Outgoing CEO of Remos AG, Hanns-Friedrich Begemann, welcomed the merger "as a logical consequence of the successful existing cooperation and development of the respective markets."

Outgoing CEO of Remos AG, Hanns-Friedrich Begemann, welcomed the merger "as a logical consequence of the successful existing cooperation and development of the respective markets."

News & Video on Light-Sport Aircraft, Sport Pilot Kits, and Ultralight Aircraft

By Dan Johnson || 2 Comments (Edit)

Outgoing CEO of Remos AG, Hanns-Friedrich Begemann, welcomed the merger "as a logical consequence of the successful existing cooperation and development of the respective markets."

Outgoing CEO of Remos AG, Hanns-Friedrich Begemann, welcomed the merger "as a logical consequence of the successful existing cooperation and development of the respective markets."

On April 13, 2017, only briefly after the Aero Friedrichshafen show ended, LSA manufacturer Remos has a major announcement. “Remos has a New Owner,” exclaimed the German company on their website home page. Stemme and Remos decided to work together more closely. “The only logical step was to merge both companies. Stemme AG ist the new owner of Remos AG. Remos now is a 100% subsidiary of Stemme,” said Stemme CEO Paul Masschelein. Stemme’s facility in Strausberg and the Remos facility in Pasewalk will continue to operate. To reassure customers old and new, Masschelein added, “The Remos GX is a major part of our plans for the future.” Both companies are referring to the move as a “merger.” This transaction follows a cooperation beginning in 2014 when Remos AG began producing structural composite parts for Stemme. “The agreement has been unanimously approved by both companies’ supervisory boards,” they reported.

By Dan Johnson || 12 Comments (Edit)

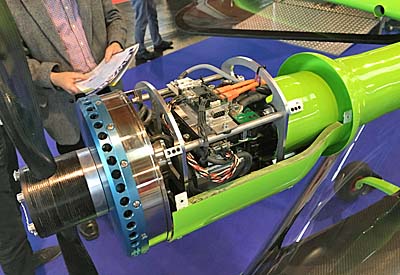

Swan (green) is seen with a clean electric motor installation at Aero 2017. The white one from an earlier Aero has a gasoline engine. Puppies are optional.

SWAN is a single-seater ultralight aircraft created and manufactured by Modern Wings. Swan is made of light composite materials that allow it a refined and smooth shape compared to older ultralight entries. The company, lead by Radu Berceanu, was formed in 2007 "with the goal of producing high quality ultralight aircraft at low costs."

SWAN is a single-seater ultralight aircraft created and manufactured by Modern Wings. Swan is made of light composite materials that allow it a refined and smooth shape compared to older ultralight entries. The company, lead by Radu Berceanu, was formed in 2007 "with the goal of producing high quality ultralight aircraft at low costs."

Radu and Modern Wings offer several varieties of Swan. One is a version with 115 kilogram (253 pound) empty weight which meets the requirements of the USA Part 103 regulation and those of Great Britain's sub-microlight SSDR regulation.

Another version with 120 kg empty weight meets the requirements of Germany's regulation.

"We ruled out all configurations that can be problematical for an inexperienced pilot," said Radu, to include a pusher engine and a tailwheel landing gear model.

Swan 120 — when a gasoline-powered aircraft — is a high-wing ultralight that weighs 240 pounds empty when equipped with a Polini 250 engine (the sort often used on larger powered paraglider). The Romanian company displayed a standard Polini-equipped aircraft at Aero 2017, but also had a Geiger-equipped alternative. This was still as a prototype, Roy clarified.

"The installation of the electric motor was very clean, with the boom-mounted powerplant located right where the typical gasser engine would be," observed Roy. "The battery installation on this one is better than on some designs, which pack the batteries into the existing engine compartment." Instead, batteries for Swan were mounted under the passenger seat, which no doubt improves the center of gravity and stability of the aircraft. It would also seem safer in the event of a poor landing or other mishap.

"Swan was just one example of electric power being offered, or soon to be offered right next to gasoline-powered aircraft at Aero 2017," concluded Roy. Learn more about Swan at Modern Wings. To have direct contact, email Andrei Berceanu.

The Romanian company displayed a standard Polini-equipped aircraft at Aero 2017, but also had a Geiger-equipped alternative. This was still as a prototype, Roy clarified.

"The installation of the electric motor was very clean, with the boom-mounted powerplant located right where the typical gasser engine would be," observed Roy. "The battery installation on this one is better than on some designs, which pack the batteries into the existing engine compartment." Instead, batteries for Swan were mounted under the passenger seat, which no doubt improves the center of gravity and stability of the aircraft. It would also seem safer in the event of a poor landing or other mishap.

"Swan was just one example of electric power being offered, or soon to be offered right next to gasoline-powered aircraft at Aero 2017," concluded Roy. Learn more about Swan at Modern Wings. To have direct contact, email Andrei Berceanu.

In my views of Swan at previous Aero Friedrichshafen shows, the design caught my eye as it was (a) a single seater, (b) light enough to qualify as a Part 103 ultralight or its European equivalents, and (c) as it was an all-composite, nicely designed aircraft. Commonly, Part 103-capable designs are much more basic to remain within the tight limits. This statement also applies to the German 120-kilogram category or to Britain’s Single Seat DeRegulated (SSDR) description. As Aero contributor and Powered Sport Flying publisher Roy Beisswenger and I frequently discuss, the most likely place for electric propulsion to work today is in ultralights. This is because in very light aircraft with more local flying missions, battery weights for a modest period of flying (30-60 minutes) is already achievable in the very lightest of powered aircraft. We have been discussing this with FAA for more than three years.

By Dan Johnson || 9 Comments (Edit)

John Hunter has extensive experience with Drifter, AirCam, and several Aeroprakt models. Recently, he has been in Italy visiting Innovaviation to conduct the first test flights.

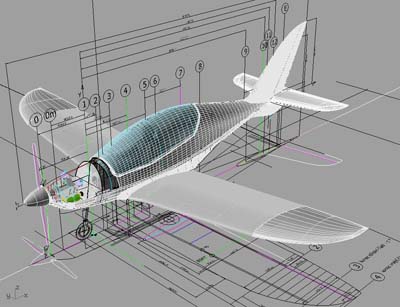

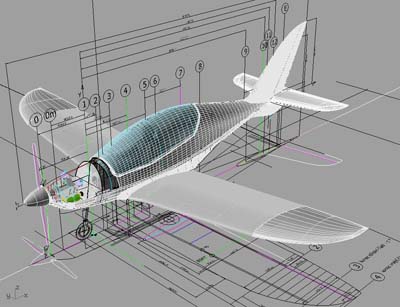

Created by JetFox designer, Alfredo Di Cesare, FX 1 is a modern aircraft cabin and fuselage structure made primarily of light weight carbon-graphite composite with wings and tail built from aluminum. Under the shapely skin is a cage of welded chromoly steel that provides robust occupant protection.

Alfredo wrote, "FX1 is a fourth-generation sport plane [that] evolved from successful European designs of the last three decades." Using computer-aided design FX1 "has been carefully engineered to optimize all aspects of a proven configuration."

Additional details including many more photos plus design considerations can be found on Innovaviation's website.

John Hunter has extensive experience with Drifter, AirCam, and several Aeroprakt models. Recently, he has been in Italy visiting Innovaviation to conduct the first test flights.

Created by JetFox designer, Alfredo Di Cesare, FX 1 is a modern aircraft cabin and fuselage structure made primarily of light weight carbon-graphite composite with wings and tail built from aluminum. Under the shapely skin is a cage of welded chromoly steel that provides robust occupant protection.

Alfredo wrote, "FX1 is a fourth-generation sport plane [that] evolved from successful European designs of the last three decades." Using computer-aided design FX1 "has been carefully engineered to optimize all aspects of a proven configuration."

Additional details including many more photos plus design considerations can be found on Innovaviation's website.

"The aircraft is stable, yet responsive. It does not display control sensitivity in any axis, yet control response is very positive. It can easily be flown with neutral trim throughout it's speed range, including all three stages of flap deployment (15º, 30º, and 45º).

"In flight it does not exhibit significant changes pitch with the application or retraction of power, and controls do not become heavy from changes in configuration or speed. Stall behavior is "tame" and predictable, exhibiting a mild break, shallow pitching and a quick recovery.

"Seating is comfortable, and adjustable fore and aft. The optional side-stick control system works well, and I found the aircraft easy to fly from either seat (left seat requires left-hand control, with right-hand for the right seat). The standard control will be conventional dual joy-sticks, centrally mounted. A vernier throttle is installed at the center of the panel. Control for the hydraulic brakes is a manual lever mounted forward between the seats, and includes a parking brake valve. Turn radius is adequate for ramp maneuvers.

