Lined up on the runway, I open the throttle to the stop. The Dynamic surges forward, my right thumb presses a small button at the base of the throttle quadrant and I push the lever further forward. In an instant there’s 15% more thrust and the speed tape really starts to roll. Ease back on the stick and we’re airborne after a very short ground roll and climbing away at well over 1200 fpm. Flaps up, and 20 seconds later we’re passing through 400 feet, I pull the power back past the detent and the turbocharger control unit (TCU) reduces boost to 35 inches of manifold pressure. I then lower the nose, dial the prop rpm down to 5500 engine rpm and note the VSI is still showing around 1000 fpm before swinging the shapely spinner onto a south-easterly heading. Already I can see that the field of view is phenomenal and feel that the handling is crisp and taut.

Lined up on the runway, I open the throttle to the stop. The Dynamic surges forward, my right thumb presses a small button at the base of the throttle quadrant and I push the lever further forward. In an instant there’s 15% more thrust and the speed tape really starts to roll. Ease back on the stick and we’re airborne after a very short ground roll and climbing away at well over 1200 fpm.

Lined up on the runway, I open the throttle to the stop. The Dynamic surges forward, my right thumb presses a small button at the base of the throttle quadrant and I push the lever further forward. In an instant there’s 15% more thrust and the speed tape really starts to roll. Ease back on the stick and we’re airborne after a very short ground roll and climbing away at well over 1200 fpm.

I’d seen the full-size Stampe SV4-RS replica at AERO a few weeks previously, and it really put a hook in me. I was fortunate enough to fly a Stampe several years ago and was very impressed—it being greatly superior to the DH Tiger Moth, with which it is often confused. Of course, even the youngest Stampe is still 69 years old, and they require a lot of maintenance. Spares for the original Renault engine in particular are getting rare, the strength of the wooden fuselage can be compromised from decades of oil being splattered across it and the metal fixtures and fittings are far from the first flush of youth. These are old aircraft and they require a lot of looking after. Indeed, the reason why such aircraft (and cars and motorbikes of a similar vintage) are often referred to as “collector’s machines” is that you often need someone following along behind collecting up all the pieces that have fallen off! (A slight exaggeration but you get my drift).

I’d seen the full-size Stampe SV4-RS replica at AERO a few weeks previously, and it really put a hook in me. I was fortunate enough to fly a Stampe several years ago and was very impressed—it being greatly superior to the DH Tiger Moth, with which it is often confused. Of course, even the youngest Stampe is still 69 years old, and they require a lot of maintenance. Spares for the original Renault engine in particular are getting rare, the strength of the wooden fuselage can be compromised from decades of oil being splattered across it and the metal fixtures and fittings are far from the first flush of youth. These are old aircraft and they require a lot of looking after. Indeed, the reason why such aircraft (and cars and motorbikes of a similar vintage) are often referred to as “collector’s machines” is that you often need someone following along behind collecting up all the pieces that have fallen off! (A slight exaggeration but you get my drift).

“Look at that groundspeed!” I exclaimed, pointing at the Garmin EFIS. “Our TAS is nearly 125 knots, which means we’ve got a 60 knot headwind straight on the spinner!” “Can you imagine being up here in a traditional microlight?” asked the Sting’s owner, John Palmer. “No, because not only would I be scared out of my mind at the prospect of having to land, but right now we’d practically be going backwards!” I said.

