Updated September 26, 2018 — This article has been updated to include more producers. See at bottom. —DJ

Over many years, you have found LSA market share information on this website. Many have found this of interest …from businesses learning more about their market; to customers doing careful investigation before paying tens or hundreds of thousands of dollars for a new aircraft; to government fulfilling its task of regulating industry; to insurance companies assessing risk of providing their product; and many other actors in the blockbuster movie that is light, recreational aviation.

I will have more to say about the broader LSA market share reports below but now I want to present the best information I have seen for Light-Sport Aircraft Gyroplanes.

…uh, except for one problem. No such aircraft category exists, SLSA gyroplanes, that is.

FAA has denied fully-built Special LSA status to rotary winged aircraft such as gyroplanes.

Updated September 26, 2018 — This article has been updated to include more producers. See at bottom. —DJ

Over many years, you have found LSA market share information on this website. Many have found this of interest …from businesses learning more about their market; to customers doing careful investigation before paying tens or hundreds of thousands of dollars for a new aircraft; to government fulfilling its task of regulating industry; to insurance companies assessing risk of providing their product; and many other actors in the blockbuster movie that is light, recreational aviation.

I will have more to say about the broader LSA market share reports below but now I want to present the best information I have seen for Light-Sport Aircraft Gyroplanes.

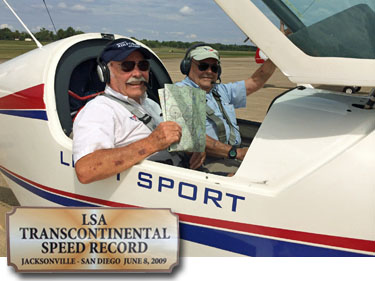

…uh, except for one problem. No such aircraft category exists, SLSA gyroplanes, that is.

FAA has denied fully-built Special LSA status to rotary winged aircraft such as gyroplanes.Gyroplanes Are Big Overseas — First Market Share Info for the USA

Updated September 26, 2018 — This article has been updated to include more producers. See at bottom. —DJ

I will have more to say about the broader LSA market share reports below but now I want to present the best information I have seen for Light-Sport Aircraft Gyroplanes.

…uh, except for one problem. No such aircraft category exists, SLSA gyroplanes, that is.

SilverLight Aviation’s AR-1; photo by Amy Saunders

FAA has denied fully-built Special LSA status to rotary winged aircraft such as gyroplanes. LAMA thought this was on track for a solution as recently as two months ago (see report), but today, the matter is back in doubt, truly a shame as these aircraft are thriving around the world.

Rotax has reported for some time that they sell more 9-series engines to gyroplanes as a specific category than to other groups. Indeed, sellers like Germany’s AutoGyro have more than 2,500 units flying.

FAA’s rotorcraft personnel are living in the past, remembering the problems of early machines like the Bensen Gyrocopter. Before training and before design evolution, those aircraft did have a undesirable safety record. However, that has been remedied… long ago, actually.

In his article, he wrote, “[Along with better training] the other change since those days is the large horizontal stabilizer, mounted well aft. Some machines were prone to PIO, pilot-induced oscillations in pitch. The pilot would chase the oscillations, only making them worse until the gyro did a fatal bunt over. The large tail that Magni invented – as is used on all modern gyros – has fixed that.”

Welcoming Steve Beste

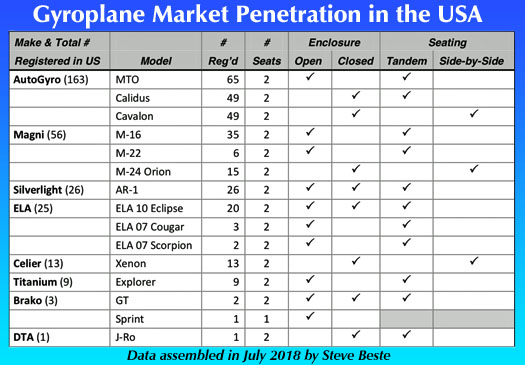

“I’m a retired computer guy and trike pilot who loves databases,” Steve told me. He used his special set of skills to download FAA’s aircraft registration database to compile statistics on gyroplane registrations, focused on the new European-style gyroplanes.