"The aircraft is stable, yet responsive. It does not display control sensitivity in any axis, yet control response is very positive. It can easily be flown with neutral trim throughout it's speed range, including all three stages of flap deployment (15º, 30º, and 45º).

"In flight it does not exhibit significant changes pitch with the application or retraction of power, and controls do not become heavy from changes in configuration or speed. Stall behavior is "tame" and predictable, exhibiting a mild break, shallow pitching and a quick recovery.

"Seating is comfortable, and adjustable fore and aft. The optional side-stick control system works well, and I found the aircraft easy to fly from either seat (left seat requires left-hand control, with right-hand for the right seat). The standard control will be conventional dual joy-sticks, centrally mounted. A vernier throttle is installed at the center of the panel. Control for the hydraulic brakes is a manual lever mounted forward between the seats, and includes a parking brake valve. Turn radius is adequate for ramp maneuvers.

"The first flap position (15º) is recommended for takeoff. On turf, the nose gear can be rotated in 5 seconds, and liftoff occurs 8 seconds from standstill, with winds calm and a takeoff weight of 950 pounds (solo flight with 50% fuel). Takeoff roll is approximately 320 feet. Standard day rate of climb at 80 mph is 1,050 feet per minute.

"On landing, the first flap position is recommended on downwind, second on crosswind (30º), and third on final (45º, full flaps). The fowler flaps are effective, and necessary for short field operations. The aircraft exhibits low drag, and speed control is imperative for short runways. The aircraft flares well, and is easy to land. When I asked for speeds, John noted he used 75 mph on downwind, 60 on base leg, and 55 over the fence after full flaps (45º) were deployed.

"The cabin is comfortable, relatively quiet, and visibility is excellent. The FX1 has a high-quality feel, and is a pleasure to fly."

"The first flap position (15º) is recommended for takeoff. On turf, the nose gear can be rotated in 5 seconds, and liftoff occurs 8 seconds from standstill, with winds calm and a takeoff weight of 950 pounds (solo flight with 50% fuel). Takeoff roll is approximately 320 feet. Standard day rate of climb at 80 mph is 1,050 feet per minute.

"On landing, the first flap position is recommended on downwind, second on crosswind (30º), and third on final (45º, full flaps). The fowler flaps are effective, and necessary for short field operations. The aircraft exhibits low drag, and speed control is imperative for short runways. The aircraft flares well, and is easy to land. When I asked for speeds, John noted he used 75 mph on downwind, 60 on base leg, and 55 over the fence after full flaps (45º) were deployed.

"The cabin is comfortable, relatively quiet, and visibility is excellent. The FX1 has a high-quality feel, and is a pleasure to fly."

FX1 Performance Specifications

FX1 Dimensions & Details

FX 1 was designed to conform to American regulations. John's goal has been to establish production of the FX1 in the United States, both for the domestic market and for export. "I have been working with Innovaviation over the past two years towards that end, and having just flown the plane, we are definitely on the right track," John expressed.

When Fx1 makes landfall in the USA, we will look toward a video interview with John and perhaps a fuller flight report. If interested to keep up with John Hunter's effort to import FX1, call (207) 271-3040.

FX 1 was designed to conform to American regulations. John's goal has been to establish production of the FX1 in the United States, both for the domestic market and for export. "I have been working with Innovaviation over the past two years towards that end, and having just flown the plane, we are definitely on the right track," John expressed.

When Fx1 makes landfall in the USA, we will look toward a video interview with John and perhaps a fuller flight report. If interested to keep up with John Hunter's effort to import FX1, call (207) 271-3040.

In the late 1990s, the Italian JetFox 97 flew as an evolved ultralight. Resembling the FlightStar that sold around 1,000 units in all configurations, JetFox differed by enclosing the engine and cabin. Instead of a simple tail boom the European ultralight had an aft fuselage among other refinements. As Light-Sport erupted into the marketplace, JetFox appeared to slip away. However, good ideas can be recycled and revived. Such appears to be the case for FX1. John Hunter has extensive experience with Drifter, AirCam, and several Aeroprakt models. Recently, he has been in Italy visiting Innovaviation to conduct the first test flights. Created by JetFox designer, Alfredo Di Cesare, FX 1 is a modern aircraft cabin and fuselage structure made primarily of light weight carbon-graphite composite with wings and tail built from aluminum. Under the shapely skin is a cage of welded chromoly steel that provides robust occupant protection. Alfredo wrote, “FX1 is a fourth-generation sport plane [that] evolved from successful European designs of the last three decades.” Using computer-aided design FX1 “has been carefully engineered to optimize all aspects of a proven configuration.” Additional details including many more photos plus design considerations can be found on Innovaviation’s website.

By Dan Johnson || Leave a Comment (Edit)

Prominently displayed in front of the Rotax Aircraft Engines exhibit at Sun 'n Fun — right at the main entrance to the large spring show — was a strikingly-painted Searey kit-built aircraft (photo). Why? The mission was to showcase how a Rotax-powered amphibian aircraft can get more push… without complexity.

Named Searey ATD, Advanced Technology Demonstrator, the collaborators include Progressive Aerodyne, producer of the Searey, Rotax Aircraft Engines, and MT Propeller, all coordinated by key developer, RS Aerotech of Nassau, Bahamas.

A joint news release said, "For the first time in the Light-Sport Aircraft category*, Searey ATD offers a single-lever operated constant speed propeller, which significantly improves performance and dramatically reduces power management complexity for the pilot."

Searey ATD "will be used for long-time testing of new engines, propellers, and electronic systems." To serve this goal, Searey ATD has been equipped with a state-of-the-art flight data acquisition and reporting system, which combines engine data with aircraft and navigation data." Called a "first time" accomplishment, Searey ATD can "automatically transmit its engine and aircraft data via LTE networks worldwide." The data "will be used by Rotax to perform engine health monitoring" similar to what airlines do globally.

Prominently displayed in front of the Rotax Aircraft Engines exhibit at Sun 'n Fun — right at the main entrance to the large spring show — was a strikingly-painted Searey kit-built aircraft (photo). Why? The mission was to showcase how a Rotax-powered amphibian aircraft can get more push… without complexity.

Named Searey ATD, Advanced Technology Demonstrator, the collaborators include Progressive Aerodyne, producer of the Searey, Rotax Aircraft Engines, and MT Propeller, all coordinated by key developer, RS Aerotech of Nassau, Bahamas.

A joint news release said, "For the first time in the Light-Sport Aircraft category*, Searey ATD offers a single-lever operated constant speed propeller, which significantly improves performance and dramatically reduces power management complexity for the pilot."

Searey ATD "will be used for long-time testing of new engines, propellers, and electronic systems." To serve this goal, Searey ATD has been equipped with a state-of-the-art flight data acquisition and reporting system, which combines engine data with aircraft and navigation data." Called a "first time" accomplishment, Searey ATD can "automatically transmit its engine and aircraft data via LTE networks worldwide." The data "will be used by Rotax to perform engine health monitoring" similar to what airlines do globally.

Progressive Aerodyne owner Adam Yank poses beside his Searey Elite at Sun 'n Fun. His company could benefit from the work achieved by RS Aerotech.

Searey Elite features a modern glass instrument panel. The SLSA model might one day offer an adjustable pitch prop; experimental models could offer it even sooner, if builder/customers wish.

Close up of the RS Aerotech project using a single-lever control coupled to a MT Prop. Photo courtesy of Rotax News

Could Light-Sport Aircraft, light kit aircraft, and even ultralights benefit from in-flight adjustable propellers? After more testing and data collection answering that question should be easier. Prominently displayed in front of the Rotax Aircraft Engines exhibit at Sun ‘n Fun — right at the main entrance to the large spring show — was a strikingly-painted Searey kit-built aircraft (photo). Why? The mission was to showcase how a Rotax-powered amphibian aircraft can get more push… without complexity. Named Searey ATD, Advanced Technology Demonstrator, the collaborators include Progressive Aerodyne, producer of the Searey, Rotax Aircraft Engines, and MT Propeller, all coordinated by key developer, RS Aerotech of Nassau, Bahamas. A joint news release said, “For the first time in the Light-Sport Aircraft category*, Searey ATD offers a single-lever operated constant speed propeller, which significantly improves performance and dramatically reduces power management complexity for the pilot.” Searey ATD “will be used for long-time testing of new engines, propellers, and electronic systems.” To serve this goal, Searey ATD has been equipped with a state-of-the-art flight data acquisition and reporting system, which combines engine data with aircraft and navigation data.” Called a “first time” accomplishment, Searey ATD can “automatically transmit its engine and aircraft data via LTE networks worldwide.” The data “will be used by Rotax to perform engine health monitoring” similar to what airlines do globally.

