battery pack.”

Thanks, Marino. We will have more from him still to follow.

Equator’s team lead by CEO Tomas Brødreskift said, “We imagine hybrid bio-based technologies as a bridging technology, [one] that can provide green flight, but still have suitable long range capability.” Since “range anxiety” seems to be the major challenge facing electric car producers, maybe Tomas and Equator are on to something.

The company views four particular attributes of Equator

- Floatwing — removes the need for external high drag support geometries, and provides high stability

- Merged Hull Geometry — fuselage has an aerodynamic forward geometry merged with the boat hull further back for minimizing drag on the boat hull section

- Electric Motor — gives us smooth aerodynamics and lower weight at the same time; we get all the bulk and weight down in the hull for optimized stability in water

- Laminar Flow — drag is kept low over all with a laminar flow fuselage, canopy and airfoils

image by Mario Boric at Aero 2017

An “air lubrication system” is an experimental method designed to lower drag when taking off from water. Air is pumped through tiny holes in the hull to reduce friction.

When in water, the M97 electric engine can be reversed when you pull the throttle all the way back and actuate the wheel brakes. “You can brake and reverse the plane aerodynamically in water, a dream for any seaplane pilot,” said Equator.

The rudder fly-by-wire and nose gear drive-by-wire are more experimental technologies. “We believe these may make it simpler for the prospective owner and pilot to learn how to fly. No more hand and foot coordination, here you can put your feet up high and use your hands only for all control inputs. A video on the company’s website shows twisting the joystick like a motorcycle throttle to move the rudder. This is clever but non-standard, which may create resistance from experienced pilots. However, it shows their out-of-the-box thinking.

P2 Xcursion’s power system is comprised of three elements:

- Internal Combustion Engine — WST KKM 352 Wankel producing 57kW (76 horsepower) weighing 99 pounds (45 kg)

- Generator — Engiro G60 producing 60kW, water cooled weighing 33 pounds (15 kg)

- Electric Motor — Engiro M97 Electric producing 97 kW (130 horsepower) weighing 71 pounds ( 32 kg)

image by Mario Boric at Aero 2017

All three elements weight 203 pounds (92 kg), which isn’t bad for 130 horsepower compared to an equivalent gasoline engine thrust… but that may be an inadequate comparison. Electric motors are known for their high torque, just what is needed for a seaplane trying to leave the water. On balance, though, keeping such a multi-element system in perfect operating condition requires different skills than maintaining a gasoline engine. Additional training seems needed for aviation mechanics to perform upkeep on such a hybrid.

Avionics are supplied by an MGL iEFIS with remote transponder and radio. For their propeller, Equator chose a DUC Flash with custom DUC hub and spinner.

P2 Xcursion is interesting enough to keep following during its test flying program. Marino reported, “The prototype should soon start with ground/water testing and the maiden flight is planned for summer 2017.”

Go explore Equator’s website for yourself.

AirMax SeaMax — Icon A5 — Vickers Wave — MVP — Lisa Akoya… you only need look at the best promoted brands to see that arguably the most innovative ideas in light aircraft are coming from the LSA seaplane sector. Each of these is a great example of visionary engineering.

Others LSA or light kit seaplane developments — Searey, Mermaid, ATOL Avion, Aero Adventure, among others — are somewhat more conventional but that’s reassuring to some potential buyers. All these names have one enormous advantage. They have practical field experience. Of the five in the first paragraph, only SeaMax has a longer period of use by owners in regular operation.

Now consider Equator Aircraft P2 Xcursion, an electric hybrid seaplane with several compelling ideas. I wrote about this in an article two years ago; now we have an update.

AirMax SeaMax — Icon A5 — Vickers Wave — MVP — Lisa Akoya… you only need look at the best promoted brands to see that arguably the most innovative ideas in light aircraft are coming from the LSA seaplane sector. Each of these is a great example of visionary engineering.

Others LSA or light kit seaplane developments — Searey, Mermaid, ATOL Avion, Aero Adventure, among others — are somewhat more conventional but that’s reassuring to some potential buyers. All these names have one enormous advantage. They have practical field experience. Of the five in the first paragraph, only SeaMax has a longer period of use by owners in regular operation.

Now consider Equator Aircraft P2 Xcursion, an electric hybrid seaplane with several compelling ideas. I wrote about this in an article two years ago; now we have an update.

Does any aviator in the country not know the name

Does any aviator in the country not know the name  “This is the time of year when we go all out by offering spectacular discounts on our most popular products and provide a chance for our loyal customers to meet our vendors,” said Aircraft Spruce representatives. You might even win a free AvMap Engibox.

“This is the time of year when we go all out by offering spectacular discounts on our most popular products and provide a chance for our loyal customers to meet our vendors,” said Aircraft Spruce representatives. You might even win a free AvMap Engibox.

