Probably like a lot of you, I enjoy different kinds of flying but if asked to state one favorite, it’s an easy question to answer.

I’m a great enthusiast of soaring flight. Over decades of sampling a large number of aircraft of every description, I’m still drawn to a machine, which lacking any kind of powerplant, relies on the performance of the design and the skill of the pilot to stay aloft. I remain fascinated with locating rising columns of heated air. Circle well enough into one of these invisible thermals and you may be rewarded with an invigorating sensation of lift, of riding the swirling airmass thousands of feet into the air …silently. It’s mesmerizing to observe the ground fall away as you are propelled higher and higher.

You may never have felt such thing and you may be hesitant about launching into the air in an aircraft that will allow only one approach and landing per flight; no exceptions.

Probably like a lot of you, I enjoy different kinds of flying but if asked to state one favorite, it’s an easy question to answer.

I’m a great enthusiast of soaring flight. Over decades of sampling a large number of aircraft of every description, I’m still drawn to a machine, which lacking any kind of powerplant, relies on the performance of the design and the skill of the pilot to stay aloft. I remain fascinated with locating rising columns of heated air. Circle well enough into one of these invisible thermals and you may be rewarded with an invigorating sensation of lift, of riding the swirling airmass thousands of feet into the air …silently. It’s mesmerizing to observe the ground fall away as you are propelled higher and higher.

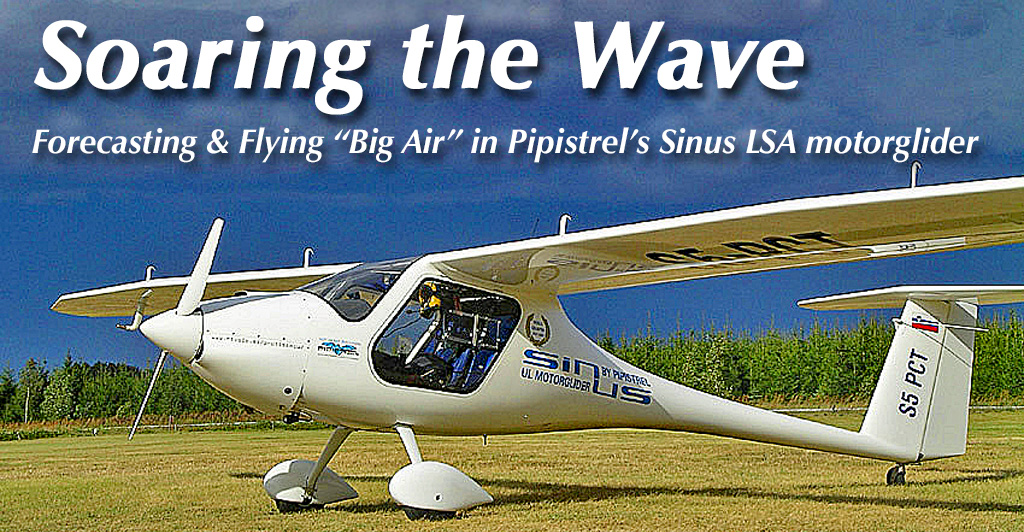

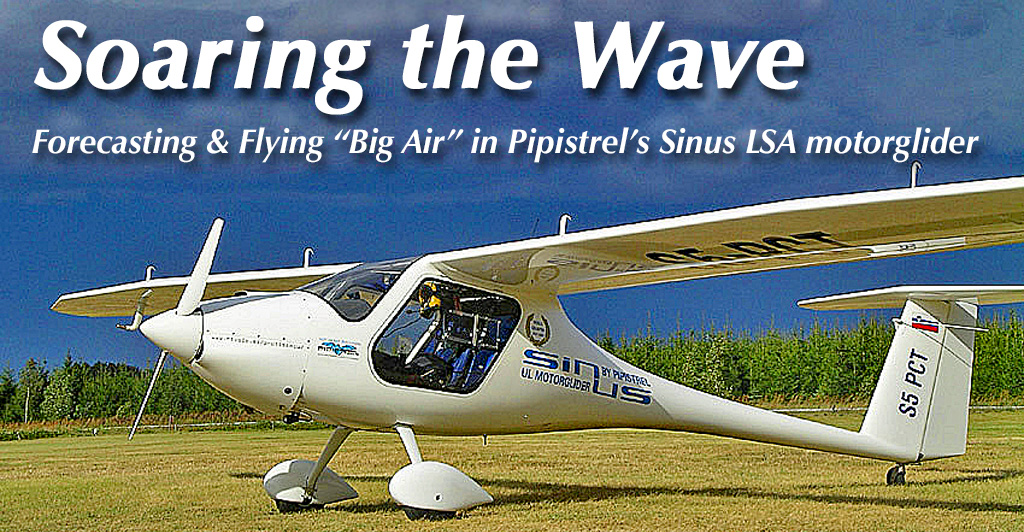

You may never have felt such thing and you may be hesitant about launching into the air in an aircraft that will allow only one approach and landing per flight; no exceptions.Let’s Get High… Really High, OK? Exploring the “Upper Atmosphere” in a Pipistrel Motorglider

Probably like a lot of you, I enjoy different kinds of flying but if asked to state one favorite, it’s an easy question to answer.

You may never have felt such thing and you may be hesitant about launching into the air in an aircraft that will allow only one approach and landing per flight; no exceptions. However, for those entranced by manipulating wisps of air to rise upward, a machine like Pipistrel’s Sinus is a thing of beauty.

Want to learn more? Let’s take a sample soaring flight. Even better, let’s investigate wave soaring.

