Here is more news from AirVenture 2015, coming from Tuesday, Day Two.

The Light Aircraft Manufacturers Association gave a press conference to a full house. LAMA enjoyed a terrific opening day in its mission of advocacy for Light-Sport, light kit, and ultralight aircraft. Partnered with the U.S. Ultralight Association (USUA), LAMA participated in two very productive meetings, one with EAA’s advocacy experts and another with several key FAA personnel. USUA’s Roy Beisswenger and I hope for good things to follow but felt highly energized that we moved closer to some goals we believe can truly help the light aircraft industry and its pilots.

That was the “business” portion of LAMA’s press conference, but we kept it brief as we had a more meaningful message to deliver.

LAMA has presented its President’s Award for 24 years running to an outstanding individual whose work benefitted the light aircraft sector. Announcing this year’s recipient was one of those bittersweet moments.

Here is more news from AirVenture 2015, coming from Tuesday, Day Two.

The Light Aircraft Manufacturers Association gave a press conference to a full house. LAMA enjoyed a terrific opening day in its mission of advocacy for Light-Sport, light kit, and ultralight aircraft. Partnered with the U.S. Ultralight Association (USUA), LAMA participated in two very productive meetings, one with EAA’s advocacy experts and another with several key FAA personnel. USUA’s Roy Beisswenger and I hope for good things to follow but felt highly energized that we moved closer to some goals we believe can truly help the light aircraft industry and its pilots.

That was the “business” portion of LAMA’s press conference, but we kept it brief as we had a more meaningful message to deliver.

LAMA has presented its President’s Award for 24 years running to an outstanding individual whose work benefitted the light aircraft sector. Announcing this year’s recipient was one of those bittersweet moments.Day Two: LAMA Award and New Rotax Engine

Here is more news from AirVenture 2015, coming from Tuesday, Day Two.

The Light Aircraft Manufacturers Association gave a press conference to a full house. LAMA enjoyed a terrific opening day in its mission of advocacy for Light-Sport, light kit, and ultralight aircraft. Partnered with the U.S. Ultralight Association (USUA), LAMA participated in two very productive meetings, one with EAA’s advocacy experts and another with several key FAA personnel. USUA’s Roy Beisswenger and I hope for good things to follow but felt highly energized that we moved closer to some goals we believe can truly help the light aircraft industry and its pilots.

That was the “business” portion of LAMA’s press conference, but we kept it brief as we had a more meaningful message to deliver.

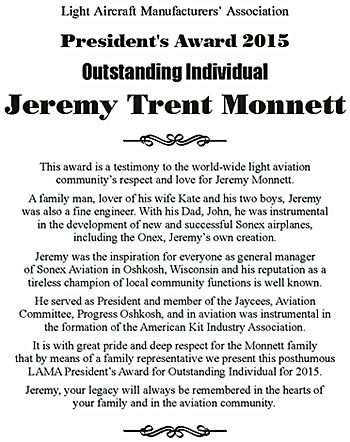

LAMA has presented its President’s Award for 24 years running to an outstanding individual whose work benefitted the light aircraft sector. Announcing this year’s recipient was one of those bittersweet moments. LAMA Founder Larry Burke solicited votes from about 800 members of the LSA business community and the convincing winner was Jeremy Monnett, the young business leader who was managing the company his father built (Sonex) when he was tragically killed in an accident.

Jeremy’s father and mother John and Betty supported Jeremy’s wife Kate and one of their sons along with many of the Sonex team as the family received the award in a heartwarming, emotionally-charged presentation.

I was honored and moved to present this award and to deliver some remarks prepared by Larry Burke because last-minute changes prevented him from attending this year’s AirVenture 2015 as originally planned. All of us in the aviation community offer our sincerest condolences to the Monnett family and Sonex team for the loss of this fine young aviator.

Yet, as Jeremy would have preferred, aviation must continue to advance and it did with a presentation from Rotax Aircraft Engines.