By Dan Johnson || Leave a Comment (Edit)

On Wednesday, April 5, the Global Show for General Aviation started for the 25th time. The 2017 edition opened with a record participation of 707 exhibitors from 39 countries, some 100 more than in 2016, presenting the best results in its history. Not only did more vendors attend this benchmark Aero, even the number of visitors numbers increased on first three days by six percent.

With Sun 'n Fun also reporting record numbers, the health of lighter aviation appears strong and vibrant.

On a closing day Aero project manager Roland Bosch was the happiest man on earth. He told me that Aero 2017 set a double record: 34,200 trade visitors (2016: 30,800 —2015: 33,900) and the highest number of exhibitors adding: "Good flight weather, a great anniversary party, satisfied exhibitors, and above all, a visitor and exhibitor record."

On Wednesday, April 5, the Global Show for General Aviation started for the 25th time. The 2017 edition opened with a record participation of 707 exhibitors from 39 countries, some 100 more than in 2016, presenting the best results in its history. Not only did more vendors attend this benchmark Aero, even the number of visitors numbers increased on first three days by six percent.

With Sun 'n Fun also reporting record numbers, the health of lighter aviation appears strong and vibrant.

On a closing day Aero project manager Roland Bosch was the happiest man on earth. He told me that Aero 2017 set a double record: 34,200 trade visitors (2016: 30,800 —2015: 33,900) and the highest number of exhibitors adding: "Good flight weather, a great anniversary party, satisfied exhibitors, and above all, a visitor and exhibitor record."

The fair-chief, CEO Klaus Wellmann said: "It is now clear that our Aero is the most important business meeting for the aviation industry in Europe boasting many premieres." As is often the case with this event, many novel aircraft were presented.

The largest general aviation exhibition in Europe offers everything that flies from gliders to business jets, but the seven massive exhibition halls (each the size of a basketball gymnasium) regularly offer a huge presence of European ultralight or microlight aircraft. These are comparable to American Light-Sport Aircraft. Fixed wings, gyroplanes, weight shift, electric power, gasoline power, diesel power, and so much more fill the halls to capacity.

On day prior the start, on Tuesday, and on a closing day, on Saturday several aircraft with electric propulsion systems flew their rounds silently in the sky over the fairgrounds (photos).

In the days ahead, we will offer lots more information about Aero and Sun 'n Fun 2017, two events that both set records and had the interesting aircraft to prove it.

The fair-chief, CEO Klaus Wellmann said: "It is now clear that our Aero is the most important business meeting for the aviation industry in Europe boasting many premieres." As is often the case with this event, many novel aircraft were presented.

The largest general aviation exhibition in Europe offers everything that flies from gliders to business jets, but the seven massive exhibition halls (each the size of a basketball gymnasium) regularly offer a huge presence of European ultralight or microlight aircraft. These are comparable to American Light-Sport Aircraft. Fixed wings, gyroplanes, weight shift, electric power, gasoline power, diesel power, and so much more fill the halls to capacity.

On day prior the start, on Tuesday, and on a closing day, on Saturday several aircraft with electric propulsion systems flew their rounds silently in the sky over the fairgrounds (photos).

In the days ahead, we will offer lots more information about Aero and Sun 'n Fun 2017, two events that both set records and had the interesting aircraft to prove it.

The German aviation trade fair or show is Aero Friedrichshafen. This year the event at the very southern edge of Germany celebrated its 25th birthday. Over the years, Aero has emerged as the premiere aviation event in Europe, at least for airplanes that ordinary people can afford. Good friend and highly accomplished journalist, Marino Boric, submitted a lengthy report on the event, which we will break up into more bite-sized pieces. Here is Marino’s overview. —DJ On Wednesday, April 5, the Global Show for General Aviation started for the 25th time. The 2017 edition opened with a record participation of 707 exhibitors from 39 countries, some 100 more than in 2016, presenting the best results in its history. Not only did more vendors attend this benchmark Aero, even the number of visitors numbers increased on first three days by six percent. With Sun ‘n Fun also reporting record numbers, the health of lighter aviation appears strong and vibrant.

By Dan Johnson || Leave a Comment (Edit)

Blue Angels seen on the Lakeland ramp at the occasion of the AutoGyro party. The jet team's flawless performance accented the light side of Sun 'n Fun.

A few years ago, Paradise City volunteer and former airline captain George Karamitis was awarded a 50 year safe flying award from FAA. He flies his Quicksilver nearly every day, often posting to Facebook.

Randee Laskewitz and Ray Bradford are the heart and soul of the LAMA LSA Mall and Engine Display. Without these two, those central parts of Paradise could not function. As the LSA Mall celebrated its 10th year, Randee and Ray were awarded their 10-year volunteers pins in 2017.

John “Lites” Leenhouts announced to a largest-ever gathering of volunteers that the event had set all-time records for attendance at the 2017. Clearly pumped by the positive results, Lites made his way around the small army expressing himself like the gracious professional he is. How good was attendance? “They completely ran out of weekly armbands and had to resort to some 2016 armbands or daily ones,” said longtime reporter and co-star of Uncontrolled Airspace Dave Higdon, who has regularly attended Sun ‘n Fun since the early 1980s. We discussed the event and its evolution to become a major worldwide aviation show as Dave and I also celebrated 40 years since my hang gliding school taught him how to fly (we were mighty young in those days, I rush to add). Ben Sclair, publisher of the airshow newspaper, “Sun ‘n Fun Today,” and General Aviation News backed up the assertion of very strong results for 2017 Sun ‘n Fun, saying that not only did his paper have a full slate of advertisers but he’d personally seen solid traffic everywhere he went tracking down stories for the daily to report.

By Dan Johnson || Leave a Comment (Edit)

Welcome to the new US Flight Expo. Less like Sun 'n Fun and AirVenture with their airshow components and vast acreage of airplanes of all types, US Flight Expo will perhaps more closely resemble Sebring, Midwest LSA Expo, or DeLand …all arguably part of an emerging trend toward sector-focused shows that offer more manageable crowds giving easier contact with aircraft vendors and superb access to aircraft demo flights.

Coming up very soon, US Flight Expo runs May 3-4-5-6, 2017 at the Marana Regional Airport (KAVQ) near Tucson, Arizona and about an hour south of Phoenix.

Welcome to the new US Flight Expo. Less like Sun 'n Fun and AirVenture with their airshow components and vast acreage of airplanes of all types, US Flight Expo will perhaps more closely resemble Sebring, Midwest LSA Expo, or DeLand …all arguably part of an emerging trend toward sector-focused shows that offer more manageable crowds giving easier contact with aircraft vendors and superb access to aircraft demo flights.

Coming up very soon, US Flight Expo runs May 3-4-5-6, 2017 at the Marana Regional Airport (KAVQ) near Tucson, Arizona and about an hour south of Phoenix.

Organized by Arion Lightning dealer and light aviation enthusiast Greg Hobbs, the sector we usually cover here on ByDanJohnson.com looks to be well represented. Consider the list below. The other shows are all in the eastern U.S., a phenomenon I've discussed with many people over the years. For whatever reason, no major show has come to dominate the expansive western U.S.

Copperstate and Arlington are two of the best established and they are fine shows yet neither draws the immense crowds of the two big eastern events. Are sector-focused shows truly a new thing? We'll see but meanwhile, a well-produced event near the southern desert city could be most welcome. Traveling east to shows can be a nice change of pace but western U.S. recreational pilots may embrace something closer to home.

Organized by Arion Lightning dealer and light aviation enthusiast Greg Hobbs, the sector we usually cover here on ByDanJohnson.com looks to be well represented. Consider the list below. The other shows are all in the eastern U.S., a phenomenon I've discussed with many people over the years. For whatever reason, no major show has come to dominate the expansive western U.S.

Copperstate and Arlington are two of the best established and they are fine shows yet neither draws the immense crowds of the two big eastern events. Are sector-focused shows truly a new thing? We'll see but meanwhile, a well-produced event near the southern desert city could be most welcome. Traveling east to shows can be a nice change of pace but western U.S. recreational pilots may embrace something closer to home.

Vast Western landscapes can be incredibly beautiful as the photos show. Greg is a hardworking fellow who has been laboring to build this event for the benefit of airplane enthusiasts and the vendors who serve them. He said early May is pleasantly warm and temperate with deep blue skies.

A video interview with Greg at Sun 'n Fun will be ready shortly but if you want to find out more soon, here's some contacts:

Vast Western landscapes can be incredibly beautiful as the photos show. Greg is a hardworking fellow who has been laboring to build this event for the benefit of airplane enthusiasts and the vendors who serve them. He said early May is pleasantly warm and temperate with deep blue skies.