A new American manufacturer, SilverLight Aviation, has quickly tied Spanish producer ELA for third at 8% with 26 aircraft registered for each. After that it trails off more quickly as Steve’s chart shows. More details about other brands will be chronicled in an article to follow.

For 2018 through July 23rd, Magni shows its strength by slightly beating AutoGyro U.S. registrations. As always, note that confirmed sales and registrations may not match precisely. In addition, much more of 2018 remains. In slightly more than half a year, gyroplanes registered 58 aircraft putting them on track to exceed 100 for the year. To offer perspective, this figure is approaching half as many as SLSA fixed wing registrations in recent full years.

Magni Gyro’s M24 Orion

So far this year, Magni has 15 registrations to AutoGyro’s 14 for 26% and 24% shares totaling half of total U.S. gyroplane registrations. SilverLight has registered 8 aircraft in 2018 for a 14% yearly share of 2018 to date.

A less well recognized U.S. producer, Tango, is having a respectable year, with 9 registrations accounting for 16% in 2018 so far. Tango is trailed by ELA with 6 registrations (10%), Australia’s Titanium and Italy’s Brako tied at 3 for 5% each. One interesting point: only Tango and Brako offer a single place gyroplane; all others are two place machines.

Much More Data to Follow!

Steve Beste and I have been discussing him providing database research to allow this website to continue providing LSA Market Share Info. Many visitors have written to ask; indeed, we are way behind on this effort.

ELA’s 10-Eclipse

The delay is ending. After Steve gets time to study the previous work and methods, he has proposed some wonderful improvements.

About the special skills he can offer, Steve wrote, “I’m a retired computer guy and trike pilot who loves databases.” Well, that certainly sounds perfect to me.

“I’m also the president of Flying Club 1, which was the original USUA Chapter 1,” Steve added. “Regarding the FAA database, I’d very much like to reach beyond just [fixed wing] airplanes, partly because I’m a trike pilot, myself. I think that’s entirely possible.”

Given this background, his obvious enthusiasm for this work, and the keen interest of many in light aviation, I am exceedingly pleased to welcome Steve to this website.

However, we hope that will now change and our market share reporting will be more inclusive. Hurray!

He added, “There’s no end of that kind of thing …just so we know the limitations on this exercise. But with that understanding, I love this kind of thing, I have the skills to do it, and would be honored to support your good work for the sport.” All such reporting will be available on the home page when fresh and catalogued on its own space found by this link.

Wonderful, simply wonderful! Please welcome Steve Beste as a new contributor to ByDanJohnson.com!

UPDATE September 26, 2018 — In the article above, I inadvertently suggested SilverLight and their American Ranger gyroplane was the first or only U.S. producer of such aircraft. That is not what I intended but some readers viewed it that way. Allow me to bring your attention to two other producers.

Sport Copter & Rotor Flight Dynamics

Based in Oregon, Sport Copter is a long established, second-generation family business started in 1958. Chuck Vanek was one of the early pioneers of gyroplane design and development beginning his work in 1957.

An airshow performer, Jim said he wrote the parameters and guidelines for gyroplane looping for the FAA in 1998 after performing the world’s first loop in a conventional gyroplane, in 1997. The company’s website reports, “He is the only gyro pilot in the world that holds an International Council of Air Shows card for gyroplane looping and rolling.” Don’t even think about trying this yourself, however.

Rotor Flight Dynamics, founded and run by Ernie Boyette, produces a two place and single variations of their Dominator line. Sold as kit aircraft, the two-place model can be powered by Hirth four-cylinder engines, Subaru/AutoFlight EA-81, or the 115-horsepower Rotax 914 Turbo.

As with all the modern gyroplanes, Rotor Flight uses a substantial tailplane. “The Dominator [series of one and two-place machines] incorporate the Tall Tail design for stability.” Asked how their product differs, the company’s website states, “What makes the Dominator so unique is its high profile design. It sits up very high off the ground.”

Updated September 26, 2018 — This article has been updated to include more producers. See at bottom. —DJ

Over many years, you have found LSA market share information on this website. Many have found this of interest …from businesses learning more about their market; to customers doing careful investigation before paying tens or hundreds of thousands of dollars for a new aircraft; to government fulfilling its task of regulating industry; to insurance companies assessing risk of providing their product; and many other actors in the blockbuster movie that is light, recreational aviation.