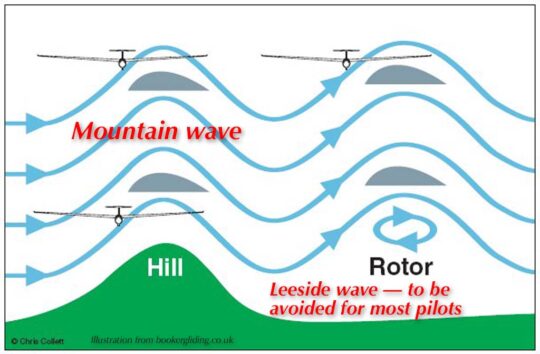

Riding the Wave

Some years back I flew with Pipistrel dealer, Robert Mudd, to more than 17,000 feet. Conditions would have allowed us to soar even higher but at Flight Level 180, you enter Class A airspace and we were not prepared for that. Lift was abundant, though, so we had to go find sinking air to stay out of controlled space.

Robert continues to be a soaring enthusiast, hailing from New Mexico. He relates the following story about flying a wave near Albuquerque. If you aren’t sure what wave is, read on.

Knowing about waves can help you better negotiate mountain flying.

“We took off about 10:15 AM and climbed west-northwest under Rotax power. Our home field elevation is 6,200 feet.

“The orientation of the wind aloft was not the best for wave to form. An ideal wind direction is 260 to 280 degrees so as to be perpendicular to the Sandia mountains, which rise to 10,500 feet. The wave was forecast to be at the northern end of the Sandia range, and be at an angle to the mountains. Wind aloft was about 230 degrees, not ideal by any means. This would be a good test of John’s forecasting method.

“We continued on a north-northwest track, climbing modestly at about 1.5 to 2 knots, about 150-200 feet per minute. The forecast was for stronger lift ahead so we continued. Sure enough, just where John had forecast stronger conditions, we found that. The best climb rate we saw was 3 knots or about 300 feet per minute. We stopped the climb at 17,910 feet. We could have gone higher, I think to at least 20,000 feet, but the wave window was not open.

“We turned around and more or less followed our track back, still in wave, but staying well below 18,000 feet.

“The view was fantastic. As we flew out of the region of better lift we started a long slow decent and turned slightly to the southeast toward home.

“We landed after 1.25 hours of flight time, about an hour of which was power off. Naturally, the landing was done power off. As we cleared the runway I un-feathered the prop, started the motor and taxied to the hangar.

“This illustrates the potential of research that can be done in a touring type motorglider. Because both pilot and researcher were side by side, coordinating the flight path was easy (unpowered sailplanes almost always have tandem seating). We were able to motor right to the area we wanted to explore, and, of course. always had a safety out with the motor.

“All in all, it was a flight to remember for the research, fellowship, and the fun of it.”

—Robert Mudd, October 2021

TECHNICAL SPECIFICATIONS

Pipistrel Sinus

LSA Motorglider

- Wingspan — 49 feet, 1.5 inches

- Wing Area — 132 square feet

- Length — 24 feet, 1 inch

- Height — 6 feet

- Maximum Takeoff Weight — 1,213 pounds

- Standard Empty Weight — 644 pounds (typical weight 661 pounds)

- Useful Load — 569 pounds

- Payload (with full fuel) — 471 pounds

- Stall Speed (best flaps) — 35 knots

- Maneuvering Speed — 76 knots

- Maximum Rate of Climb — 1,063 feet per minutes at 62 knots

- Minimum Sink Rate (a key soaring term) — 217 feet per minute

- Takeoff Ground Roll — 433 feet

- Glide Ratio — 27:1

- Power Cruise — 110 to 115 knot with 80 horsepower Rotax 912

- Fuel Capacity — 15.9 gallons

- Fuel in optional long-range tanks — 24. 6 gallons

- Fuel Consumption — 3.1 gallons per hour at 110 knots

- Configuration — Available in tail dragger or nosewheel

- Endurance — up to 7.5 hours

- Maximum Range — 850 nautical miles

- Propeller — Feathering propeller option (approved for LSA motorgliders)

- Cockpit Width — 44 inches

- Baggage — 55 pounds capacity with external access option

* You can also soar leeside wave but this is for experts only.

Here’s our video with Rand Vollmer. Hear from a Sinus expert about this high performing LSA motorglider.

Probably like a lot of you, I enjoy different kinds of flying but if asked to state one favorite, it’s an easy question to answer.

I’m a great enthusiast of soaring flight. Over decades of sampling a large number of aircraft of every description, I’m still drawn to a machine, which lacking any kind of powerplant, relies on the performance of the design and the skill of the pilot to stay aloft. I remain fascinated with locating rising columns of heated air. Circle well enough into one of these invisible thermals and you may be rewarded with an invigorating sensation of lift, of riding the swirling airmass thousands of feet into the air …silently. It’s mesmerizing to observe the ground fall away as you are propelled higher and higher.

You may never have felt such thing and you may be hesitant about launching into the air in an aircraft that will allow only one approach and landing per flight; no exceptions.

Probably like a lot of you, I enjoy different kinds of flying but if asked to state one favorite, it’s an easy question to answer.

I’m a great enthusiast of soaring flight. Over decades of sampling a large number of aircraft of every description, I’m still drawn to a machine, which lacking any kind of powerplant, relies on the performance of the design and the skill of the pilot to stay aloft. I remain fascinated with locating rising columns of heated air. Circle well enough into one of these invisible thermals and you may be rewarded with an invigorating sensation of lift, of riding the swirling airmass thousands of feet into the air …silently. It’s mesmerizing to observe the ground fall away as you are propelled higher and higher.

You may never have felt such thing and you may be hesitant about launching into the air in an aircraft that will allow only one approach and landing per flight; no exceptions.