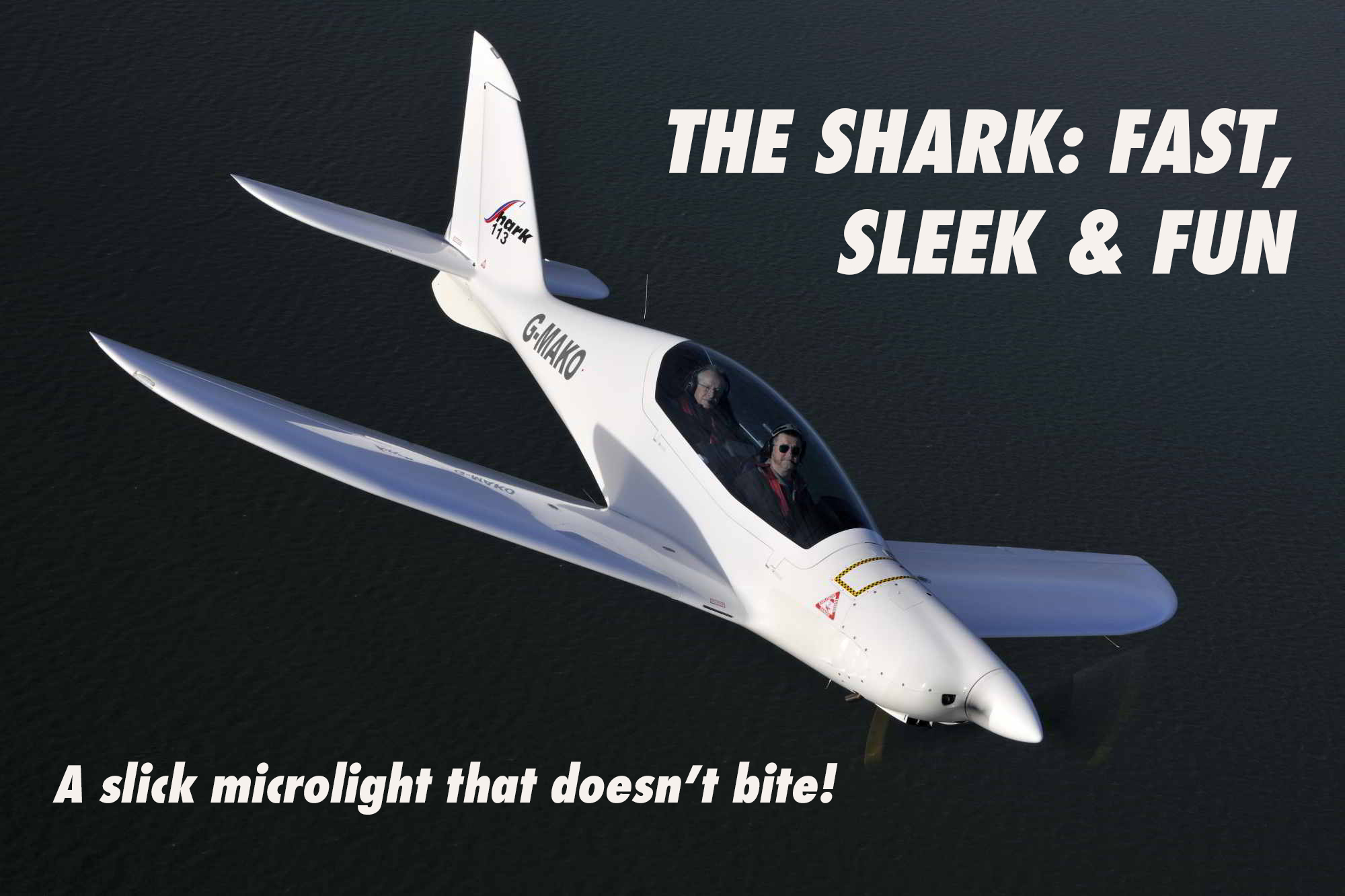

I’ve written before about just how capable and potent the new breed of light sport microlights is, and several of the aircraft I’ve tested recently are not only comparable to traditional GA types, but are demonstrably superior. An excellent representative of this new breed of speedy sport planes is the

“Look at that groundspeed!” I exclaimed, pointing at the Garmin EFIS. “Our TAS is nearly 125 knots, which means we’ve got a 60 knot headwind straight on the spinner!” “Can you imagine being up here in a traditional microlight?” asked the Sting’s owner, John Palmer. “No, because not only would I be scared out of my mind at the prospect of having to land, but right now we’d practically be going backwards!” I said.