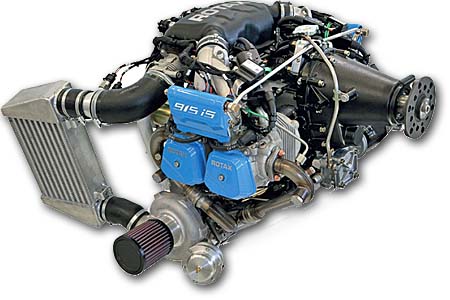

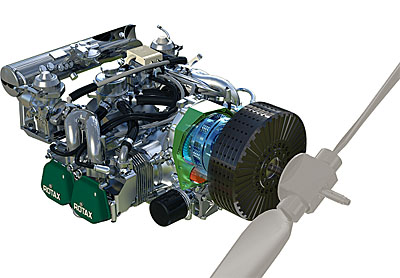

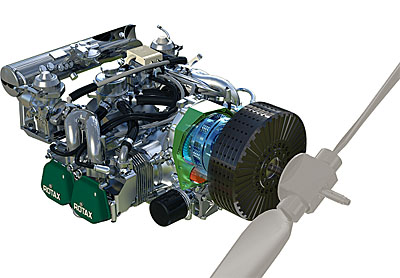

Lead by their capable Marc Becker Rotax BRP officials packed the press conference room to capacity for the rollout of their brand new Rotax 915 engine. This company is widely known for their 9-series engines that just got a bit bigger and a third more powerful.

Marc related many interesting facts, among them the 50 million hours logged on Rotax aviation powerplants, with that enormous dataset growing by five million more hours every year. Clearly one of the most successful companies in aviation, Rotax is going even further with their 135-horsepower (100 kW) Rotax 915.

The new 915 is a fuel injected engine also using a turbocharger so it can maintain power up to 15,000 feet, Marc announced. In a Q&A session where many quizzed the BRP team, Marc said the 915 has already logged 2,000 hours on the dyno tester. The engine will continue to go through Rotax’s typically thorough testing and will reach the market in the last half of 2017.

In addition to their own testing, Rotax is careful to work with their large group of OEMs (Original Equipment Manufacturers) to assure the mounting and general installation of their engine is as solid and finished as their engine design and manufacturing. In fact, it is this high standard of care that ensures customers have great experiences with Rotax engines.

In our LAMA meetings mentioned at the start of this article, we are working to ease the regulation logjam that prevents gyroplanes from being Special fully-manufactured LSA in the USA. In discussions, we often relate that Rotax reports selling more 912 engines to gyroplanes than any other aircraft segment because overseas, gyros are selling strongly, lead by the AutoGyro company. So perhaps it will surprise few that AutoGyro USA already had a 915-equipped model in their space at Oshkosh.

In the spirited Q&A session, Rotax officials were asked about the 915 on light helicopters, which often need more oomph. Plant manager Thomas Uhr confirmed such use and I can imagine LSA seaplanes like Icon and MVP may also move to the more potent engine as they also benefit from strength during the critical water launch phase.

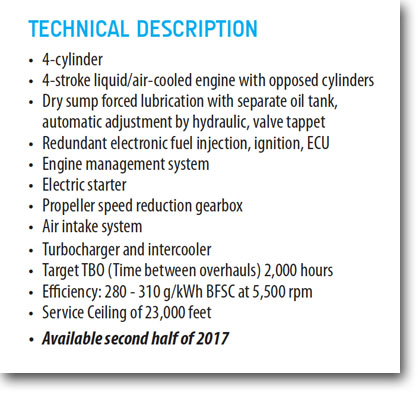

The nearby chart shows more facts about Rotax’s new 915 engine and you can investigate further at this link.

Stay tuned … more Oshkosh light aircraft news to follow!

Here is more news from AirVenture 2015, coming from Tuesday, Day Two.

The Light Aircraft Manufacturers Association gave a press conference to a full house. LAMA enjoyed a terrific opening day in its mission of advocacy for Light-Sport, light kit, and ultralight aircraft. Partnered with the U.S. Ultralight Association (USUA), LAMA participated in two very productive meetings, one with EAA’s advocacy experts and another with several key FAA personnel. USUA’s Roy Beisswenger and I hope for good things to follow but felt highly energized that we moved closer to some goals we believe can truly help the light aircraft industry and its pilots.