Today the manufacturing of CGS’s Hawk line falls to two entities after the brand’s most recent rescuer, Terry Short, chose to focus on his own strengths. Terry had saved the design from its second owner after the original creator, Chuck, retired from the business. When Terry got busy building airplanes and supplying parts, he realized that it was a more diverse enterprise than originally anticipated. Therefore he was open when Bob Santom approached him.

Today the manufacturing of CGS’s Hawk line falls to two entities after the brand’s most recent rescuer, Terry Short, chose to focus on his own strengths. Terry had saved the design from its second owner after the original creator, Chuck, retired from the business. When Terry got busy building airplanes and supplying parts, he realized that it was a more diverse enterprise than originally anticipated. Therefore he was open when Bob Santom approached him. In 2017, Bob Santom and his wife Marlene came to agreement and the Santom family took over rights and production of all CGS Hawk single-seat aircraft. This includes the Classic, Arrow I, Sport, Plus, and Ultra. As he operates “CGS Hawk Single and Ultra,” Bob is assisted by his two sons, LB and Jonah, though the latter is part time as he has a full-time gig with Cirrus Design.

In 2017, Bob Santom and his wife Marlene came to agreement and the Santom family took over rights and production of all CGS Hawk single-seat aircraft. This includes the Classic, Arrow I, Sport, Plus, and Ultra. As he operates “CGS Hawk Single and Ultra,” Bob is assisted by his two sons, LB and Jonah, though the latter is part time as he has a full-time gig with Cirrus Design.  In 2019, Terry also reached agreement with

In 2019, Terry also reached agreement with  When Danny Dezauche took over the design, he did what he could, but I examined what he received and he faced a major challenge. The documentation needed quite a bit of work. Danny kept the brand alive but he was realistic about the daunting amount of work ahead. It was probably appropriate when

When Danny Dezauche took over the design, he did what he could, but I examined what he received and he faced a major challenge. The documentation needed quite a bit of work. Danny kept the brand alive but he was realistic about the daunting amount of work ahead. It was probably appropriate when  With Hawk, you just buy sewn Dacron “sails,” a term carried over from the days when such wing coverings were adapted from sailboat sails. You slip them on, tighten them up, and you are largely done. Years later, when replacement may be needed, you can simply buy a new set of sails, which is much lower cost and far less labor than recovering (though dope and fabric coverings may go many years with no need of replacement). Dacron sails are $3,100 so the covered kit price is $15,600 before engine.

With Hawk, you just buy sewn Dacron “sails,” a term carried over from the days when such wing coverings were adapted from sailboat sails. You slip them on, tighten them up, and you are largely done. Years later, when replacement may be needed, you can simply buy a new set of sails, which is much lower cost and far less labor than recovering (though dope and fabric coverings may go many years with no need of replacement). Dacron sails are $3,100 so the covered kit price is $15,600 before engine. Whatever your choice, the engine may run $3,000 to $6,000. Add a few instruments and a couple other refinements and your Hawk Ultra could total $22,000 to $25,000 in flying form.

Whatever your choice, the engine may run $3,000 to $6,000. Add a few instruments and a couple other refinements and your Hawk Ultra could total $22,000 to $25,000 in flying form.

Let’s keep a focus on aircraft affordability. Look, we love recreational aircraft. In how they deliver enjoyment, they are closer to boats, RVs, and motorcycles than they are to a Cirrus SR22 or a Bonanza.