I’ve written before about just how capable and potent the new breed of light sport microlights is, and several of the aircraft I’ve tested recently are not only comparable to traditional GA types, but are demonstrably superior. An excellent representative of this new breed of speedy sport planes is the  The flaps retract quickly with no discernible change in pitch, and I point the shapely spinner towards Fenland. It’s a Jekyll and Hyde day. Below the clouds it’s gray and bumpy, but above them it's smooth and sunny, while the strong tailwind is giving us a very impressive groundspeed.

Fenland quickly appears, we can see the Cessna 172 photo ship climbing away right on schedule. I’m soon slotting the Sting neatly into echelon port. Photographer Keith Wilson opens his window, and we’re off.

Initially all goes well, but remember what I said earlier about pride coming before a call? The stick top is liberally studded with six switches and buttons, and while replying to C172 pilot Steve Brown, I accidentally changed frequencies! That minor SNAFU aside, this is a fun shoot. It's nice and smooth above the clouds, with great visibility and beautiful light. Steve flies a smooth lead, and the fantastic field of view provided by the big bubble canopy, crisp handling and constant-speed prop ensure the shoot is completed quickly—which is just as well, as the wind has blown us almost to Norfolk.

As is often the case, the formation work has already told me what I need to know about the control response and harmony. They really are excellent, with authoritative ailerons, an effective elevator and influential rudder. The ailerons and elevator are actuated by pushrods—and you can tell. It’s very crisp in pitch and roll but not twitchy. It has the ideal blend of control and stability.

It's maneuverable when you want it to be, and stable when you don’t, although I note an interesting anomaly. When turning tight to port, there’s a subtle but definite rumble through the stick.

Breakout forces are low, and the roll rate rapid, with a 45-45° reversal taking less than two seconds. There is negligible adverse yaw. The stick-free stability is exactly as I remember it, being a little weak directionally (in yaw), positive longitudinally and neutral laterally. The soft directional stability is typical of many light aircraft fitted with large nosewheel spats, as there’s often not a lot of side-area aft of the center of pressure.

Slowing down for some stalls reinforces that the Sting is as slippery as it looks, as it decelerates quite slowly even with the throttle at idle and the prop set fairly fine. All the stalls are very benign. With flaps up or down, throttle closed or wide open—there are no alarming attributes or unpleasant peculiarities, and to recover, just lower the nose and the wing begins flying again almost instantly, with minimal height loss. With the flaps down the deck angle is just preposterously precipitous. You’d have to be asleep to inadvertently stall it.

At such high angles of attack, position error makes the ASI unreliable, but the book speed of 43 knots IAS seems perfectly plausible. However—and again this is a trait it shares with many similar types, the flap-extension speed is quite low at only 65 knots. On a day with any real wind, 60 knots is a sensible speed on final, and if you decide to go around, you need to pitch up and reconfigure quickly to avoid busting the Vfe.

The flaps retract quickly with no discernible change in pitch, and I point the shapely spinner towards Fenland. It’s a Jekyll and Hyde day. Below the clouds it’s gray and bumpy, but above them it's smooth and sunny, while the strong tailwind is giving us a very impressive groundspeed.

Fenland quickly appears, we can see the Cessna 172 photo ship climbing away right on schedule. I’m soon slotting the Sting neatly into echelon port. Photographer Keith Wilson opens his window, and we’re off.

Initially all goes well, but remember what I said earlier about pride coming before a call? The stick top is liberally studded with six switches and buttons, and while replying to C172 pilot Steve Brown, I accidentally changed frequencies! That minor SNAFU aside, this is a fun shoot. It's nice and smooth above the clouds, with great visibility and beautiful light. Steve flies a smooth lead, and the fantastic field of view provided by the big bubble canopy, crisp handling and constant-speed prop ensure the shoot is completed quickly—which is just as well, as the wind has blown us almost to Norfolk.

As is often the case, the formation work has already told me what I need to know about the control response and harmony. They really are excellent, with authoritative ailerons, an effective elevator and influential rudder. The ailerons and elevator are actuated by pushrods—and you can tell. It’s very crisp in pitch and roll but not twitchy. It has the ideal blend of control and stability.