A video interview with Greg at Sun 'n Fun will be ready shortly but if you want to find out more soon, here's some contacts:

Sun ‘n Fun is not even over; a final day remains (Sunday, April 9th). Yet already, airplane sellers are looking at another show, this one out West. Welcome to the new US Flight Expo. Less like Sun ‘n Fun and AirVenture with their airshow components and vast acreage of airplanes of all types, US Flight Expo will perhaps more closely resemble Sebring, Midwest LSA Expo, or DeLand …all arguably part of an emerging trend toward sector-focused shows that offer more manageable crowds giving easier contact with aircraft vendors and superb access to aircraft demo flights. Coming up very soon, US Flight Expo runs May 3-4-5-6, 2017 at the Marana Regional Airport (KAVQ) near Tucson, Arizona and about an hour south of Phoenix. Organized by Arion Lightning dealer and light aviation enthusiast Greg Hobbs, the sector we usually cover here on ByDanJohnson.com looks to be well represented.

By Dan Johnson || 5 Comments (Edit)

Videoman Dave first pulled me aside to look at an unusual ultralight aircraft nestled in the homebuilt area hidden behind a row of porta-potties. It was a questionable (but, surprisingly not stinky) location for what I had to admit was one truly fascinating aircraft. Check out Lightning Bug!

Sun 'n Fun Paradise City volunteers and officials evidently agreed that Lightning Bug was too fun and too novel to be sequestered behind the biffies. Out it came to a prominent position right in front of the area headquarters tent. In this central spot, this sweet little flying creation steadily drew a crowd.

I missed seeing Lightning Bug take to the air on Friday, April 7th, but I was told it looked good. This despite fairly strong winds that crossed the runway at angles approaching 90 degrees. Other light aircraft managed to fly normally so why does this surprise me?

Videoman Dave first pulled me aside to look at an unusual ultralight aircraft nestled in the homebuilt area hidden behind a row of porta-potties. It was a questionable (but, surprisingly not stinky) location for what I had to admit was one truly fascinating aircraft. Check out Lightning Bug!

Sun 'n Fun Paradise City volunteers and officials evidently agreed that Lightning Bug was too fun and too novel to be sequestered behind the biffies. Out it came to a prominent position right in front of the area headquarters tent. In this central spot, this sweet little flying creation steadily drew a crowd.

I missed seeing Lightning Bug take to the air on Friday, April 7th, but I was told it looked good. This despite fairly strong winds that crossed the runway at angles approaching 90 degrees. Other light aircraft managed to fly normally so why does this surprise me?

One look at the photos ought to explain but what you can't see is that Lightning Bug weighs a mere 140 pounds and employs unorthodox control surfaces. I don't think I've ever seen a three axis flying machine, 'er… ultralight vehicle that comes in an amazing 114 pounds under the tight weight limit of Part 103.

The work of Brian Austein, Lighting Bug is not planned as a product. Brian grew up flying model aircraft, radio control airplanes. He wanted to see if he could make a low-cost aircraft that could be powered by twin engines that are tiny compared to most ultralights but very large for a radio-controls model. Some years ago RC models with spans of a few inches to a 3-4 feet went fully electric. Larger ones, up to 50% scale said Brian, use the engines he mounted on Lightning Bug.

His investment, not counting the value of his time: about $3,000, $1,000 for each engine and $1,000 for his novel airframe that uses elevons and other moveable surfaces you simply don't see on, well… "normal" aircraft. I was completely impressed not only by the extreme creativity in assembling an aircraft with looks unique to any I've ever seen, but to Brian's thoughtful consideration and by the quality of the workmanship.

One look at the photos ought to explain but what you can't see is that Lightning Bug weighs a mere 140 pounds and employs unorthodox control surfaces. I don't think I've ever seen a three axis flying machine, 'er… ultralight vehicle that comes in an amazing 114 pounds under the tight weight limit of Part 103.

The work of Brian Austein, Lighting Bug is not planned as a product. Brian grew up flying model aircraft, radio control airplanes. He wanted to see if he could make a low-cost aircraft that could be powered by twin engines that are tiny compared to most ultralights but very large for a radio-controls model. Some years ago RC models with spans of a few inches to a 3-4 feet went fully electric. Larger ones, up to 50% scale said Brian, use the engines he mounted on Lightning Bug.

His investment, not counting the value of his time: about $3,000, $1,000 for each engine and $1,000 for his novel airframe that uses elevons and other moveable surfaces you simply don't see on, well… "normal" aircraft. I was completely impressed not only by the extreme creativity in assembling an aircraft with looks unique to any I've ever seen, but to Brian's thoughtful consideration and by the quality of the workmanship.

A variety of materials were used to build this head-turning aircraft. Welded steel provides the basic structure with foam core and aluminum spar wings. Control surfaces are covered with see-through monokote as you'd find on many model aircraft, again hewing to Brian's background.

Lightning Bug has a tiny 19.5-foot span comprised of two eight foot wings and a 3.5-foot center section. The canard up front allows Brian to rotate off the ground more controllably but when he says it "Will Not Stall," he does not refer to the canard preventing a break.

On top of everything else about this awesome, singular product, it is equipped with "auto pilot." Is your head starting to spin? Mine sure was.

A couple years ago, Brian developed the Woodpecker and proceeded to win several awards at Oshkosh, he reported. That machine was not sold either showing this is a fascination for achieving super-affordable and novel aircraft that meld full-scale, man-carrying aircraft to techniques employed in assembling RC aircraft. From the constant attention Lightning Bug generated, it is obvious I was not the only one wowed by this young man's design prowess and his unconventional approach. Bravo, Brian!

Fortunately, Brian consented to a video interview so you will get a fuller story after Videoman Dave gets the editing done.

A variety of materials were used to build this head-turning aircraft. Welded steel provides the basic structure with foam core and aluminum spar wings. Control surfaces are covered with see-through monokote as you'd find on many model aircraft, again hewing to Brian's background.

Lightning Bug has a tiny 19.5-foot span comprised of two eight foot wings and a 3.5-foot center section. The canard up front allows Brian to rotate off the ground more controllably but when he says it "Will Not Stall," he does not refer to the canard preventing a break.

On top of everything else about this awesome, singular product, it is equipped with "auto pilot." Is your head starting to spin? Mine sure was.

A couple years ago, Brian developed the Woodpecker and proceeded to win several awards at Oshkosh, he reported. That machine was not sold either showing this is a fascination for achieving super-affordable and novel aircraft that meld full-scale, man-carrying aircraft to techniques employed in assembling RC aircraft. From the constant attention Lightning Bug generated, it is obvious I was not the only one wowed by this young man's design prowess and his unconventional approach. Bravo, Brian!

Fortunately, Brian consented to a video interview so you will get a fuller story after Videoman Dave gets the editing done.

Videoman Dave first pulled me aside to look at an unusual ultralight aircraft nestled in the homebuilt area hidden behind a row of porta-potties. It was a questionable (but, surprisingly not stinky) location for what I had to admit was one truly fascinating aircraft. Check out Lightning Bug! Sun ‘n Fun Paradise City volunteers and officials evidently agreed that Lightning Bug was too fun and too novel to be sequestered behind the biffies. Out it came to a prominent position right in front of the area headquarters tent. In this central spot, this sweet little flying creation steadily drew a crowd. I missed seeing Lightning Bug take to the air on Friday, April 7th, but I was told it looked good. This despite fairly strong winds that crossed the runway at angles approaching 90 degrees. Other light aircraft managed to fly normally so why does this surprise me? One look at the photos ought to explain but what you can’t see is that Lightning Bug weighs a mere 140 pounds and employs unorthodox control surfaces.

By Dan Johnson || Leave a Comment (Edit)

Here at the Sun ‘n Fun 2017 airshow LAMA’s LSA Mall is full and strong with 13 aircraft gathered from some of the leading brands. This exhibit was paired with the first-ever “Engines of Light Aircraft” display inside a large LAMA “Show Center” tent. On the first days of the Lakeland show, people appeared to be receiving the idea warmly.

One brand, Tecnam of Italy, showed its strength in the light aircraft community with three aircraft represented, two from First Landings at Apopka Airport in Florida and one from Lockwood Aircraft. The former are used in an active Sport Pilot school and the latter is a great example of the durability of Light-Sport Aircraft. The example from Lockwood has 4,500 hours on it and looks brand new.