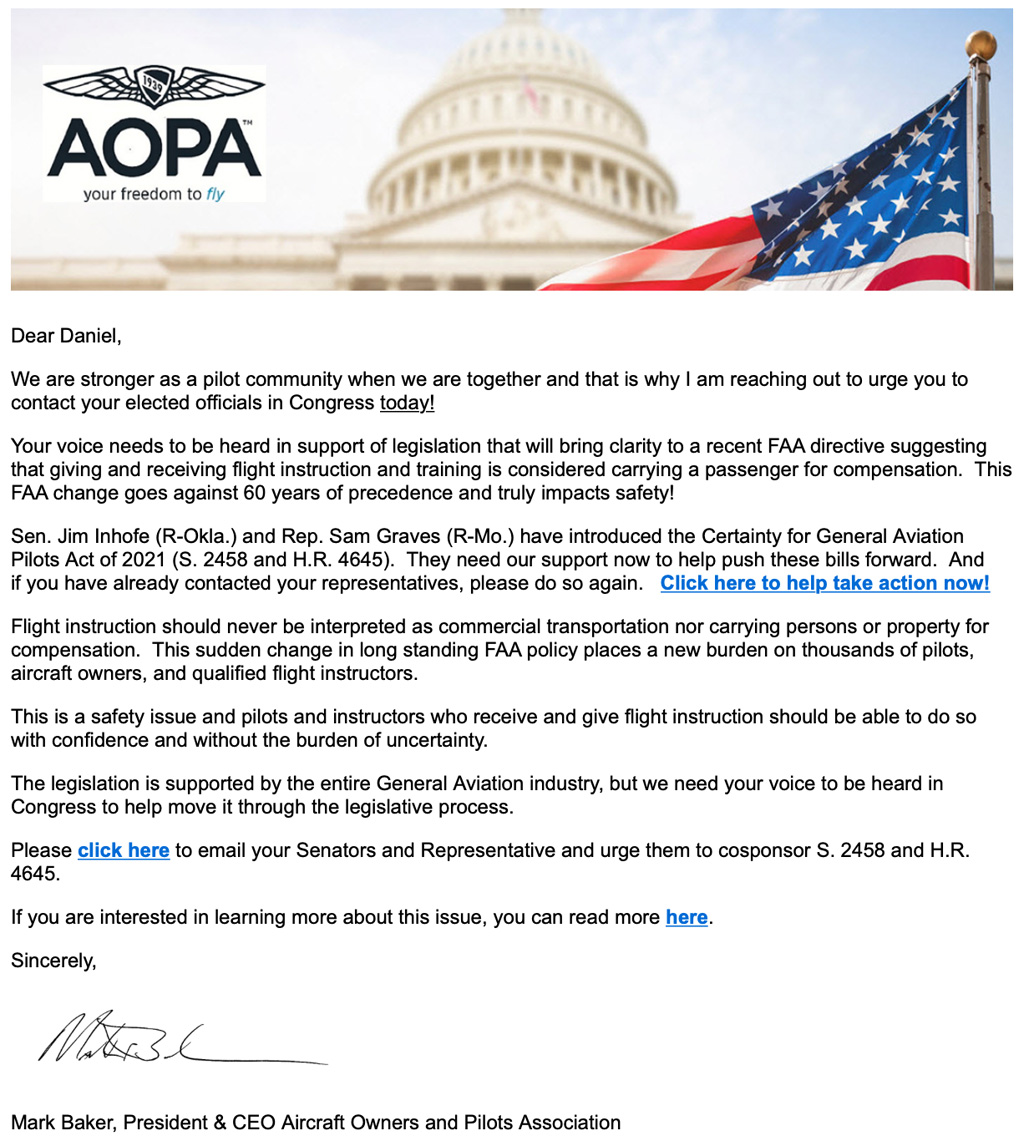

Let’s keep a focus on aircraft affordability. Look, we love recreational aircraft. In how they deliver enjoyment, they are closer to boats, RVs, and motorcycles than they are to a Cirrus SR22 or a Bonanza. FAA’s July 2021 enforcement action opened a Pandora’s Box and has dramatically affected flight instruction in recreational aircraft of many types.

FAA’s July 2021 enforcement action opened a Pandora’s Box and has dramatically affected flight instruction in recreational aircraft of many types. Based on many airshow conversations, I believe many of you share some qualities with Wes. He’s a longtime A&P mechanic who works for HondaJet in avionics using his electrical engineering background. Let’s just say he’s handy and knowledgeable. Many kit builders I’ve met also bring skills and experience to a project.

Based on many airshow conversations, I believe many of you share some qualities with Wes. He’s a longtime A&P mechanic who works for HondaJet in avionics using his electrical engineering background. Let’s just say he’s handy and knowledgeable. Many kit builders I’ve met also bring skills and experience to a project. In Wes’s case, his electrical engineering skills and hands-on experience encourages him to seek out interesting aircraft which have work remaining or repairs needed for its electrical system. You may possess particular skills you could apply similarly.

In Wes’s case, his electrical engineering skills and hands-on experience encourages him to seek out interesting aircraft which have work remaining or repairs needed for its electrical system. You may possess particular skills you could apply similarly. This method didn’t always work perfectly. An investment in a Van’s RV-3, for its engine in particular, proved to be a “learning experience.” Wes hoped he could energize a Beech Skipper that needed a more potent engine but a required STC turned out not to be available, so that project was less profitable.

This method didn’t always work perfectly. An investment in a Van’s RV-3, for its engine in particular, proved to be a “learning experience.” Wes hoped he could energize a Beech Skipper that needed a more potent engine but a required STC turned out not to be available, so that project was less profitable.

Numerous reports involve rising inflation in the last year. What’s driving this? Despite public spending at levels never seen before, inflation had seemed tame and the economy appears remarkably strong even after the last year and a half of dislocations and restrictions?

Numerous reports involve rising inflation in the last year. What’s driving this? Despite public spending at levels never seen before, inflation had seemed tame and the economy appears remarkably strong even after the last year and a half of dislocations and restrictions?

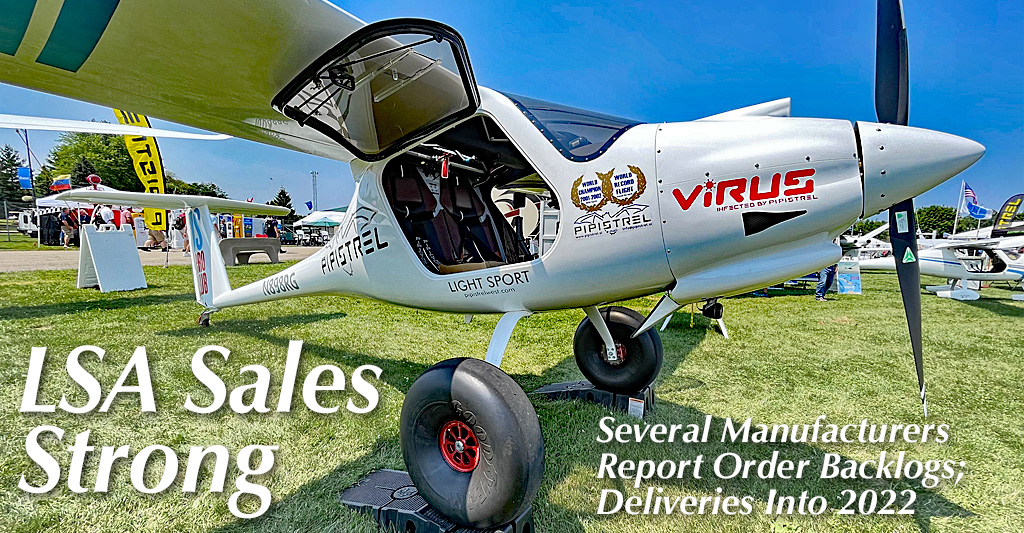

Numerous importers of LSA and other products have told me how their container shipping expenses have shot skyward faster than a Blue Origin space flight with a billionaire on board. I’ve heard many quote between double and triple the rates per container compared to a couple years ago. Welcome to the world of inflation-stimulated price increases combined with tariffs, sanctions, and taxes… all of which are on the rise globally.