I will have more to say about the broader LSA market share reports below but now I want to present the best information I have seen for Light-Sport Aircraft Gyroplanes.

…uh, except for one problem. No such aircraft category exists, SLSA gyroplanes, that is.

FAA has denied fully-built Special LSA status to rotary winged aircraft such as gyroplanes.

Updated September 26, 2018 — This article has been updated to include more producers. See at bottom. —DJ

Over many years, you have found LSA market share information on this website. Many have found this of interest …from businesses learning more about their market; to customers doing careful investigation before paying tens or hundreds of thousands of dollars for a new aircraft; to government fulfilling its task of regulating industry; to insurance companies assessing risk of providing their product; and many other actors in the blockbuster movie that is light, recreational aviation.

I will have more to say about the broader LSA market share reports below but now I want to present the best information I have seen for Light-Sport Aircraft Gyroplanes.

…uh, except for one problem. No such aircraft category exists, SLSA gyroplanes, that is.

FAA has denied fully-built Special LSA status to rotary winged aircraft such as gyroplanes.

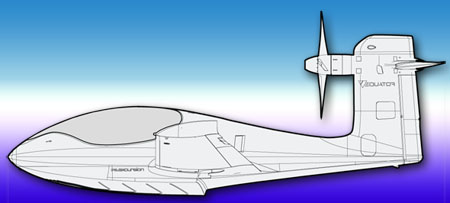

LSA seaplanes have provided some of the most interesting new developments in aviation. Perhaps interest stems from the vast numbers of landable waterways compared to runways. Perhaps it’s the versatility of amphibians. Maybe people are simple drawn by the good looks or unique qualities of entries.

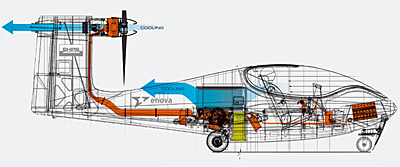

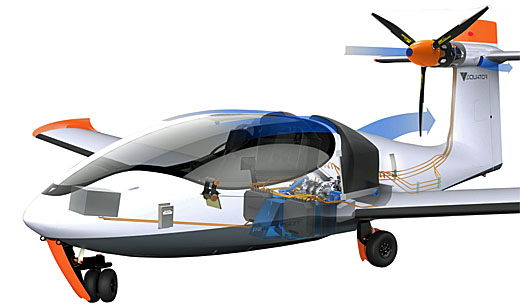

LSA seaplanes have provided some of the most interesting new developments in aviation. Perhaps interest stems from the vast numbers of landable waterways compared to runways. Perhaps it’s the versatility of amphibians. Maybe people are simple drawn by the good looks or unique qualities of entries. Part of the innovation Tomas introduced is a novel hybrid propulsion system to provide range, fuel efficiency and redundancy with all the benefits of electric power. With a purpose-designed control management system, the total pilot workload is reduced and higher levels of security are achieved, he believes.

Part of the innovation Tomas introduced is a novel hybrid propulsion system to provide range, fuel efficiency and redundancy with all the benefits of electric power. With a purpose-designed control management system, the total pilot workload is reduced and higher levels of security are achieved, he believes. Further innovation is a fly-by-wire rudder and drive-by-wire nosewheel. “Both are experimental technologies, Tomas explained, “that we believe may make it simpler for the prospective owner and pilot to learn how to fly. No more hand and foot coordination, here you can put your feet up high and use your hands only for all control inputs.”

Further innovation is a fly-by-wire rudder and drive-by-wire nosewheel. “Both are experimental technologies, Tomas explained, “that we believe may make it simpler for the prospective owner and pilot to learn how to fly. No more hand and foot coordination, here you can put your feet up high and use your hands only for all control inputs.” P2 Xcursion’s thrust is provided by an unusual aviation powerplant involving three elements: a motor spinning the prop; an electric generator supplying the motor and batteries; and an internal combustion engine powering the generator. At this time, P2 has both a test and boost battery plus it has the required electronic control unit (ECU).