Rotax Aircraft Engines

Rotax Aircraft Engines

BRM has been flying a prototype aircraft with the 915 iS engine installed. Their preliminary flying shows some solid results.

BRM has been flying a prototype aircraft with the 915 iS engine installed. Their preliminary flying shows some solid results.

Mainstream media outfits exploded with news of Google’s flying car. Although such news outlets rarely seem to notice recreational aviation other than when an accident occurs, the reports I read did a respectable job of covering flying car projects we already knew about (reported

Mainstream media outfits exploded with news of Google’s flying car. Although such news outlets rarely seem to notice recreational aviation other than when an accident occurs, the reports I read did a respectable job of covering flying car projects we already knew about (reported  Funded by Google founder, Larry Page — an uber rich tech personality — Kitty Hawk is not simply an exploratory project. They actually plan to sell this cool little rig. Flyer is an open-seated, 220-pound empty weight octocopter with seat (saddle?) for one person. Powered by eight battery-powered propellers, it is a man-carrying drone for sport flying.

Funded by Google founder, Larry Page — an uber rich tech personality — Kitty Hawk is not simply an exploratory project. They actually plan to sell this cool little rig. Flyer is an open-seated, 220-pound empty weight octocopter with seat (saddle?) for one person. Powered by eight battery-powered propellers, it is a man-carrying drone for sport flying.

“Vessel CEO was present for the ground testing and first flight of the KLA-100,” said Mr. Kiman Seo, CEO of Vessel Co., Ltd. “Vessel is running a parallel development and flight test program in South Korea to gather as much experience for certification in Korea.”

“Vessel CEO was present for the ground testing and first flight of the KLA-100,” said Mr. Kiman Seo, CEO of Vessel Co., Ltd. “Vessel is running a parallel development and flight test program in South Korea to gather as much experience for certification in Korea.” KLA-100 is powered by 100 horsepower (74 KW) from a fuel injected

KLA-100 is powered by 100 horsepower (74 KW) from a fuel injected  To reassure customers old and new, Masschelein added, “The Remos GX is a major part of our plans for the future.”

To reassure customers old and new, Masschelein added, “The Remos GX is a major part of our plans for the future.”

SWAN is a single-seater ultralight aircraft created and manufactured by

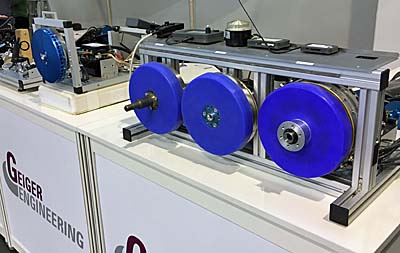

SWAN is a single-seater ultralight aircraft created and manufactured by  The Romanian company displayed a standard Polini-equipped aircraft at Aero 2017, but also had a Geiger-equipped alternative. This was still as a prototype, Roy clarified.

The Romanian company displayed a standard Polini-equipped aircraft at Aero 2017, but also had a Geiger-equipped alternative. This was still as a prototype, Roy clarified. John Hunter has extensive experience with Drifter, AirCam, and several Aeroprakt models. Recently, he has been in Italy visiting Innovaviation to conduct the first test flights.

John Hunter has extensive experience with Drifter, AirCam, and several Aeroprakt models. Recently, he has been in Italy visiting Innovaviation to conduct the first test flights. “The aircraft is stable, yet responsive. It does not display control sensitivity in any axis, yet control response is very positive. It can easily be flown with neutral trim throughout it’s speed range, including all three stages of flap deployment (15º, 30º, and 45º).

“The aircraft is stable, yet responsive. It does not display control sensitivity in any axis, yet control response is very positive. It can easily be flown with neutral trim throughout it’s speed range, including all three stages of flap deployment (15º, 30º, and 45º). “The first flap position (15º) is recommended for takeoff. On turf, the nose gear can be rotated in 5 seconds, and liftoff occurs 8 seconds from standstill, with winds calm and a takeoff weight of 950 pounds (solo flight with 50% fuel). Takeoff roll is approximately 320 feet. Standard day rate of climb at 80 mph is 1,050 feet per minute.

“The first flap position (15º) is recommended for takeoff. On turf, the nose gear can be rotated in 5 seconds, and liftoff occurs 8 seconds from standstill, with winds calm and a takeoff weight of 950 pounds (solo flight with 50% fuel). Takeoff roll is approximately 320 feet. Standard day rate of climb at 80 mph is 1,050 feet per minute. FX 1 was designed to conform to American regulations. John’s goal has been to establish production of the FX1 in the United States, both for the domestic market and for export. “I have been working with Innovaviation over the past two years towards that end, and having just flown the plane, we are definitely on the right track,” John expressed.