Numerous importers of LSA and other products have told me how their container shipping expenses have shot skyward faster than a Blue Origin space flight with a billionaire on board. I’ve heard many quote between double and triple the rates per container compared to a couple years ago. Welcome to the world of inflation-stimulated price increases combined with tariffs, sanctions, and taxes… all of which are on the rise globally. The bad news is… until then, uncertainty is the watchword. When people don’t know what is ahead — either on the producer level or at the consumer level — individuals tend to hesitate. Aircraft sales people have full order books right now and hopefully that will sustain them through any dry spell.

The bad news is… until then, uncertainty is the watchword. When people don’t know what is ahead — either on the producer level or at the consumer level — individuals tend to hesitate. Aircraft sales people have full order books right now and hopefully that will sustain them through any dry spell.

I consistently promote that this website focuses on “affordable” aircraft. I used quotes because affordable literally means something different to every single individual. None of us has the same budget and our financial picture can change tomorrow.

I consistently promote that this website focuses on “affordable” aircraft. I used quotes because affordable literally means something different to every single individual. None of us has the same budget and our financial picture can change tomorrow.

Simply put, a LSA selling for $81,000 in 2021 is priced the same (in purchasing power) as $60,000 was in 2004 when the SP/LSA rule was announced at Oshkosh that year.

Simply put, a LSA selling for $81,000 in 2021 is priced the same (in purchasing power) as $60,000 was in 2004 when the SP/LSA rule was announced at Oshkosh that year.

On the final day of the

On the final day of the

Various other producers have adapted this general shape and developed their own versions. I’ve reported on at least six such: CH-750 (the original, along with the 701); ICP’s Savannah of Italy, SP30 from Russia, Sila from Serbia, and G1 from France. Even this list is not complete. G1 was reportedly modeled after yet another, the now-discontinued Alisport Puma. Clearly, this is a popular form of aircraft. Read G1 America’s

Various other producers have adapted this general shape and developed their own versions. I’ve reported on at least six such: CH-750 (the original, along with the 701); ICP’s Savannah of Italy, SP30 from Russia, Sila from Serbia, and G1 from France. Even this list is not complete. G1 was reportedly modeled after yet another, the now-discontinued Alisport Puma. Clearly, this is a popular form of aircraft. Read G1 America’s  Mark said they estimate someone with average mechanical aptitude will need only 300 hours to assemble the kit. A customer who has built any kit previously could possibly assemble G1 in significantly less time, Mark believes.

Mark said they estimate someone with average mechanical aptitude will need only 300 hours to assemble the kit. A customer who has built any kit previously could possibly assemble G1 in significantly less time, Mark believes.

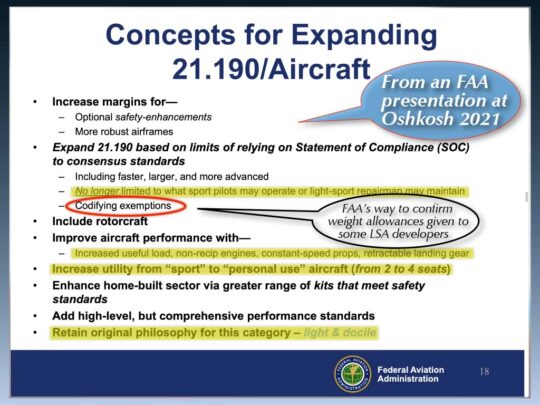

Since to my similar talk a year ago — when I introduced the then-recently-devised term of Light Personal Aircraft …which is now gone! — lots and lots of pilots have written wondering if this or that general aviation airplane could be included as a LSA. Here’s my response.

Since to my similar talk a year ago — when I introduced the then-recently-devised term of Light Personal Aircraft …which is now gone! — lots and lots of pilots have written wondering if this or that general aviation airplane could be included as a LSA. Here’s my response. So, how could a Sport Pilot be allowed to fly a larger aircraft, or possibly one with four seats, or one with retractable gear? All that is up to Flight Standards, the group that makes decisions about pilot privileges and flight operations. Unlike the aircraft certification department that is giving more work to industry (who might then chose methods they prefer), Flight Standards is unlikely to hand over any work to the industry.

So, how could a Sport Pilot be allowed to fly a larger aircraft, or possibly one with four seats, or one with retractable gear? All that is up to Flight Standards, the group that makes decisions about pilot privileges and flight operations. Unlike the aircraft certification department that is giving more work to industry (who might then chose methods they prefer), Flight Standards is unlikely to hand over any work to the industry. I flew