It's maneuverable when you want it to be, and stable when you don’t, although I note an interesting anomaly. When turning tight to port, there’s a subtle but definite rumble through the stick.

Breakout forces are low, and the roll rate rapid, with a 45-45° reversal taking less than two seconds. There is negligible adverse yaw. The stick-free stability is exactly as I remember it, being a little weak directionally (in yaw), positive longitudinally and neutral laterally. The soft directional stability is typical of many light aircraft fitted with large nosewheel spats, as there’s often not a lot of side-area aft of the center of pressure.

Slowing down for some stalls reinforces that the Sting is as slippery as it looks, as it decelerates quite slowly even with the throttle at idle and the prop set fairly fine. All the stalls are very benign. With flaps up or down, throttle closed or wide open—there are no alarming attributes or unpleasant peculiarities, and to recover, just lower the nose and the wing begins flying again almost instantly, with minimal height loss. With the flaps down the deck angle is just preposterously precipitous. You’d have to be asleep to inadvertently stall it.

At such high angles of attack, position error makes the ASI unreliable, but the book speed of 43 knots IAS seems perfectly plausible. However—and again this is a trait it shares with many similar types, the flap-extension speed is quite low at only 65 knots. On a day with any real wind, 60 knots is a sensible speed on final, and if you decide to go around, you need to pitch up and reconfigure quickly to avoid busting the Vfe.

The two Chinese RX-1E-A machines from Rhyen Aircraft Industry Co. Ltd were particularly interesting, as they were fitted with batteries that could be quickly and easily removed and exchanged for freshly charged ones. Of course, there’s always a downside: Quickly replaceable batteries are a great idea, until they get dropped. That could be a very expensive mistake! Secondly they can’t be liquid-cooled and having flight-tested two electric aircraft I’m very aware just how important monitoring the temperature of the batteries is. Air-cooling lithium-ion batteries really doesn’t cut it in my experience. Or does the Rhyen Aircraft Industry Co. Ltd know something I don’t?