That was the “business” portion of LAMA’s press conference, but we kept it brief as we had a more meaningful message to deliver.

LAMA has presented its President’s Award for 24 years running to an outstanding individual whose work benefitted the light aircraft sector. Announcing this year’s recipient was one of those bittersweet moments.

Here is more news from AirVenture 2015, coming from Tuesday, Day Two.

The Light Aircraft Manufacturers Association gave a press conference to a full house. LAMA enjoyed a terrific opening day in its mission of advocacy for Light-Sport, light kit, and ultralight aircraft. Partnered with the U.S. Ultralight Association (USUA), LAMA participated in two very productive meetings, one with EAA’s advocacy experts and another with several key FAA personnel. USUA’s Roy Beisswenger and I hope for good things to follow but felt highly energized that we moved closer to some goals we believe can truly help the light aircraft industry and its pilots.

That was the “business” portion of LAMA’s press conference, but we kept it brief as we had a more meaningful message to deliver.

LAMA has presented its President’s Award for 24 years running to an outstanding individual whose work benefitted the light aircraft sector. Announcing this year’s recipient was one of those bittersweet moments.

With our friends at the prestigious Flying magazine putting

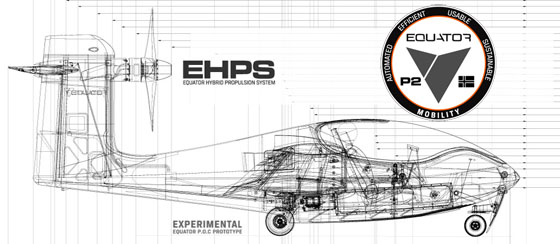

With our friends at the prestigious Flying magazine putting  Israel’s Ashot Ashkelon, Italian hybrid propulsion specialist Efesto joined with Italian light airplane manufacturer

Israel’s Ashot Ashkelon, Italian hybrid propulsion specialist Efesto joined with Italian light airplane manufacturer  CFM Air develops and manufactures light planes such as the

CFM Air develops and manufactures light planes such as the  However, developers seem primarily focused on emergency use of HPS saying it adds, “a significant safety element in case of [primary engine] failure by providing extra flight time using the electric motor, also as a replacement for the Safety Parachute.” Based on many years working with BRS Parachutes, I am certain HPS will not always “replace” the airframe parachute, for example, after a mid-air collision. Nonetheless, using HPS to solve engine failure or fuel starvation would be much less exciting than firing a ballistic parachute.

However, developers seem primarily focused on emergency use of HPS saying it adds, “a significant safety element in case of [primary engine] failure by providing extra flight time using the electric motor, also as a replacement for the Safety Parachute.” Based on many years working with BRS Parachutes, I am certain HPS will not always “replace” the airframe parachute, for example, after a mid-air collision. Nonetheless, using HPS to solve engine failure or fuel starvation would be much less exciting than firing a ballistic parachute.

Some people, myself included, love soaring flight. As the following article from Dave Unwin explains, to use his words, “Soaring flight exercises a fascination that is both difficult to explain and hard to resist, sometimes called ‘three-dimensional sailing.’ Flying a heavier-than-air machine for several hours and hundreds of miles by using the atmosphere as the fuel possesses an undeniable attraction.” As he further explained in a longer article, the downside is getting airborne for soaring flight. Various alternatives have been explored. Some were reasonable; others were too marginal to be enjoyed. In the following piece Dave tells about a new aircraft that might solve this problem, one that can fit England’s innovative SSDR 300 (kilogram) category.