I flew

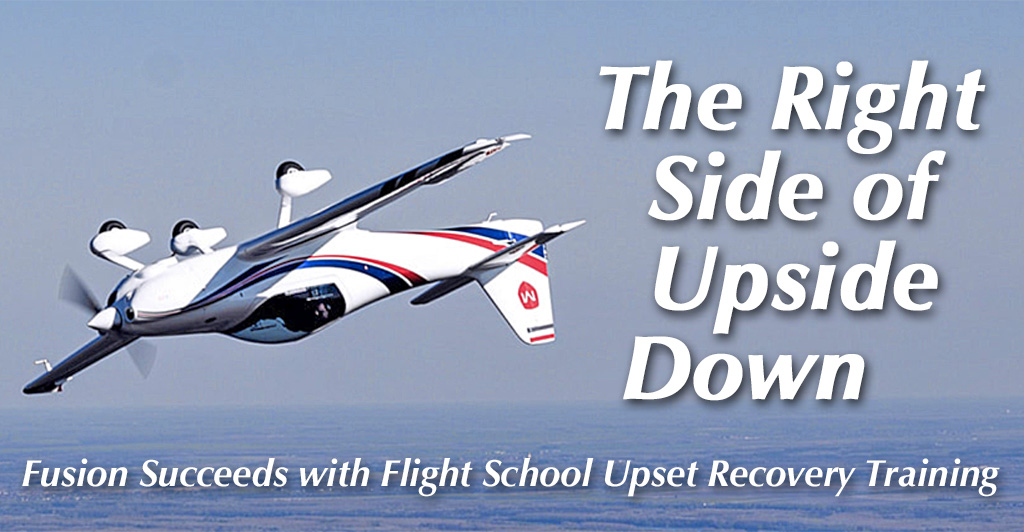

As head of Magnus Aircraft’s U.S. operation, Doma is an ideal candidate. He has worked in the factory in Hungary for some years, as head of communications and marketing. As the Hungarian company sought to pursue business in America, the leadership sent Doma to Texas to help Fusion 212 earn its SLSA Special Airworthiness Certificate.

As head of Magnus Aircraft’s U.S. operation, Doma is an ideal candidate. He has worked in the factory in Hungary for some years, as head of communications and marketing. As the Hungarian company sought to pursue business in America, the leadership sent Doma to Texas to help Fusion 212 earn its SLSA Special Airworthiness Certificate.

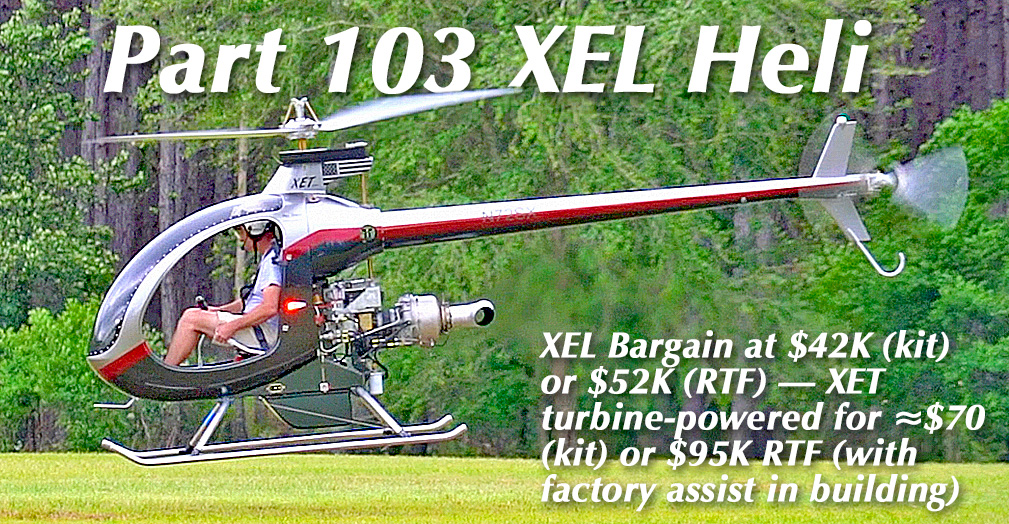

Those words almost don’t belong in the same sentence: “afford” and “helicopter.” Most pilots have little idea how much they cost because they’re seen as expensive and devilishly hard to fly. A Robinson R22, the company’s lowest cost two seater, starts at $325,000.

Those words almost don’t belong in the same sentence: “afford” and “helicopter.” Most pilots have little idea how much they cost because they’re seen as expensive and devilishly hard to fly. A Robinson R22, the company’s lowest cost two seater, starts at $325,000. The XE290 is equipped with a more powerful engine, additional fuel, and more instrumentation. Of course, you have to build this one but they can help at the factory.

The XE290 is equipped with a more powerful engine, additional fuel, and more instrumentation. Of course, you have to build this one but they can help at the factory. This simpler method is a key reason why not only are the XE helicopters well priced but why they have fewer repair problems and are significantly lighter in weight.

This simpler method is a key reason why not only are the XE helicopters well priced but why they have fewer repair problems and are significantly lighter in weight.

Composite FX personnel showed interest in looking into this opportunity and it is not unreasonable for FAA to at least consider these aircraft assuming appropriate ASTM standards can find acceptance (no helicopter standard has yet been proposed). XE safety does not pose a problem; Composite FX has delivered around 500 units and only two suffered serious accidents, according to the factory.

Composite FX personnel showed interest in looking into this opportunity and it is not unreasonable for FAA to at least consider these aircraft assuming appropriate ASTM standards can find acceptance (no helicopter standard has yet been proposed). XE safety does not pose a problem; Composite FX has delivered around 500 units and only two suffered serious accidents, according to the factory.

Having attended all of these Midwest events (but one, due to an approaching hurricane in my home state of Florida), I can tell you — and many pictures prove — that social distancing is easy at Mt. Vernon. These sector-specific shows have smaller crowds. You can easily approach a vendor and have a conversation without getting close, if you prefer.

Having attended all of these Midwest events (but one, due to an approaching hurricane in my home state of Florida), I can tell you — and many pictures prove — that social distancing is easy at Mt. Vernon. These sector-specific shows have smaller crowds. You can easily approach a vendor and have a conversation without getting close, if you prefer. “The shuttles (to and from hotels and restaurants in town, 15 minutes away) will begin with the first arrival.

“The shuttles (to and from hotels and restaurants in town, 15 minutes away) will begin with the first arrival.