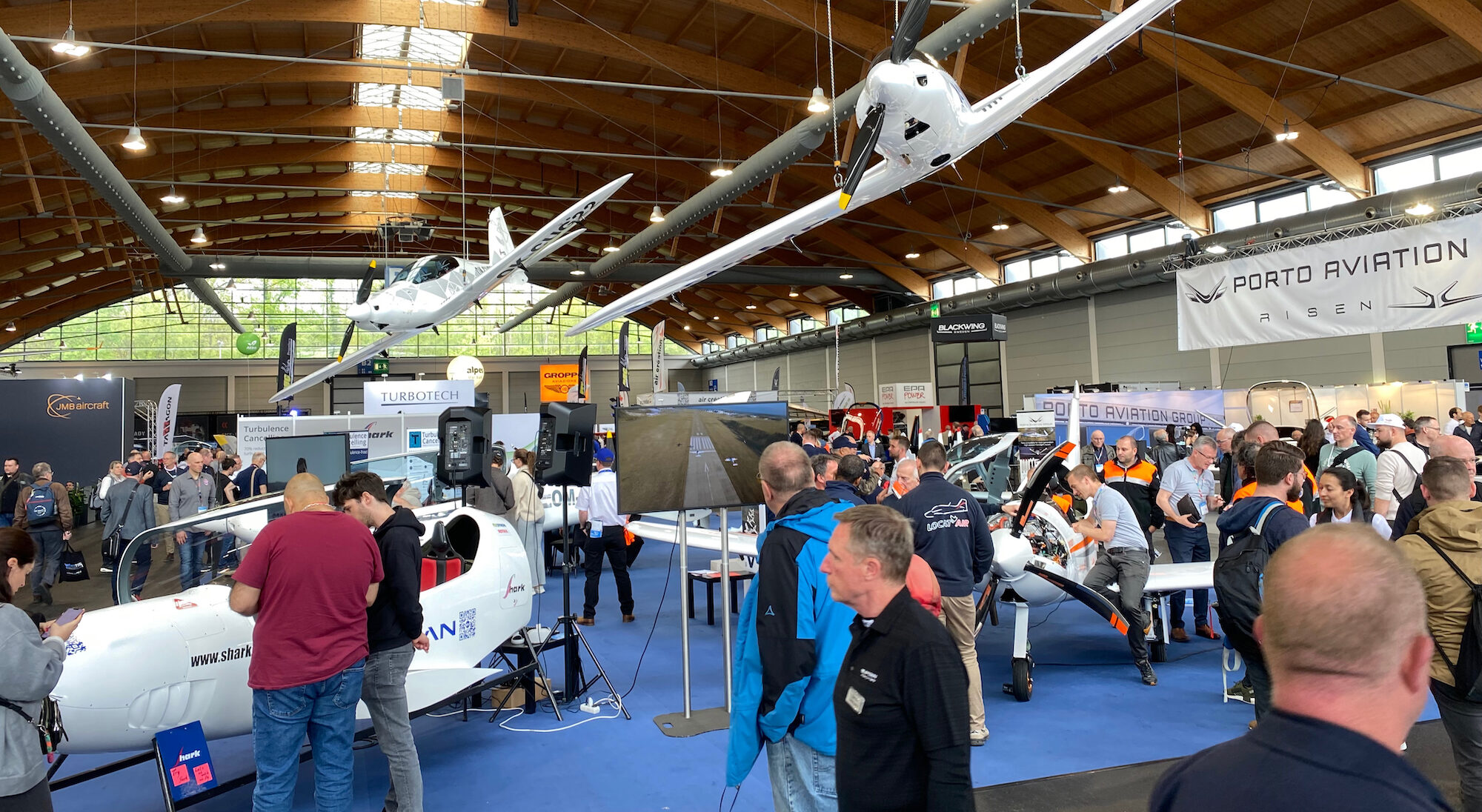

Even the seminars were interesting (if you could drag yourself away from all the wonderful aircraft on show) and LAMA’s President Scott Severin gave an excellent presentation, which included a fine precis of the MOSAIC programme. I enjoyed it very much, although I suspect that EASA’s Jannes Neumann probably didn’t enjoy some of the tricky questions he had to field from some of the European manufacturers!

In the final summing up, the show had 680 exhibitors from 38 nations and 31,500 visitors from 81 countries. Even more impressively, more than 53 percent of AERO visitors indicated that they held a pilot's license. Furthermore, the diverse demographic of attendees emphasized the relevance of the event to the global GA community. With beautifully designed, spacious exhibition halls, good transport links (I can especially recommend the scenic ferry trip across the Bodensee from Romanshorn) and – always of tremendous importance to your correspondent – excellent food and fine German beer, it was another vintage AERO.

The two Chinese RX-1E-A machines from Rhyen Aircraft Industry Co. Ltd were particularly interesting, as they were fitted with batteries that could be quickly and easily removed and exchanged for freshly charged ones. Of course, there’s always a downside: Quickly replaceable batteries are a great idea, until they get dropped. That could be a very expensive mistake! Secondly they can’t be liquid-cooled and having flight-tested two electric aircraft I’m very aware just how important monitoring the temperature of the batteries is. Air-cooling lithium-ion batteries really doesn’t cut it in my experience. Or does the Rhyen Aircraft Industry Co. Ltd know something I don’t?

Even the seminars were interesting (if you could drag yourself away from all the wonderful aircraft on show) and LAMA’s President Scott Severin gave an excellent presentation, which included a fine precis of the MOSAIC programme. I enjoyed it very much, although I suspect that EASA’s Jannes Neumann probably didn’t enjoy some of the tricky questions he had to field from some of the European manufacturers!

In the final summing up, the show had 680 exhibitors from 38 nations and 31,500 visitors from 81 countries. Even more impressively, more than 53 percent of AERO visitors indicated that they held a pilot's license. Furthermore, the diverse demographic of attendees emphasized the relevance of the event to the global GA community. With beautifully designed, spacious exhibition halls, good transport links (I can especially recommend the scenic ferry trip across the Bodensee from Romanshorn) and – always of tremendous importance to your correspondent – excellent food and fine German beer, it was another vintage AERO.