Beside Tecnam, aircraft included Zlin’s Shock, BRM Aero’s Bristell, Progressive Aerodyne’s Searey, AeroJones’ CTLS, Pipistrel’s Virus SW, Aerotrek’s A-240, TL Ultralight’s Sting, Lockwood’s AirCam, and a Rans S-7 powered by Viking Engines.

Here at the Sun ‘n Fun 2017 airshow LAMA’s LSA Mall is full and strong with 13 aircraft gathered from some of the leading brands. This exhibit was paired with the first-ever “Engines of Light Aircraft” display inside a large LAMA “Show Center” tent. On the first days of the Lakeland show, people appeared to be receiving the idea warmly.

One brand, Tecnam of Italy, showed its strength in the light aircraft community with three aircraft represented, two from First Landings at Apopka Airport in Florida and one from Lockwood Aircraft. The former are used in an active Sport Pilot school and the latter is a great example of the durability of Light-Sport Aircraft. The example from Lockwood has 4,500 hours on it and looks brand new.

Beside Tecnam, aircraft included Zlin’s Shock, BRM Aero’s Bristell, Progressive Aerodyne’s Searey, AeroJones’ CTLS, Pipistrel’s Virus SW, Aerotrek’s A-240, TL Ultralight’s Sting, Lockwood’s AirCam, and a Rans S-7 powered by Viking Engines.

Engines on display include two examples of the Rotax 912, a Continental Titan X340, a Jabiru 2200, UL Power's UL260i, VIking's 130, and Hirth example of a two-stroke. All could be closely examined by visitors to the LAMA tent.

Here at the Sun ‘n Fun 2017 airshow LAMA’s LSA Mall is full and strong with 13 aircraft gathered from some of the leading brands. This exhibit was paired with the first-ever “Engines of Light Aircraft” display inside a large LAMA “Show Center” tent. On the first days of the Lakeland show, people appeared to be receiving the idea warmly. One brand, Tecnam of Italy, showed its strength in the light aircraft community with three aircraft represented, two from First Landings at Apopka Airport in Florida and one from Lockwood Aircraft. The former are used in an active Sport Pilot school and the latter is a great example of the durability of Light-Sport Aircraft. The example from Lockwood has 4,500 hours on it and looks brand new. Beside Tecnam, aircraft included Zlin’s Shock, BRM Aero’s Bristell, Progressive Aerodyne’s Searey, AeroJones’ CTLS, Pipistrel’s Virus SW, Aerotrek’s A-240, TL Ultralight’s Sting, Lockwood’s AirCam, and a Rans S-7 powered by Viking Engines.

By Dan Johnson || 2 Comments (Edit)

The big show at Lakeland, Florida is open and happening. Today (Tuesday April 4th) is opening day; the event runs through Sunday, April 9th. Along with Videoman Dave, we've already starting making the rounds and we've found plenty to see.

As you see in the photos, Evolution Trikes made a dramatic announcement of a new weight shift trike model called Revolt. In communications, they've spelled it RevoLT, which you could interpret to mean Revo (their super deluxe model) Light. Yet it's probably more correct to call it a different Revo without the fancy pants but with some cool new features.

The big show at Lakeland, Florida is open and happening. Today (Tuesday April 4th) is opening day; the event runs through Sunday, April 9th. Along with Videoman Dave, we've already starting making the rounds and we've found plenty to see.

As you see in the photos, Evolution Trikes made a dramatic announcement of a new weight shift trike model called Revolt. In communications, they've spelled it RevoLT, which you could interpret to mean Revo (their super deluxe model) Light. Yet it's probably more correct to call it a different Revo without the fancy pants but with some cool new features.

Among them, Revolt has giant tundra tires not often seen on trikes. Paired with that long shock absorber legs worthy of a SuperSTOL or Outback Shock. Like their lower priced single seater, Rev, Revolt does away with the forward strut, sometimes called a compression strut, which leaves both occupants but particularly the front occupant or solo pilot with an enormous unobstructed view.

Among them, Revolt has giant tundra tires not often seen on trikes. Paired with that long shock absorber legs worthy of a SuperSTOL or Outback Shock. Like their lower priced single seater, Rev, Revolt does away with the forward strut, sometimes called a compression strut, which leaves both occupants but particularly the front occupant or solo pilot with an enormous unobstructed view.

Revolt used power from the Rotax 912, which combined with an 18.7 gallon fuel tank, will provide a long range or at least plenty of local flying without refueling. The example showed at Sun 'n Fun had a 6-blade e-prop and ballistic parachute. The latter are optional extras by lead designer Larry Mednick (photo) explained that not many options were anticipated for the new model. It is aggressively priced — specifically to address those who found Revo a tad pricey — at $39,990 with the Rotax 582 engine, $49,990 with the 80-horsepower Rotax 912, or $52,990 for the 100 horsepower variant. This is tens of thousands less than a loaded Revo but the fun factor looks to be highly competitive.

Look for more in a video interview to follow.

Other stories we'll be following include the following but this list is hardly complete. Stay tuned for more fun in the sun in Lakeland.

Here are a few aircraft and developments we're tracking (more will follow when we discover them):

Revolt used power from the Rotax 912, which combined with an 18.7 gallon fuel tank, will provide a long range or at least plenty of local flying without refueling. The example showed at Sun 'n Fun had a 6-blade e-prop and ballistic parachute. The latter are optional extras by lead designer Larry Mednick (photo) explained that not many options were anticipated for the new model. It is aggressively priced — specifically to address those who found Revo a tad pricey — at $39,990 with the Rotax 582 engine, $49,990 with the 80-horsepower Rotax 912, or $52,990 for the 100 horsepower variant. This is tens of thousands less than a loaded Revo but the fun factor looks to be highly competitive.

Look for more in a video interview to follow.

Other stories we'll be following include the following but this list is hardly complete. Stay tuned for more fun in the sun in Lakeland.

Here are a few aircraft and developments we're tracking (more will follow when we discover them):

The big show at Lakeland, Florida is open and happening. Today (Tuesday April 4th) is opening day; the event runs through Sunday, April 9th. Along with Videoman Dave, we’ve already starting making the rounds and we’ve found plenty to see. As you see in the photos, Evolution Trikes made a dramatic announcement of a new weight shift trike model called Revolt. In communications, they’ve spelled it RevoLT, which you could interpret to mean Revo (their super deluxe model) Light. Yet it’s probably more correct to call it a different Revo without the fancy pants but with some cool new features. Among them, Revolt has giant tundra tires not often seen on trikes. Paired with that long shock absorber legs worthy of a SuperSTOL or Outback Shock. Like their lower priced single seater, Rev, Revolt does away with the forward strut, sometimes called a compression strut, which leaves both occupants but particularly the front occupant or solo pilot with an enormous unobstructed view.

By Dan Johnson || Leave a Comment (Edit)

A year and a half of planning, adjusting, and engineering have resulted in the pages you see now. We hope you like it and it will only get better. Image thanks to Shark designer, Jaro Dostal

Here are a few website user notes...

(1) All current members (those who help us provide this content by contributing $29 a year) or registered visitors (those leaving an email address) will have to reset their password. You may be used to this on other updated websites. That’s because a change of servers and web platforms demands it. (2) Search will soon add an “advanced” feature to help you look through our enormous database to find more specific information. For now, Search finds any reference to the letters you type. This will get you most of what you are seeking. Like new smartphone software, we’ll keep making improvements. Since we refer to the project as BDJ2, I guess it will be BDJ2.1… BDJ2.2, and so on. (3) Some pages are not complete as of this "beta launch." Those include PlaneFinder 2.0, LSA Market Info, and others. We'll get to them as quickly as we can, however...

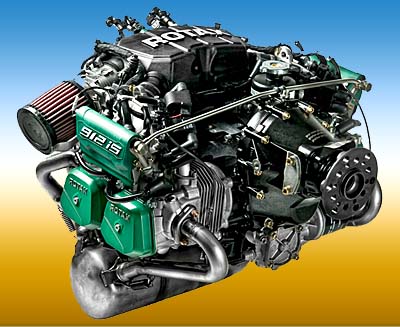

Under the shiny cowling is a ton of detail that most folks never see. While we tweak and adjust we hope you'll bear with us.

You could call it thirteen years in the making. More pragmatically, ByDanJohnson.com has now caught up with the mobile revolution. Welcome to ByDanJohnson.com 2.0 (or, for short, “BDJ2”). We hope you’ll like the changes — and will not be temporarily frustrated with the differences from the old “BDJ1” site — because even more changes are on the way. You may not believe it looks too different… and if so, that’s good. We tried to keep most of the look and feel even while making the website much more mobile-friendly, or “responsive” in the parlance of tech folks. With two thirds of our website visitors coming via their smartphone, the site is mainly different in how well it accommodates whatever modern device is used to view the articles, videos, and more. Here are a few website user notes… (1) All current members (those who help us provide this content by contributing $29 a year) or registered visitors (those leaving an email address) will have to reset their password.