Maybe I should clarify: I mean the on-site camera work plus the keeping track of what we’re doing next, handling a load of gear, planning the next day’s video stories, downloading huge video files each evening and placing them somewhere to be used later, and charging up everything you own as you sleep. While we’re shooting a video, Dave takes a director’s view of where we’re going and guides us along. He’s also very aircraft-savvy so if we lack a piece of information, he can often provide it. The show must go on, you know.

Maybe I should clarify: I mean the on-site camera work plus the keeping track of what we’re doing next, handling a load of gear, planning the next day’s video stories, downloading huge video files each evening and placing them somewhere to be used later, and charging up everything you own as you sleep. While we’re shooting a video, Dave takes a director’s view of where we’re going and guides us along. He’s also very aircraft-savvy so if we lack a piece of information, he can often provide it. The show must go on, you know.

AirVenture Oshkosh is arguably the most important aviation event in the world each year, bringing people together from all points on the compass… or, at least it usually does.

AirVenture Oshkosh is arguably the most important aviation event in the world each year, bringing people together from all points on the compass… or, at least it usually does. One objective of mine was achieved when a trusted, reliable source provided me with hard data about the state of the light aviation industry around the world. Most readers know I follow the

One objective of mine was achieved when a trusted, reliable source provided me with hard data about the state of the light aviation industry around the world. Most readers know I follow the