P2 Xcursion’s thrust is provided by an unusual aviation powerplant involving three elements: a motor spinning the prop; an electric generator supplying the motor and batteries; and an internal combustion engine powering the generator. At this time, P2 has both a test and boost battery plus it has the required electronic control unit (ECU).

As a sum, the three elements weigh 233 pounds, roughly the weight of a legacy 100 horsepower aviation powerplant.

As a sum, the three elements weigh 233 pounds, roughly the weight of a legacy 100 horsepower aviation powerplant. Many years later, Equator’s P2 Xcursion first took flight in spring of 2018.

Many years later, Equator’s P2 Xcursion first took flight in spring of 2018.

Recently, seaplane enthusiast and businessman Paul Richards informed us of a move for a leading producer of floats for light aviation: Clamar.

Recently, seaplane enthusiast and businessman Paul Richards informed us of a move for a leading producer of floats for light aviation: Clamar. “Clamar’s new manufacturing facility will leverage a recently commissioned, advanced composites manufacturing center which includes an environmentally controlled layup room, high temperature processing oven, paint booth and advanced machining suite,” said Paul.

“Clamar’s new manufacturing facility will leverage a recently commissioned, advanced composites manufacturing center which includes an environmentally controlled layup room, high temperature processing oven, paint booth and advanced machining suite,” said Paul.

This article was

This article was

Vendors in attendance logged steady demo flights to prospective customers.

Vendors in attendance logged steady demo flights to prospective customers.

Airport manager Chris Collins forwarded more photos of the ceremony dedicating the SW21 Jet to the Mt. Vernon airport. Of the one with Jon Hansen reverently touching the main support for the aircraft he donated to the airport, Chris said, “I love this shot!”

Airport manager Chris Collins forwarded more photos of the ceremony dedicating the SW21 Jet to the Mt. Vernon airport. Of the one with Jon Hansen reverently touching the main support for the aircraft he donated to the airport, Chris said, “I love this shot!”

Many pilots expect the first appearance of a new model at the biggest airshows, but here’s one of those times when the sector-specific shows win. It’s all about timing and the new Aeroprakt A32 just won it’s SLSA approval (#147 on our

Many pilots expect the first appearance of a new model at the biggest airshows, but here’s one of those times when the sector-specific shows win. It’s all about timing and the new Aeroprakt A32 just won it’s SLSA approval (#147 on our  First blush: This is a great flying airplane, reflecting Aeroprakt’s experience producing more than 1,000 of the predecessor

First blush: This is a great flying airplane, reflecting Aeroprakt’s experience producing more than 1,000 of the predecessor  When deploying or retracting flaps, the pitch change is very minor. True, two notches is only 20° of flaps but deploying them made quite an aerodynamic change, just not a pitch change. On one landing I made with no flaps, I had to raise the nose significantly high to put A32 on the ground.

When deploying or retracting flaps, the pitch change is very minor. True, two notches is only 20° of flaps but deploying them made quite an aerodynamic change, just not a pitch change. On one landing I made with no flaps, I had to raise the nose significantly high to put A32 on the ground. A32 uses the identical wing from A22 from the fuselage root out. However, the many clean-ups of the fuselage — and they are many, which you will see more fully in the Video Pilot Report to follow after editing — make the new model more efficient. A pilot literally has to work at getting it back on the ground …and that’s a good thing.

A32 uses the identical wing from A22 from the fuselage root out. However, the many clean-ups of the fuselage — and they are many, which you will see more fully in the Video Pilot Report to follow after editing — make the new model more efficient. A pilot literally has to work at getting it back on the ground …and that’s a good thing. Takeoff and landing has been quoted at “under 100 meters” (300 feet) and I believe it. No question it was short, assuming, of course, decent technique.

Takeoff and landing has been quoted at “under 100 meters” (300 feet) and I believe it. No question it was short, assuming, of course, decent technique.

The biggest airshows in recreational aviation are history for 2018. I refer to

The biggest airshows in recreational aviation are history for 2018. I refer to  The sector specific shows are much smaller. That’s a good thing.

The sector specific shows are much smaller. That’s a good thing.