By Dan Johnson || Leave a Comment (Edit)

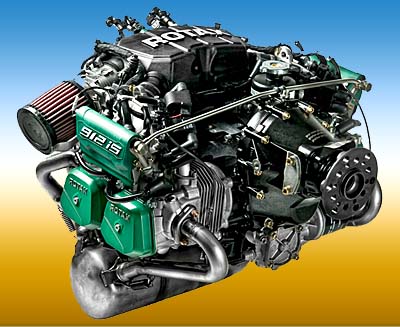

How is it that Rotax so dominates the supply of engines to light aircraft? Many reasons might be cited but one is the superlative training they offer. For 2017, the company is going even further, now offering essential training opportunities to the legions who attend airshows in both the USA and Europe.

How is it that Rotax so dominates the supply of engines to light aircraft? Many reasons might be cited but one is the superlative training they offer. For 2017, the company is going even further, now offering essential training opportunities to the legions who attend airshows in both the USA and Europe.

Rotax makes high power-to-weight ratio powerplants that fit in smaller cowlings. Liquid cooling addresses the challenges of keeping motors from overheating, especially in those in tighter engine compartments. Rotax engines are modern and they keep updating them. They can produce in higher volumes than some competitors, have highly regarded quality control, and their testing facility is state-of-the-art. These reasons and more explain the estimate 75% or higher market share the Austrian company enjoys.

The Austrian engine maker said that during Sun 'n Fun 2017 the Rotax Flying and Safety Club (RFSC) and BRP-Rotax will offer information sessions conducted by experienced RFSC instructors.

The special workshops are addressed to those who would like to learn more about Rotax aircraft engines in general and about the 100-horsepower Rotax 912 iS Sport aircraft engine installation in particular.

"Three different types of information sessions will be offered at booth SE15 near the main entrance gate," said a Rotax spokesperson. Throughout the week Sun 'n Fun attendees can register to attend one of the RFSC sessions right at the company's booth, however, they note seating is limited so they recommend interested parties reserve space early.

Rotax's Sun 'n Fun exhibit can be found just inside the main entrance gate for the Lakeland show.

On Tuesday to Friday from 1:00 to 2:00 PM, kit builders or aircraft developers considering use of the newer fuel-injected Rotax 912 iS Sport engine can attend the "Rotax 912iS Installation Information" session. This session is also free.

Professionals who work on Rotax engines for compensation can take a "RFSC independent Rotax Maintenance Technician (iRMT) Renewal Course" on Thursday April 6th from 8:00 AM to 5:00 PM. RFSC will cover Rotax 2-stroke maintenance tips.

Further workshops related to Rotax engines will be offered by Lockwood Aviation at Paradise City's forums area. Lockwood will present two iRMT Renewal Courses.

The first will be Wednesday April 5th from 10:30 to 11:45 AM covering "Rotax 2-stroke engine maintenance tips" while the second occurs on Thursday, April 6th from 10:30 to 11:45 AM covering "Rotax 912 / 914 service & operating tips." For these iRMT Renewal Courses please contact Lockwood Aviation at 863-655-5100.

At the same time as Sun 'n Fun is ongoing, the Aero Friedrichshafen's 25th anniversary 2017 event will be held in the picturesque town in the far south of Germany. Rotax will also offer training at this event.

Sessions are scheduled for Wednesday and Friday (5 and 7 April) from 1300 to 1500 offered in English; and on Thursday and Saturday (6 and 8 April) from 1300 to 1500 offered in German. All sessions are held in Room Schwarzwald.

Rotax is offering aircraft maintenance training at both Sun 'n Fun and Aero Friedrichshafen 2017; the shows occur concurrently this year.

Rotax is a major player in aircraft engines and the dominant producer for light aircraft. "With more than 175,000 engines sold in 40 years, Rotax aircraft engines lead the Light-Sport and ultralight aircraft market." The Austrian company has 19 authorized distributors and a network of more than 220 points of sale and repair centers supporting customers worldwide. "Rotax aircraft engines are supplied to more than 80% of all aircraft manufacturers in its segment," said the company's spokesperson.

Rotax also announced a new owner registration system. Why might this be important to operators of Rotax engines in the majority of LSA and many light kit aircraft?

"This new paperless engine registration process offers various advantages for Rotax aircraft engine owners," said the company. They listed three worthy reasons: (1) Rotax wants to know their customers and how their engines are operated; (2) customers who opt-in receive newsletters and new technical documentation directly from the manufacturer; and, (3) "In case of a reported engine theft, re-registration of this engine will be impossible." That might not get a stolen engine back but it may help deter theft in the first place.

Convinced? You should be. Go here to register.

How is it that Rotax so dominates the supply of engines to light aircraft? Many reasons might be cited but one is the superlative training they offer. For 2017, the company is going even further, now offering essential training opportunities to the legions who attend airshows in both the USA and Europe. Rotax makes high power-to-weight ratio powerplants that fit in smaller cowlings. Liquid cooling addresses the challenges of keeping motors from overheating, especially in those in tighter engine compartments. Rotax engines are modern and they keep updating them. They can produce in higher volumes than some competitors, have highly regarded quality control, and their testing facility is state-of-the-art. These reasons and more explain the estimate 75% or higher market share the Austrian company enjoys. The Austrian engine maker said that during Sun ‘n Fun 2017 the Rotax Flying and Safety Club (RFSC) and BRP-Rotax will offer information sessions conducted by experienced RFSC instructors.

By Dan Johnson || Leave a Comment (Edit)

"It cannot be done," is the quick dismissal from many in aviation, referring to instrument flying in a LSA. In 2017, I venture to say everyone in aviation (worldwide) knows about Light-Sport Aircraft and the Sport Pilot certificate, but a superficial knowledge can be a bad thing. The details unveil more.

"It cannot be done," is the quick dismissal from many in aviation, referring to instrument flying in a LSA. In 2017, I venture to say everyone in aviation (worldwide) knows about Light-Sport Aircraft and the Sport Pilot certificate, but a superficial knowledge can be a bad thing. The details unveil more.

Think about IFR in an LSA this way: Can you fly IFR in a homebuilt aircraft? Can you do so in a Cessna 172? Does it matter that these two distinct types have not gone through a thorough IFR evaluation by FAA? If you know those answers then why should such flying be prevented in LSA?

It's true, the industry committee called ASTM F.37 issued advice on this subject to LSA producers. F.37 is the group that has labored for a dozen years to provide FAA with industry consensus standards allowing FAA to "accept" (not "certify") SLSA. The group has been working on a IFR standard for some time without arriving at consensus. Partly because the work is not done the committee urged manufacturers not to openly sell IFR capability until the standard was in place and accepted by FAA. (The agency accepts standards and aircraft under different processes.)

F.37's advice is directly related to a present lack of such a standard and possible resistance from legacy aircraft producers. However, neither the committee's advice nor the regulation creating SP/LSA prevents you from filing IFR. Instead yes-or-no relates to a manufacturer's preference plus written FAA-issued operating limitations.

So, as some say, it cannot be done, right? Wrong.

So, as some say, it cannot be done, right? Wrong.

Bristell USA, importers of the superlative LSA of the same name built in the Czech Republic by BRM Aero, has a different approach. They use the ELSA opportunity.

An Experimental LSA starts out as a bolt-for-bolt copy of the SLSA version. Once issued its airworthiness certificate the owner can elect changes. He or she may not use an ELSA for compensated flight instruction or rental, but in other ways, they are significantly the same airplane. Am ELSA owner can change panel gear and other components (even including the engine) and need not seek permission for each change from the manufacturer.

Rather than repeat facts already reported here, I refer you to these articles: "A Raging Debate... IFR, IMC, VMC, and LSA" — "IFR and LSA: Much Ado About... What?" — "IFR 'Certification' of Avionics" — and, for those who want to examine FAA's exact words, go to "FAR Part 91.205 (required equipment for IFR)".

At Sebring 2017, I flew with Bristell USA's John Rathmell. John is not only a highly experienced pilot, he is knowledgeable about Bristell's IFR option. In our video shown below, I asked John to cover some of this detail for you and he was most accommodating.

At Sebring 2017, I flew with Bristell USA's John Rathmell. John is not only a highly experienced pilot, he is knowledgeable about Bristell's IFR option. In our video shown below, I asked John to cover some of this detail for you and he was most accommodating.