Italian airframer ICP had several aircraft on display including the Ventura 2 ultralight powered by various permutations of Rotax, and also the Experimental, which as well as being fitted with a Rotax can also be powered by a Lycoming of up to 180 hp. The Venture 2 is a side-by-side two-seater, while the Ventura 4 is, as the name suggests, a four-seater specifically designed to meet the requirements of amateur construction and suitable for the Experimental category. ICP claims that a first time builder can reasonably expect to finish the aircraft in between 700 to 800 hours, while a more experienced builder with practical build experience can complete the aircraft in around 400 hours, excluding paint and upholstery. ICP also had the Savannah SR on show, and this machine bore quite a strong resemblance to the Zenith 701. Powered by Rotax 912 and 914 engines, Savannah SR has, according to the company, a cruise speed of 100 knots and an endurance of up to eight hours.

Italian airframer ICP had several aircraft on display including the Ventura 2 ultralight powered by various permutations of Rotax, and also the Experimental, which as well as being fitted with a Rotax can also be powered by a Lycoming of up to 180 hp. The Venture 2 is a side-by-side two-seater, while the Ventura 4 is, as the name suggests, a four-seater specifically designed to meet the requirements of amateur construction and suitable for the Experimental category. ICP claims that a first time builder can reasonably expect to finish the aircraft in between 700 to 800 hours, while a more experienced builder with practical build experience can complete the aircraft in around 400 hours, excluding paint and upholstery. ICP also had the Savannah SR on show, and this machine bore quite a strong resemblance to the Zenith 701. Powered by Rotax 912 and 914 engines, Savannah SR has, according to the company, a cruise speed of 100 knots and an endurance of up to eight hours.

Slovenian company GoGetAir was also offering a show deal on its very attractive G750. With optional 2+2 seating, a high-end car-like interior and a whole airframe parachute recovery system which is capable of saving the airframe up to the 152 knot VNE, the three-blade CS prop is turned by either the 100-hp Rotax 912 iS, the 114-hp 914 or the 141-hp 915 iS. The 915-powered model can cruise at 138 knots IAS, climb at 1450 fpm and reach almost 15,000 feet. Takeoff over a 50-foot obstacle is a very impressive 140m (460 feet). Priced at €249,900 ($267K) the show price included two years or 200 hours of free maintenance if the aircraft was ordered at AERO.

In common with many of the other aircraft at the show avionics options were primarily either Garmin or Dynon, while prop options were either Woodcomp or MT. Unusually in this class, it was also available with two extra seats in the baggage bay, although this configuration did look rather snug. A two-axis digital autopilot comes as standard, while both the exterior and interior could be individually designed at extra cost. They also had a turbine-powered prototype on display, again using the TurboTech engine.

Slovenian company GoGetAir was also offering a show deal on its very attractive G750. With optional 2+2 seating, a high-end car-like interior and a whole airframe parachute recovery system which is capable of saving the airframe up to the 152 knot VNE, the three-blade CS prop is turned by either the 100-hp Rotax 912 iS, the 114-hp 914 or the 141-hp 915 iS. The 915-powered model can cruise at 138 knots IAS, climb at 1450 fpm and reach almost 15,000 feet. Takeoff over a 50-foot obstacle is a very impressive 140m (460 feet). Priced at €249,900 ($267K) the show price included two years or 200 hours of free maintenance if the aircraft was ordered at AERO.

In common with many of the other aircraft at the show avionics options were primarily either Garmin or Dynon, while prop options were either Woodcomp or MT. Unusually in this class, it was also available with two extra seats in the baggage bay, although this configuration did look rather snug. A two-axis digital autopilot comes as standard, while both the exterior and interior could be individually designed at extra cost. They also had a turbine-powered prototype on display, again using the TurboTech engine.