In between and up next:

In between and up next:  We start in September, pop up two months later in Florida, kick off the new year two months later in central Florida, and anticipate spring a month later in Arizona. In all, I’d call this an active schedule serving much of the recreational flying community. I’d hope you could make at least a couple of these if not all four.

We start in September, pop up two months later in Florida, kick off the new year two months later in central Florida, and anticipate spring a month later in Arizona. In all, I’d call this an active schedule serving much of the recreational flying community. I’d hope you could make at least a couple of these if not all four.

American producers were the kings of kits, an effort that calls for good assembly instructions and technical support plus groups that can help each other. These two activities represent night and day differences.

American producers were the kings of kits, an effort that calls for good assembly instructions and technical support plus groups that can help each other. These two activities represent night and day differences. As many readers know, nearby Synergy Air was Van’s assembly partner for several years. “[They have] done a tremendous job for Van’s and our customers,” stated Van’s. Synergy Air will continue to work with Van’s but will return to concentrate on builder-assist activities.

As many readers know, nearby Synergy Air was Van’s assembly partner for several years. “[They have] done a tremendous job for Van’s and our customers,” stated Van’s. Synergy Air will continue to work with Van’s but will return to concentrate on builder-assist activities. The natural evolution and success of both businesses has brought us to where we are today. Synergy has become even more focused on the business of assisting Van’s Aircraft’s customers in building their RV airplanes. As the SLSA program has matured, Van’s has expanded its workforce and capabilities to include marketing and aircraft construction. This change represents the next logical step in both companies’ successful business growth.

The natural evolution and success of both businesses has brought us to where we are today. Synergy has become even more focused on the business of assisting Van’s Aircraft’s customers in building their RV airplanes. As the SLSA program has matured, Van’s has expanded its workforce and capabilities to include marketing and aircraft construction. This change represents the next logical step in both companies’ successful business growth. You can and should expect excellent quality from a business that continuously strives to improve its products and services. Van’s approach is to delivering the highest quality products. Our aircraft assembly and delivery department — a dedicated team focused on just that portion of our business — is staffed by experts with years of RV-12 building experience. Van’s will, as always, strive to adopt and leverage new, innovative processes and technology to drive its ongoing quality program.

You can and should expect excellent quality from a business that continuously strives to improve its products and services. Van’s approach is to delivering the highest quality products. Our aircraft assembly and delivery department — a dedicated team focused on just that portion of our business — is staffed by experts with years of RV-12 building experience. Van’s will, as always, strive to adopt and leverage new, innovative processes and technology to drive its ongoing quality program. No, not at all. This change is the result of mutual successes, and represents a natural and positive evolution of both businesses. It will enable both companies to deliver even more, both in partnership and separately.

No, not at all. This change is the result of mutual successes, and represents a natural and positive evolution of both businesses. It will enable both companies to deliver even more, both in partnership and separately.

In this article, I am writing about one of most affordable aircraft you can build. Legal Eagle is not available either fully built or in a full kit.

In this article, I am writing about one of most affordable aircraft you can build. Legal Eagle is not available either fully built or in a full kit.

How low can the price go?

How low can the price go? You buy a set of plans for $50 and invest six to nine months of your time. Other packages offer a series of videos and more details. Some builders will choose the welded fuselage and a materials kit though these will increase costs beyond the bare minimum.

You buy a set of plans for $50 and invest six to nine months of your time. Other packages offer a series of videos and more details. Some builders will choose the welded fuselage and a materials kit though these will increase costs beyond the bare minimum.

One essential visit at

One essential visit at  Quad City’s partner, National Ultralight, said “[Our new] EL-65 is a long wing, two seat, high power, high lift aircraft well suited for amphibious floats, heavy loads and high density altitudes. The new ES-65 is a clip wing derivative of the EL-65 optimized for speed with a wing four feet shorter.

Quad City’s partner, National Ultralight, said “[Our new] EL-65 is a long wing, two seat, high power, high lift aircraft well suited for amphibious floats, heavy loads and high density altitudes. The new ES-65 is a clip wing derivative of the EL-65 optimized for speed with a wing four feet shorter. “Affordable” is a variable term that depends on an individual’s budget. What one pilot might afford another cannot. Yet how about this offer from Quad City? “Quick-build packages including airframe, instruments, engine, prop, […everything you need] start at $29,975.” I have to judge that a remarkable bargain in light aviation.