Now, I understand plenty of readers of this website or viewers of the many videos produced by Videoman Dave and myself perhaps do not care a whit about flying IFR. If you fly strictly for fun in nice weather, good for you! Have at it and enjoy! Yet, if you like the versatility of IFR, it is possible.

To fly under IFR rules, the pilot must have an IFR rating on his or her Private or better pilot certificate, that person must be current in those skills, and the airplane must be qualified by the means referenced above and maintenance must be up-to-date. You cannot — and more importantly should not — go fly into clouds simply because you have wonderful equipment on board from companies like Dynon, Garmin, or MGL.

In summary, if you are an instrument pilot, and if you are current, and if you have a medical, and if you purchase an aircraft like the Bristell and register it as an ELSA, no regulation prevents you from filing and flying IFR including into IMC. Only you can judge if that is a smart activity for you, and I hope you'll do so wisely.

Hear more about IFR in a Bristell and join John and I for a flight in this gorgeous, well flying Light-Sport Aircraft in the following video:

“It cannot be done,” is the quick dismissal from many in aviation, referring to instrument flying in a LSA. In 2017, I venture to say everyone in aviation (worldwide) knows about Light-Sport Aircraft and the Sport Pilot certificate, but a superficial knowledge can be a bad thing. The details unveil more. Think about IFR in an LSA this way: Can you fly IFR in a homebuilt aircraft? Can you do so in a Cessna 172? Does it matter that these two distinct types have not gone through a thorough IFR evaluation by FAA? If you know those answers then why should such flying be prevented in LSA? It’s true, the industry committee called ASTM F.37 issued advice on this subject to LSA producers. F.37 is the group that has labored for a dozen years to provide FAA with industry consensus standards allowing FAA to “accept” (not “certify”) SLSA. The group has been working on a IFR standard for some time without arriving at consensus.

By Dan Johnson || Leave a Comment (Edit)

We lost one of the good ones recently. You may not have met or even know this man, but you certainly know — and may absolutely love — the airplanes he created.

We lost one of the good ones recently. You may not have met or even know this man, but you certainly know — and may absolutely love — the airplanes he created.

We say a sad and final farewell to Professor Luigi "Gino" Pascale.

While it is somewhat melancholy to bid farewell to this man of short stature but giant achievements, he did what he loved for seven decades and until very near the time of his death. None of us can ask for much more than that.

Luigi is also succeeded by family members who continue to run and expand the operation he began with his brother Giovanni so many years ago. Officially he was chief preliminary design officer of Costruzioni Aeronautiche Tecnam but Tecnam team members remember him fondly as the heart and soul of Tecnam. He was 93 at his passing.

Professor Luigi — as I heard several Tecnam employees refer to him — got his start in aviation designing model airplanes way back in the 1930s. His brother Giovanni and he were passionate about flight and never stopped pursuing the dream.

The Pascale brothers began work on their first full-sized airplane in 1948. They called it the P48 Astore. On the 65th anniversary of that modest beginning, the now-giant of light aviation called Tecnam, unveiled a brand new version of Astore (reported here). Of course, Professor Luigi had a great deal to do with this one as he did with the first. Subsequently all Tecnam designs have the designation P##, with the numbers representing the year the design was started.

Luigi Pascale poses in front of the Tecnam Twin, one of his many designs.

Perhaps his most famous design — at least prior to the Light-Sport Aircraft of more recent years — was the Partenavia, a sleek twin-engine general aviation airplane started in 1957. Before that he and his brother created numerous race planes. Sport and recreational flying never left his mind and Sport Pilots today benefit from his tireless work. Indeed, the original company and the one we know today as Tecnam has produced and sold more than 7,000 aircraft, the company reported.

Perhaps his major success — from a number produced standpoint — is his P92, a two-seat metal airplane that has been delivered in several variations. This wonderful light aircraft remains the company's most popular design. After 25 years of service, more than 2,500 are flying in many, many countries around the planet.

While no one knows for sure, it would not be too much of a stretch to say P92 is the most successful Light-Sport Aircraft ever built (though not all models precisely meet the LSA description). That many airplanes flown an uncounted number of hours have delivered many smiles to many pilots regardless of the language they speak.

Luigi Pascale pictured with his nephew, Paolo Pascale. In this video, hear Paolo describe the new Astore and refer to his uncle.

"Luigi was incredibly proud of Tecnam and all of its employees, and we will all miss him greatly," said Paolo Pascale, who these days is Tecnam's CEO. "His drive to excellence, determination, can-do spirit and commitment to our company will inspire and stay with us always."

Luigi accomplished much and his family of both relatives and company team members have much to be proud of and the pilots who continue to fly his design join with the family in bidding a fond farewell to the talented gentleman from Italy.

See Professor Luigi's heartfelt appreciation when he won the LAMA President's Award for 2016. It is clear he loved aviation and those who loved it with him:

We lost one of the good ones recently. You may not have met or even know this man, but you certainly know — and may absolutely love — the airplanes he created. We say a sad and final farewell to Professor Luigi “Gino” Pascale. While it is somewhat melancholy to bid farewell to this man of short stature but giant achievements, he did what he loved for seven decades and until very near the time of his death. None of us can ask for much more than that. Luigi is also succeeded by family members who continue to run and expand the operation he began with his brother Giovanni so many years ago. Officially he was chief preliminary design officer of Costruzioni Aeronautiche Tecnam but Tecnam team members remember him fondly as the heart and soul of Tecnam. He was 93 at his passing. Professor Luigi — as I heard several Tecnam employees refer to him — got his start in aviation designing model airplanes way back in the 1930s.

By Dan Johnson || 6 Comments (Edit)

Quicksilver made perhaps the most successful kit in aviation history, with more than 15,000 completed and flying. All photos by James Lawrence

Quicksilver Aeronautics achieved Special LSA status for their side-by-side two seater, Sport 2SE.

Way back in 1993, Quicksilver won the very first Primary Category approval from FAA. That program never got any legs and the company sold few with this registration.

One of the major stumbles in the light aircraft world was the closure of Quicksilver Aeronautic’s southern California factory in Temecula. That ended a long-running era dating back to the 1970s. See articles here and here. Plenty of folks expressed concern. Their worry was warranted. As a kit supplier, Quicksilver was one of the most prolific in aviation history with more than 15,000 kits delivered, nearly every one of which got airborne after the short build time. Some have been retired due to age, accident, or neglect, but many thousands continue to fly. What happens when that large fleet can no longer buy parts? With the factory closed, are all those owners orphaned, having no factory-fresh parts available? Don’t worry, be happy (so the song said). “We currently have all the Quicksilver parts in stock and are shipping mass quantities daily,” said Gene “Bever” Borne, of Air-Tech, Inc.

By Dan Johnson || Leave a Comment (Edit)

We are fast approaching an important time of year... only this year I am a bit conflicted. The good news is Sun 'n Fun and Aero Friedrichshafen are terrific shows. I have been attending both for more years that I care to admit. (OK, I guess I don't ming saying Aero 2016 was my 20th in a row. I've been going to Sun 'n Fun so long, it makes me feel old to say how many years it has been.)

We are fast approaching an important time of year... only this year I am a bit conflicted. The good news is Sun 'n Fun and Aero Friedrichshafen are terrific shows. I have been attending both for more years that I care to admit. (OK, I guess I don't ming saying Aero 2016 was my 20th in a row. I've been going to Sun 'n Fun so long, it makes me feel old to say how many years it has been.)

Both events are vitally important to the light aircraft space I enjoy and as steadily reported on this website. Both have strong sectors serving Light-Sport Aircraft (and in Europe, LSA-like aircraft) plus light kit-built aircraft and ultralight aircraft (in Europe called 120-kilogram class or SSDR, which means Single Seat De-Regulated).

These classes of aircraft are the ones I love to report and probably the ones you also enjoy.

The bad news and the source of my conflict is that this year, the two shows runs concurrently... darn it! Because "Beam-me-up-Scotty technology has yet to be developed, I have zero way to attend both. Fortunately, I have a plan.

As noted in the "Welcome" text above, I will cover Sun 'n Fun 2017 and my fellow publisher, Roy Beisswenger of Powered Sport Flying will attend and cover Aero 2017 for ByDanJohnson.com. Thanks, Roy!

I'm irked I cannot attend Aero this year for another reason: it is the 25th anniversary event. Organizer and Aero project leader, Roland Bosch, said, "The entire spectrum of modern ultralights, gliders, and [larger] aircraft, as well as business jets, will be exhibited at the show." I enjoy his leading emphasis on the light side, where Aero truly got its start a quarter century ago. Roland also noted the e-flight air show taking place one day before the opening of the anniversary Aero. "We want to give you exciting insights into the world of flight and offer you the opportunity to talk with experts."