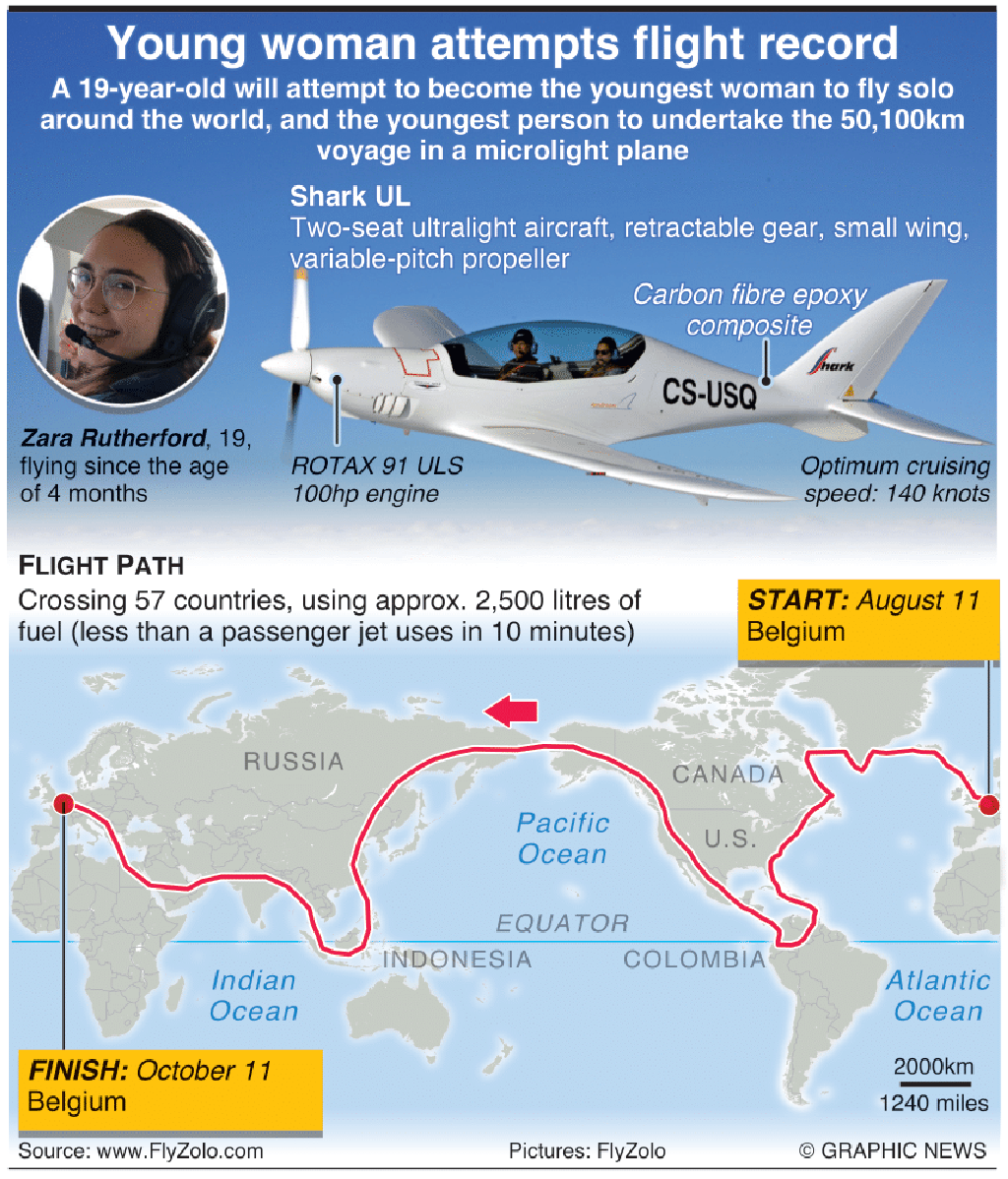

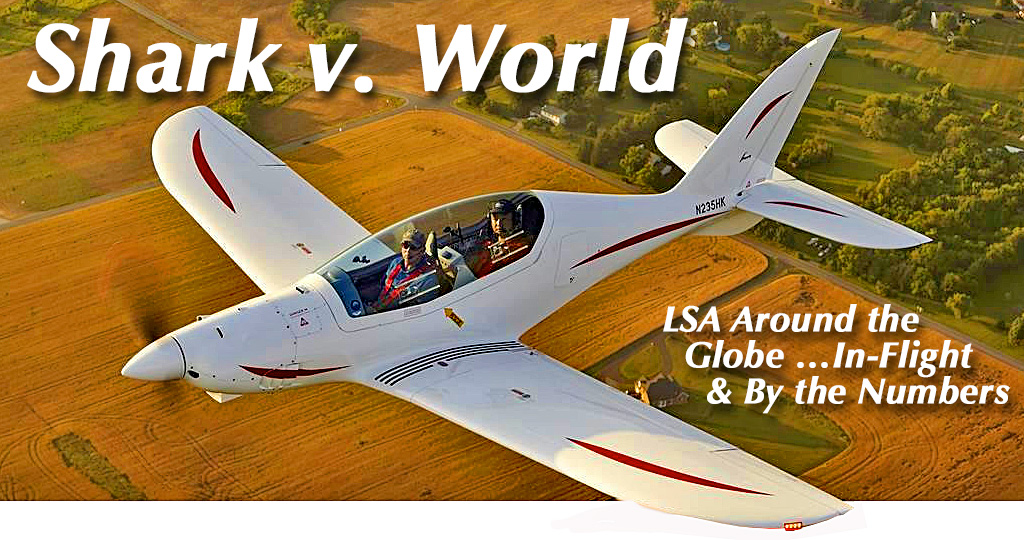

Zara has a good aviation foundation. She reports traveling in small planes since the age of six, skydiving at 11, and flying a plane at 14. After all that why not go for broke at 19? Ah, youth!

Zara has a good aviation foundation. She reports traveling in small planes since the age of six, skydiving at 11, and flying a plane at 14. After all that why not go for broke at 19? Ah, youth! The title isn’t new.

The title isn’t new. Through those years, a man I learned to deeply admire edited the publication. Many readers will recognize the name Dave Martin from earlier days. He had an impeccable reputation earned through thoroughness and fairness, capability and approachability. I could never slack off when preparing material for Dave. He could be a tough taskmaster but also acknowledged when a piece was good. My writing undoubtedly improved because of years of input he offered me. I so enjoyed working with him.

Through those years, a man I learned to deeply admire edited the publication. Many readers will recognize the name Dave Martin from earlier days. He had an impeccable reputation earned through thoroughness and fairness, capability and approachability. I could never slack off when preparing material for Dave. He could be a tough taskmaster but also acknowledged when a piece was good. My writing undoubtedly improved because of years of input he offered me. I so enjoyed working with him.

This is not a pace I heard at Sun ‘n Fun 2021, for example. That first show of the year was more tentative. People were still frightened by unrelenting news on TV and Sun ‘n Fun represented a first step back toward normal. Mind you, I considered the Lakeland show another big success; many others evidently decided by late July that the situation had improved enough for pilots to open their wallets.

This is not a pace I heard at Sun ‘n Fun 2021, for example. That first show of the year was more tentative. People were still frightened by unrelenting news on TV and Sun ‘n Fun represented a first step back toward normal. Mind you, I considered the Lakeland show another big success; many others evidently decided by late July that the situation had improved enough for pilots to open their wallets.

The company also has a virtual reality training system that can help familiarize new pilots. On whole, Norbert felt it was reasonable for a new pilot to fly and he said most pilots will become rather capable in just 10-20 hours.

The company also has a virtual reality training system that can help familiarize new pilots. On whole, Norbert felt it was reasonable for a new pilot to fly and he said most pilots will become rather capable in just 10-20 hours. The Mosquito derivative XE-series has been successful with more than 400 kits or fully-built 103 editions built (150 are Part 103 helicopters). The company is less sure about the number of delivered kits to get airborne as many have been sent overseas where it is difficult to track them but they believe more than 300 total units are flying.

The Mosquito derivative XE-series has been successful with more than 400 kits or fully-built 103 editions built (150 are Part 103 helicopters). The company is less sure about the number of delivered kits to get airborne as many have been sent overseas where it is difficult to track them but they believe more than 300 total units are flying. EAB Models

EAB Models

I recall when

I recall when  Fusion eNano

Fusion eNano I have a video in the works where Chip will explain this more fully and talk about its merits.

I have a video in the works where Chip will explain this more fully and talk about its merits. So Merlin doesn’t use electric power for main thrust but does make effective use of electric propulsion.

So Merlin doesn’t use electric power for main thrust but does make effective use of electric propulsion.

The magic of airshows and their ability to deliver in-person meetings showed their value yesterday at AirVenture Oshkosh. The following relates the story as best I could piece it together. Be advised this is not the final word on the subject. In fact, it is so fresh that changes are probable.

The magic of airshows and their ability to deliver in-person meetings showed their value yesterday at AirVenture Oshkosh. The following relates the story as best I could piece it together. Be advised this is not the final word on the subject. In fact, it is so fresh that changes are probable.

VASHON

VASHON And, speaking of area movements…

And, speaking of area movements…

BADLAND AIRCRAFT / F-SERIES

BADLAND AIRCRAFT / F-SERIES

HIPERLIGHT

HIPERLIGHT

CARLSON SPARROW

CARLSON SPARROW

Indeed, as light aviation enthusiasts prepare for the coming Mosaic regulation that will dramatically alter the landscape, a clearer dividing line is revealing itself. Many light aircraft have embraced Rotax’s four stroke engines, overwhelmingly their 9-series models including carbureted 912 ULS, fuel-injected 912iS, turbocharged 914, and the newest 915iS.

Indeed, as light aviation enthusiasts prepare for the coming Mosaic regulation that will dramatically alter the landscape, a clearer dividing line is revealing itself. Many light aircraft have embraced Rotax’s four stroke engines, overwhelmingly their 9-series models including carbureted 912 ULS, fuel-injected 912iS, turbocharged 914, and the newest 915iS.