“Affordable” is a variable term that depends on an individual’s budget. What one pilot might afford another cannot. Yet how about this offer from Quad City? “Quick-build packages including airframe, instruments, engine, prop, […everything you need] start at $29,975.” I have to judge that a remarkable bargain in light aviation.

While this space is usually dedicated to cool new airplanes — not boring government policy reviews …yawn! — this article will provide some rays of light to an industry approaching its 15th birthday (in September 2019). I think some of this may surprise you.

While this space is usually dedicated to cool new airplanes — not boring government policy reviews …yawn! — this article will provide some rays of light to an industry approaching its 15th birthday (in September 2019). I think some of this may surprise you. After many meetings with high-level FAA executives and project managers, we are pleased to report that ALL these objectives and one more — increasing the gross weight of LSA — are included in FAA’s present actions regarding rule making. Note that gross weight will probably be determined by a new system other than a fixed-weight number but the exact formula is pending while FAA finalizes their regulation plans.

After many meetings with high-level FAA executives and project managers, we are pleased to report that ALL these objectives and one more — increasing the gross weight of LSA — are included in FAA’s present actions regarding rule making. Note that gross weight will probably be determined by a new system other than a fixed-weight number but the exact formula is pending while FAA finalizes their regulation plans. We are proud of what we’ve been able to accomplish on the skinniest of budgets but we did not fly solo.

We are proud of what we’ve been able to accomplish on the skinniest of budgets but we did not fly solo. So, following a direct request from top FAA executives, we submitted a comprehensive business case for a program that we hope will much sooner allow manufacturers, dealers, owners, operators, and pilots to exercise the core-four-plus-one privileges.

So, following a direct request from top FAA executives, we submitted a comprehensive business case for a program that we hope will much sooner allow manufacturers, dealers, owners, operators, and pilots to exercise the core-four-plus-one privileges.

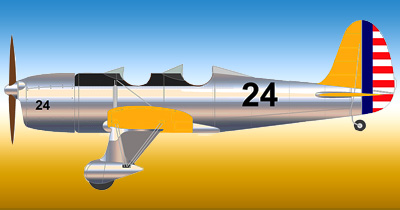

We simply had to do a video interview with the developer of the 1930s-era Ryan ST because of its fascinating history and its handsome good looks. If you love vintage aviation, this should grab your attention as it did mine.

We simply had to do a video interview with the developer of the 1930s-era Ryan ST because of its fascinating history and its handsome good looks. If you love vintage aviation, this should grab your attention as it did mine. The project is not merely a personal fascination for Nick. He will be selling a builder’s kit and specifically chose the 95% scale to make it enough lighter to use modern engines. Nick explains this further in the video. He expects first flight fairly early in 2019.

The project is not merely a personal fascination for Nick. He will be selling a builder’s kit and specifically chose the 95% scale to make it enough lighter to use modern engines. Nick explains this further in the video. He expects first flight fairly early in 2019. Thanks to Nick’s effort, you won’t have to spend nearly that much; he has established a price for his kit: $31,890, not including considerable effort to polish the aluminum as you see in the nearby photos. A quick-build option for $3,000 will likely be popular.

Thanks to Nick’s effort, you won’t have to spend nearly that much; he has established a price for his kit: $31,890, not including considerable effort to polish the aluminum as you see in the nearby photos. A quick-build option for $3,000 will likely be popular. The first Ryan ST flew for the first time on June 8th, 1934 and production began the following year, when nine aircraft were delivered. Production rates remained low — about one aircraft every two weeks — but this changed in 1940 when deliveries to military forces began in earnest to support the war effort. Total production of civil and military aircraft before WWII numbered 315. Another 1,253 military versions were produced in ’42-’43 totaling 1,568 aircraft of all models.

The first Ryan ST flew for the first time on June 8th, 1934 and production began the following year, when nine aircraft were delivered. Production rates remained low — about one aircraft every two weeks — but this changed in 1940 when deliveries to military forces began in earnest to support the war effort. Total production of civil and military aircraft before WWII numbered 315. Another 1,253 military versions were produced in ’42-’43 totaling 1,568 aircraft of all models.