I'm irked I cannot attend Aero this year for another reason: it is the 25th anniversary event. Organizer and Aero project leader, Roland Bosch, said, "The entire spectrum of modern ultralights, gliders, and [larger] aircraft, as well as business jets, will be exhibited at the show." I enjoy his leading emphasis on the light side, where Aero truly got its start a quarter century ago. Roland also noted the e-flight air show taking place one day before the opening of the anniversary Aero. "We want to give you exciting insights into the world of flight and offer you the opportunity to talk with experts."

What I consider to be the largest, more interesting show in Europe is up in exhibitor bookings for 2017. More than 630 are expected. They welcome back GA heavyweight Diamond but more important to our readers, Tecnam will be back after an absence of two or three years.

Tecnam will be showing off their supersized Traveler, an 11-seater aimed at the regional airline market, but they will also be showing their new version of the Sierra, the Mark 2. In a reversal of the usual situation, Americans have already seen this one, just a few weeks ago at Sebring 2017. Now, Europeans will get to examine the newest member. Tecnam has larger aircraft, certainly, but they are still most attentive to the LSA market, where their numbers remain strong.

German LSA producer, Remos debuted their superb GXiS at Aero 2016 last year. It was a pleasure to see this handsome aircraft again displayed after the Pasewalk-based company recovered from their court-ordered reorganization. Remos appears financially healthy again and their aircraft has long been one I admired. See this article for more thoughts on how it flies.

REMOS GXiS

Continuing their pilot-friendly refinement of this already impressive aircraft, engineers will unveil a new "jet throttle" in the center console that combines the control of power and wheel brakes in one lever. See more and talk to the team at Aero in Hall B3, Booth 107. The B1-2-3-4 halls, each the size of a gymnasium (see arrow), contain most of the aircraft we cover on this website although a few are located in the southern row of A Halls.

With 50 employees, Remos builds GXiS and GXNXT (called GXnXES in American). These flying machines reside in 1,320-pound (600 kg) LSA category and in the European ultralight category that maxes out at 472.5 kilograms (1,040 pounds) gross. The company reports more than 450 Remos models are flying all over the world with about 120 in the USA.

We are fast approaching an important time of year… only this year I am a bit conflicted. The good news is Sun ‘n Fun and Aero Friedrichshafen are terrific shows. I have been attending both for more years that I care to admit. (OK, I guess I don’t ming saying Aero 2016 was my 20th in a row. I’ve been going to Sun ‘n Fun so long, it makes me feel old to say how many years it has been.) Both events are vitally important to the light aircraft space I enjoy and as steadily reported on this website. Both have strong sectors serving Light-Sport Aircraft (and in Europe, LSA-like aircraft) plus light kit-built aircraft and ultralight aircraft (in Europe called 120-kilogram class or SSDR, which means Single Seat De-Regulated). These classes of aircraft are the ones I love to report and probably the ones you also enjoy.

By Dan Johnson || Leave a Comment (Edit)

Although some aircraft were pretty sleek and cool as the new millennia arrived (such as the handsome Thundergull with developer Mark Bierle flying), a host of new brands descended upon aviation. Today you know them; in 2004, not so much.

Of, course, since ByDanJohnson.com has been live for 13 years (almost to the day, which will be April 1st, 2017), this website preceded social media and even giants like YouTube. The website you have been so loyally visiting was assembled using the fairly crude tools available at the beginning of this new millennia. However, now that we are 17 years into the new century, it is time for a change... a BIG change.

In just a few days, after we check and recheck, adjust and tweak, we will hit the button for our "beta launch" of an entirely new look and feel.

As BDJ1.0 launched back in April of 2004, we had aircraft like this Drifter on Lotus amphib floats (flown by gurus Phil Lockwood and Jeff Hudson) powered by the two-stroke Rotax 582.

Most humans, myself included, are not always comfortable with change. While the new look — which new webmaster Russell Kasselman (of Iron Dog Media) and I abbreviate as "BDJ2.0" — will contain all the material you want most but it will not be 100% complete when it launches.

Oh, don't worry. BDJ2.0 will have all the news and video you have come to love in the last few years since video swaggered onto the stage. We definitely will get every aspect of the old site ported over to the new during the month of March. By our "grand launch" — hopefully by the April 1st 13th anniversary of the original website — you should find everything you ever sought on the old site.

Back in 2006, I traveled to Connecticut to fly an old favorite — the Flightstar II powered by a four-stroke HKS — with a longtime friend in the business, Tom Peghiny. My smile shows how I felt about it.

But BDJ2.0 will be different to use. I hope you will tell us what you like or don't like. We do this for you so we want it to work well. With literally millions of words, more than 100,000 images, thousands of articles, and hundreds of videos, plus one-of-a-kind features like PlaneFinder 2.0, our popular SLSA List, our resource-rich FIRM List, LSA Market Info, and the most informative advertisements you can find anywhere in aviation... (whew!) it has been been a major undertaking. We've been at this for 18 months and, truly, the work is never really done because the world of tech changes even faster than the world of affordable aviation.

Please stay with us as the "great ride" continues. I so sincerely appreciate each and every visitor. We love what we do and we hope it shows!

* Google's vaunted page ranking system highly values websites that are "responsive" but since we are launching a fresh site based on new servers, our ranking may suffer for a short period. In days or weeks, we think we will regain our high position on a Google search once their robots have thoroughly scoured BDJ2.0.

For thirteen years, ByDanJohnson.com has served the light aircraft community, covering Light-Sport Aircraft, light kit-built aircraft, and ultralight aircraft. Along the way, we’ve covered all manner of interesting light aircraft from the tiniest drones to the emerging new-style certified GA aircraft from producers of LSA. As my outgoing webmaster said, “It’s been quite a ride!” Of, course, since ByDanJohnson.com has been live for 13 years (almost to the day, which will be April 1st, 2017), this website preceded social media and even giants like YouTube. The website you have been so loyally visiting was assembled using the fairly crude tools available at the beginning of this new millennia. However, now that we are 17 years into the new century, it is time for a change… a BIG change. In just a few days, after we check and recheck, adjust and tweak, we will hit the button for our “beta launch” of an entirely new look and feel.

By Dan Johnson || Leave a Comment (Edit)

Once upon a time, the producer of a yellow LSA taildragger installed the industry's most powerful engine resulting in a performance leader. This gambit succeeded handily and the builder enjoyed several strong years of sales. Others looked upon this success and saw that it was good.

Once upon a time, the producer of a yellow LSA taildragger installed the industry's most powerful engine resulting in a performance leader. This gambit succeeded handily and the builder enjoyed several strong years of sales. Others looked upon this success and saw that it was good.

So, of course, being aviation entrepreneurs, others worked to do the original one better. How about not only an excess of power but other features and macho good looks to cause jaw-drops at every airshow? You may believe I am writing about Just Aircraft and their magnificent SuperSTOL. I've enjoyed flying this aircraft and you can research it further here.

Adding exceptional wing qualities to a potent engine results in a sub-market within the LSA sector that has been drawing strong interest and the sales that follow. With newcomers offering appealing features and reducing the price into more affordable realms, it's not hard to see why pilots are learning about these new flying machines and bringing one home.

Into the cauldron of development activity stepped Zlin and their Shock model. This Czech-based company is no newcomer. You already know their Savage models, reported here frequently as the former iCub and later the Outback and Nomad plus the one-of-a-kind Bobber.

Into the cauldron of development activity stepped Zlin and their Shock model. This Czech-based company is no newcomer. You already know their Savage models, reported here frequently as the former iCub and later the Outback and Nomad plus the one-of-a-kind Bobber.

With advice and suggestions from SportairUSA proprietor Bill Canino — himself already a highly skilled veteran of the SP/LSA movement — Zlin took the model SportairUSA sells as the Outback and added what Bill calls "the Shock options." He words it that way because these fresh features can be retrofitted to earlier Outbacks. In addition, the auto-functioning leading edge slats can be removed (with only eight bolts) translating to great versatility.

Custom hydraulic, side-mounted shock absorbers with 12 inches of travel and suspension geometry integrated into main and tail landing gear virtually eliminates the problems of touchdown rebound and ground hop that are all too common with traditionally sprung cabane-style landing gear. The gear position is also moved forward to enhance braking capacity with less risk of overturning. As a result, the Outback Shock lands and taxis with remarkable control and stopping power. The tailwheel is also shock absorbed.

Looking deeper into the details, the Shock options include what SportairUSA calls the "hyper-STOL" wing profile boasting short takeoff and faster rate of climb. This incorporates slatted wings that move according to airflows without pilot involvement combined with two-element Fowler flaps and strategically placed vortex generators in numerous locations to optimize low-speed control.