Some people, myself included, love soaring flight. As the following article from Dave Unwin explains, to use his words, “Soaring flight exercises a fascination that is both difficult to explain and hard to resist, sometimes called ‘three-dimensional sailing.’ Flying a heavier-than-air machine for several hours and hundreds of miles by using the atmosphere as the fuel possesses an undeniable attraction.” As he further explained in a longer article, the downside is getting airborne for soaring flight. Various alternatives have been explored. Some were reasonable; others were too marginal to be enjoyed. In the following piece Dave tells about a new aircraft that might solve this problem, one that can fit England’s innovative SSDR 300 (kilogram) category.  When I heard that

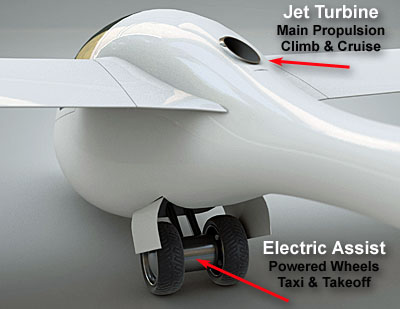

When I heard that  The Titan jet engine is fixed internally behind the cockpit and features an automatic open/close intake scoop. This very neat little turbojet is less 40 centimeters (16 inches) long and weighs an astonishing 3.7 kilograms (8 pounds), yet produces a creditable 88 pounds of thrust. This should be enough to produce reasonable climb rates at around 50 knots, while the 9-gallon fuel tank should last for several further climbs.

The Titan jet engine is fixed internally behind the cockpit and features an automatic open/close intake scoop. This very neat little turbojet is less 40 centimeters (16 inches) long and weighs an astonishing 3.7 kilograms (8 pounds), yet produces a creditable 88 pounds of thrust. This should be enough to produce reasonable climb rates at around 50 knots, while the 9-gallon fuel tank should last for several further climbs. Trade-offs exist, of course. By definition GloW is very light so although the projected best L/D is expected to be mid-30s, this will be achieved at relatively low speed. However, the same is true for the minimum sink, so GloW should climb very well indeed.

Trade-offs exist, of course. By definition GloW is very light so although the projected best L/D is expected to be mid-30s, this will be achieved at relatively low speed. However, the same is true for the minimum sink, so GloW should climb very well indeed.

A few years back at Aero 2009,

A few years back at Aero 2009,  Researchers at Universidad Carlos III de Madrid (UC3M) and the

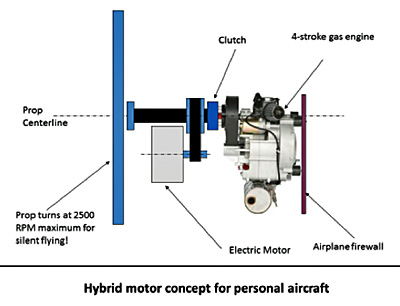

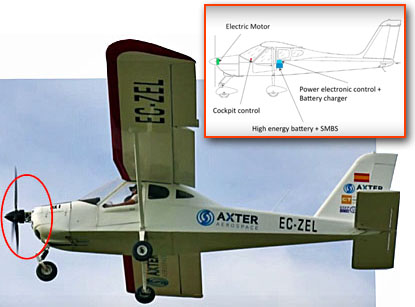

Researchers at Universidad Carlos III de Madrid (UC3M) and the  The idea is to equip the plane with an electric engine mounted aft of the propeller but outside the engine compartment (at least in the test article). Such an installation suggests this could be an add-on to existing aircraft once the company decides to commercialize their work.

The idea is to equip the plane with an electric engine mounted aft of the propeller but outside the engine compartment (at least in the test article). Such an installation suggests this could be an add-on to existing aircraft once the company decides to commercialize their work. “We maximize the capacity of the battery in generating movement with the electric engine, and we have found that we can also use the system as a hybrid for light aircraft; the pilot can activate it when she wants, adding up to 40 horsepower for takeoff or whatever is needed,” said Daniel Cristobal, now also with Axter Aerospace and an alumnus of the UC3M. “This way, it could be used as if it were an electric turbo to increase the power of the aircraft in certain maneuvers.”

“We maximize the capacity of the battery in generating movement with the electric engine, and we have found that we can also use the system as a hybrid for light aircraft; the pilot can activate it when she wants, adding up to 40 horsepower for takeoff or whatever is needed,” said Daniel Cristobal, now also with Axter Aerospace and an alumnus of the UC3M. “This way, it could be used as if it were an electric turbo to increase the power of the aircraft in certain maneuvers.”