The company now known as SeaMax Aircraft reports manufacturing 152 of its amphibious aircraft. SeaMax M-22, a design by Miguel Rosario, has been delivered to more than 20 countries. In the last year the company established a presence in the U.S. market.

The company now known as SeaMax Aircraft reports manufacturing 152 of its amphibious aircraft. SeaMax M-22, a design by Miguel Rosario, has been delivered to more than 20 countries. In the last year the company established a presence in the U.S. market.

Seamax won aeronautical awards, such as the prestigious “Outstanding Commercial SLSA” at Sun ‘n Fun in the United States and the Schneider Cup in Italy. It has been featured in more than 40 specialized magazines around the world.

Seamax won aeronautical awards, such as the prestigious “Outstanding Commercial SLSA” at Sun ‘n Fun in the United States and the Schneider Cup in Italy. It has been featured in more than 40 specialized magazines around the world.

That’s quite admirable for a fresh-out-of-the-gate design entering a marketplace with more than 140 Special Light-Sport Aircraft appearing on

That’s quite admirable for a fresh-out-of-the-gate design entering a marketplace with more than 140 Special Light-Sport Aircraft appearing on  “Our team has been extremely busy since we’ve been back from Oshkosh,” added Amy. “Traveling to the show in four of our Ranger R7s was an awesome experience and we had an easy arrival into Wittman Airport Saturday morning.” Arriving two days before the show began proved wise when heavy arrival traffic delayed many inbound aircraft as the show was starting.

“Our team has been extremely busy since we’ve been back from Oshkosh,” added Amy. “Traveling to the show in four of our Ranger R7s was an awesome experience and we had an easy arrival into Wittman Airport Saturday morning.” Arriving two days before the show began proved wise when heavy arrival traffic delayed many inbound aircraft as the show was starting. Even more recently, another Vashon LSA was delivered. “We delivered our second Ranger to a local flight school right at our home airport at Paine Field,” boasted Amy!

Even more recently, another Vashon LSA was delivered. “We delivered our second Ranger to a local flight school right at our home airport at Paine Field,” boasted Amy!

For your enjoyment, here is arguably the most unique airplane I found on the grounds of EAA AirVenture Oshkosh 2018 …and with around 3,000 show planes, that is truly saying something.

For your enjoyment, here is arguably the most unique airplane I found on the grounds of EAA AirVenture Oshkosh 2018 …and with around 3,000 show planes, that is truly saying something. What you are seeing in the nearby photos and videos below is Peter Sripol‘s man-carrying scratch-built aircraft project.

What you are seeing in the nearby photos and videos below is Peter Sripol‘s man-carrying scratch-built aircraft project. The fuel source is a series of nine batteries driving dual model-airplane engines. Peter built a first ultralight that EAA reported “was minimally planned, in contrast to [this] design, which [he] took time to design in CAD.” The first video explains why the motors have the wood constructions holding them along with other design considerations. The second video, Peter’s, shows some of the other building effort.

The fuel source is a series of nine batteries driving dual model-airplane engines. Peter built a first ultralight that EAA reported “was minimally planned, in contrast to [this] design, which [he] took time to design in CAD.” The first video explains why the motors have the wood constructions holding them along with other design considerations. The second video, Peter’s, shows some of the other building effort.

“As promised,

“As promised,  Events like the one AeroJones hosted may be critically important to introduce literally billions of people in the Asian-Pacific region to the idea of flying for fun.

Events like the one AeroJones hosted may be critically important to introduce literally billions of people in the Asian-Pacific region to the idea of flying for fun. In addition to China and Taiwan, AeroJones Aviation is able to ship fully manufactured CTLS aircraft to other Asia-Pacific countries including Australia, New Zealand, Indonesia, Malaysia, Philippines, Japan, Korea, and Thailand.

In addition to China and Taiwan, AeroJones Aviation is able to ship fully manufactured CTLS aircraft to other Asia-Pacific countries including Australia, New Zealand, Indonesia, Malaysia, Philippines, Japan, Korea, and Thailand. You have more privileges than you may know with your Light-Sport Aircraft.