FX 1 was designed to conform to American regulations. John’s goal has been to establish production of the FX1 in the United States, both for the domestic market and for export. “I have been working with Innovaviation over the past two years towards that end, and having just flown the plane, we are definitely on the right track,” John expressed.

Prominently displayed in front of the Rotax Aircraft Engines exhibit at Sun ‘n Fun — right at the main entrance to the large spring show — was a strikingly-painted Searey kit-built aircraft (photo). Why? The mission was to showcase how a Rotax-powered amphibian aircraft can get more push… without complexity.

Prominently displayed in front of the Rotax Aircraft Engines exhibit at Sun ‘n Fun — right at the main entrance to the large spring show — was a strikingly-painted Searey kit-built aircraft (photo). Why? The mission was to showcase how a Rotax-powered amphibian aircraft can get more push… without complexity.

On Wednesday, April 5, the Global Show for General Aviation started for the 25th time. The 2017 edition opened with a record participation of 707 exhibitors from 39 countries, some 100 more than in 2016, presenting the best results in its history. Not only did more vendors attend this benchmark Aero, even the number of visitors numbers increased on first three days by six percent.

On Wednesday, April 5, the Global Show for General Aviation started for the 25th time. The 2017 edition opened with a record participation of 707 exhibitors from 39 countries, some 100 more than in 2016, presenting the best results in its history. Not only did more vendors attend this benchmark Aero, even the number of visitors numbers increased on first three days by six percent. The fair-chief, CEO Klaus Wellmann said: “It is now clear that our Aero is the most important business meeting for the aviation industry in Europe boasting many premieres.” As is often the case with this event, many novel aircraft were presented.

The fair-chief, CEO Klaus Wellmann said: “It is now clear that our Aero is the most important business meeting for the aviation industry in Europe boasting many premieres.” As is often the case with this event, many novel aircraft were presented.

Welcome to the new US Flight Expo. Less like Sun ‘n Fun and AirVenture with their airshow components and vast acreage of airplanes of all types, US Flight Expo will perhaps more closely resemble

Welcome to the new US Flight Expo. Less like Sun ‘n Fun and AirVenture with their airshow components and vast acreage of airplanes of all types, US Flight Expo will perhaps more closely resemble  Organized by Arion Lightning dealer and light aviation enthusiast Greg Hobbs, the sector we usually cover here on ByDanJohnson.com looks to be well represented. Consider the list below. The other shows are all in the eastern U.S., a phenomenon I’ve discussed with many people over the years. For whatever reason, no major show has come to dominate the expansive western U.S.

Organized by Arion Lightning dealer and light aviation enthusiast Greg Hobbs, the sector we usually cover here on ByDanJohnson.com looks to be well represented. Consider the list below. The other shows are all in the eastern U.S., a phenomenon I’ve discussed with many people over the years. For whatever reason, no major show has come to dominate the expansive western U.S. Vast Western landscapes can be incredibly beautiful as the photos show. Greg is a hardworking fellow who has been laboring to build this event for the benefit of airplane enthusiasts and the vendors who serve them. He said early May is pleasantly warm and temperate with deep blue skies.

Vast Western landscapes can be incredibly beautiful as the photos show. Greg is a hardworking fellow who has been laboring to build this event for the benefit of airplane enthusiasts and the vendors who serve them. He said early May is pleasantly warm and temperate with deep blue skies. Videoman Dave first pulled me aside to look at an unusual ultralight aircraft nestled in the homebuilt area hidden behind a row of porta-potties. It was a questionable (but, surprisingly not stinky) location for what I had to admit was one truly fascinating aircraft. Check out Lightning Bug!

Videoman Dave first pulled me aside to look at an unusual ultralight aircraft nestled in the homebuilt area hidden behind a row of porta-potties. It was a questionable (but, surprisingly not stinky) location for what I had to admit was one truly fascinating aircraft. Check out Lightning Bug! One look at the photos ought to explain but what you can’t see is that Lightning Bug weighs a mere 140 pounds and employs unorthodox control surfaces. I don’t think I’ve ever seen a three axis flying machine, ‘er… ultralight vehicle that comes in an amazing 114 pounds under the tight weight limit of Part 103.

One look at the photos ought to explain but what you can’t see is that Lightning Bug weighs a mere 140 pounds and employs unorthodox control surfaces. I don’t think I’ve ever seen a three axis flying machine, ‘er… ultralight vehicle that comes in an amazing 114 pounds under the tight weight limit of Part 103. A variety of materials were used to build this head-turning aircraft. Welded steel provides the basic structure with foam core and aluminum spar wings. Control surfaces are covered with see-through monokote as you’d find on many model aircraft, again hewing to Brian’s background.

A variety of materials were used to build this head-turning aircraft. Welded steel provides the basic structure with foam core and aluminum spar wings. Control surfaces are covered with see-through monokote as you’d find on many model aircraft, again hewing to Brian’s background.