Let’s move right to an important point. BushCat is most interesting aircraft with unique features of interest to many and you are much more likely to afford the South African airplane with its 2015 U.S. price of $65,000. That figure covers the

Let’s move right to an important point. BushCat is most interesting aircraft with unique features of interest to many and you are much more likely to afford the South African airplane with its 2015 U.S. price of $65,000. That figure covers the  Quite significantly, BushCat’s useful load now elevates to 617 pounds with 25 gallons of fuel. That means payload with full fuel is 465 pounds, which allows two 200-hundred pound occupants plus 65 pounds of cargo or other airborne gear. So, a very modest price — about what many expected eleven years ago when the SP/LSA rule was announced, all the more impressive as the time value of money has changed considerable in that period — and you get more utility for the dollars you spend. I’d call that win-win.

Quite significantly, BushCat’s useful load now elevates to 617 pounds with 25 gallons of fuel. That means payload with full fuel is 465 pounds, which allows two 200-hundred pound occupants plus 65 pounds of cargo or other airborne gear. So, a very modest price — about what many expected eleven years ago when the SP/LSA rule was announced, all the more impressive as the time value of money has changed considerable in that period — and you get more utility for the dollars you spend. I’d call that win-win. A couple years ago, one of the bigger changes SkyReach engineers made to BushCat was a move from a more complicated braced undercarriage to a sprung undercarriage. The new design uses a slab-style aluminum spring gear that SkyReach says provides a more accommodating load dampening resulting in softer off-airport landings. This airplane does duty in South Africa fighting animal poaching and can handle rough-field operation. It also features removable doors, which may work well for the anti-poaching task but also appeals to those of use that like open cockpit on warm summer days.

A couple years ago, one of the bigger changes SkyReach engineers made to BushCat was a move from a more complicated braced undercarriage to a sprung undercarriage. The new design uses a slab-style aluminum spring gear that SkyReach says provides a more accommodating load dampening resulting in softer off-airport landings. This airplane does duty in South Africa fighting animal poaching and can handle rough-field operation. It also features removable doors, which may work well for the anti-poaching task but also appeals to those of use that like open cockpit on warm summer days. In closing this piece, I want to pay tribute to two light aviation kit builders. In the USA, the loss of Jeremy Monnett stunned many as he and assembly mechanic Mike Clark were killed June 2nd in an aircraft accident near the company’s headquarters in Oshkosh, Wisconsin. Jeremy successfully lead the Sonex company in recent years and used a degree in mechanical engineering to create a design of his own, the single-seat, folding-wing Onex (“One-Ex”) introduced in 2011.

In closing this piece, I want to pay tribute to two light aviation kit builders. In the USA, the loss of Jeremy Monnett stunned many as he and assembly mechanic Mike Clark were killed June 2nd in an aircraft accident near the company’s headquarters in Oshkosh, Wisconsin. Jeremy successfully lead the Sonex company in recent years and used a degree in mechanical engineering to create a design of his own, the single-seat, folding-wing Onex (“One-Ex”) introduced in 2011.

Date #1 was the time when FAA announced

Date #1 was the time when FAA announced  FAA recently came out with

FAA recently came out with  “I was personally astounded. The consultation was very interesting. The LAA who had supported the old 115 kilogram rule (253 pounds, so almost identical to the U.S. Part 103 weight) suddenly came out against the rule asking for a wing loading restriction to be added. I guess they realized that it was a big threat to their monopoly. Even at the consultation stage &mdash after the proposals had been published &mdash the consensus was that eventually the wing loading restriction would be added. The CAA stood firm and the rule was passed without modification. It required an Act of Parliament to become law but eventually it was done.”

“I was personally astounded. The consultation was very interesting. The LAA who had supported the old 115 kilogram rule (253 pounds, so almost identical to the U.S. Part 103 weight) suddenly came out against the rule asking for a wing loading restriction to be added. I guess they realized that it was a big threat to their monopoly. Even at the consultation stage &mdash after the proposals had been published &mdash the consensus was that eventually the wing loading restriction would be added. The CAA stood firm and the rule was passed without modification. It required an Act of Parliament to become law but eventually it was done.” So, what does the CAA SSDR 300 look like?

So, what does the CAA SSDR 300 look like?