You have more privileges than you may know with your Light-Sport Aircraft.

“I deliver on wheels but for $300, an owner can add the float option, which provides mounting brackets attached to specially-reinforced fuselage points.”

“I deliver on wheels but for $300, an owner can add the float option, which provides mounting brackets attached to specially-reinforced fuselage points.”

Maybe you never flew a floatplane or seaplane (the latter implying a hull). If that’s true you are missing one of the singular pleasures of flying. Landing on water is almost unreal. It seems unlikely but when you find yourself about to touchdown on a lake, you know you have arrived in a way few people in history have ever considered much less achieved.

Maybe you never flew a floatplane or seaplane (the latter implying a hull). If that’s true you are missing one of the singular pleasures of flying. Landing on water is almost unreal. It seems unlikely but when you find yourself about to touchdown on a lake, you know you have arrived in a way few people in history have ever considered much less achieved. If you must have two seats, FireFly loses out, being designed expressly to be a single seater. Nonetheless, if budget is a primary driver for your airplane purchase, as it is for most people, the FireFly on floats looks to be a highly attractive option.

If you must have two seats, FireFly loses out, being designed expressly to be a single seater. Nonetheless, if budget is a primary driver for your airplane purchase, as it is for most people, the FireFly on floats looks to be a highly attractive option.

A new-to-Americans Light-Sport Aircraft made its debut showing at AirVenture 2018. Here is the Magnus Aircraft Fusion 212.

A new-to-Americans Light-Sport Aircraft made its debut showing at AirVenture 2018. Here is the Magnus Aircraft Fusion 212. Snyder and Foldesi exhibited their brightly painted low wing that uses mostly carbon fiber construction and a dual taper wing. Full dual controls are available at both seats. Toe brakes on each side guide a castoring nose wheel via differential braking. Rudder pedals are adjustable to accommodate pilot height differences. Leather upholstery is used throughout and cabin heat is provided.

Snyder and Foldesi exhibited their brightly painted low wing that uses mostly carbon fiber construction and a dual taper wing. Full dual controls are available at both seats. Toe brakes on each side guide a castoring nose wheel via differential braking. Rudder pedals are adjustable to accommodate pilot height differences. Leather upholstery is used throughout and cabin heat is provided. “This low-wing monoplane [has a] symmetrical wing profile that provides it with superb aerobatic capabilities,” said Magnus Aircraft. However, the company advised, “While the aircraft has aerobatic capabilities … as a Normal Category SLSA aircraft, Fusion 212 is presently limited to a maximum of 60 degrees of bank and a maximum pitch up or down of 30 degrees when operating in the United States.”

“This low-wing monoplane [has a] symmetrical wing profile that provides it with superb aerobatic capabilities,” said Magnus Aircraft. However, the company advised, “While the aircraft has aerobatic capabilities … as a Normal Category SLSA aircraft, Fusion 212 is presently limited to a maximum of 60 degrees of bank and a maximum pitch up or down of 30 degrees when operating in the United States.”

The Santoms will take over production and sales of the single place Hawk models including the Part 103 model and the Ultra, a somewhat beefier model that is built as an Experimental Amateur Built (EAB). My discussion with Bob and LB was encouraging. I was impressed to hear the enthusiasm from father and son for keeping this series of Hawks available.

The Santoms will take over production and sales of the single place Hawk models including the Part 103 model and the Ultra, a somewhat beefier model that is built as an Experimental Amateur Built (EAB). My discussion with Bob and LB was encouraging. I was impressed to hear the enthusiasm from father and son for keeping this series of Hawks available. On my first day on Wittman Field here in Oshkosh, Wisconsin, we took the privilege to drive around the grounds and capture video scenes as hundreds of exhibitors arrive and set up their displays.

On my first day on Wittman Field here in Oshkosh, Wisconsin, we took the privilege to drive around the grounds and capture video scenes as hundreds of exhibitors arrive and set up their displays. We will have lots more to report and will capture many videos for you, but here’s a little five-minute glimpse of what it looks like as the show unfolds before our eyes.

We will have lots more to report and will capture many videos for you, but here’s a little five-minute glimpse of what it looks like as the show unfolds before our eyes.