Remaining at the very light end of the sport flying spectrum, German airframer JH aircraft had its electrically powered Corsair e-motion on show. Looking a little like the classic Vought F4U Corsair of World War II and Korean War fame, this machine has a span of 24 feet 6 inches. But just like a real Corsair the wings fold, reducing the span to only 9 feet—not un-trivial if hangarage at your airport is expensive. Powered by an electric motor that can produce a maximum of 30kW/40 hp (20kW/26 hp continuous) it can carry up to 136 pounds of batteries, which the company claims will provide a flight time of up to two-and-a half hours. Compliant with FAR Part 103, it stalls at 24 knots, cruises at 54 knots and climbs at 1200 fpm. Takeoff over a 50ft obstacle is less than 400 feet.

Remaining at the very light end of the sport flying spectrum, German airframer JH aircraft had its electrically powered Corsair e-motion on show. Looking a little like the classic Vought F4U Corsair of World War II and Korean War fame, this machine has a span of 24 feet 6 inches. But just like a real Corsair the wings fold, reducing the span to only 9 feet—not un-trivial if hangarage at your airport is expensive. Powered by an electric motor that can produce a maximum of 30kW/40 hp (20kW/26 hp continuous) it can carry up to 136 pounds of batteries, which the company claims will provide a flight time of up to two-and-a half hours. Compliant with FAR Part 103, it stalls at 24 knots, cruises at 54 knots and climbs at 1200 fpm. Takeoff over a 50ft obstacle is less than 400 feet.

Finnish company Atol Aviation had the cockpit section of its very attractive two-seat side-by-side amphibian on display. Powered by a Rotax 912iS mounted on a pylon in a pusher configuration, this fun looking seaplane features folding wings, a glass cockpit and claimed very low operating costs. It cruises at 86 knots, stalls at 40 and has a range of 450nm. As a seaplane pilot myself I must admit I was very keen to test this particular machine, and hope to visit the manufacturers in Finland later this year.

Finnish company Atol Aviation had the cockpit section of its very attractive two-seat side-by-side amphibian on display. Powered by a Rotax 912iS mounted on a pylon in a pusher configuration, this fun looking seaplane features folding wings, a glass cockpit and claimed very low operating costs. It cruises at 86 knots, stalls at 40 and has a range of 450nm. As a seaplane pilot myself I must admit I was very keen to test this particular machine, and hope to visit the manufacturers in Finland later this year.

Two particularly unusual designs were the Avio SMA Stratos Sport 400 and AS993 Extreme. The Stratos 400 is powered by a 388cc two stroke engine of 50 hp and is configured as a taildragger. It has an empty weight of 110kg (243 pounds) and a maximum takeoff weight of 300kg (661 pounds). With the maximum speed of 54 knots it's no speedster, but the massive wing means a very low wing loading and it stalls at only 18 knots! This very low wing-loading and excellent thrust-to-weight ratio (a claimed 1:2) means that the takeoff run is around 20, (60 feet).

The Extreme is a similar looking design but is powered by a 993cc two-stroke producing 135 hp. It is a slightly heavier empty weight (the max takeoff weight of both the Sport and Extreme is the same at 300kg) and has the same impressive takeoff and landing distances. This intriguing looking Italian design is very competitively priced with the basic Sport kit costing €35,000 $37K) and the basic Extreme kit €40,000 ($43K). Then factor in another €10,000 ($11K) for the 50 hp engine, and €20,000 ($21K) for the 135 hp motor.

Two particularly unusual designs were the Avio SMA Stratos Sport 400 and AS993 Extreme. The Stratos 400 is powered by a 388cc two stroke engine of 50 hp and is configured as a taildragger. It has an empty weight of 110kg (243 pounds) and a maximum takeoff weight of 300kg (661 pounds). With the maximum speed of 54 knots it's no speedster, but the massive wing means a very low wing loading and it stalls at only 18 knots! This very low wing-loading and excellent thrust-to-weight ratio (a claimed 1:2) means that the takeoff run is around 20, (60 feet).

The Extreme is a similar looking design but is powered by a 993cc two-stroke producing 135 hp. It is a slightly heavier empty weight (the max takeoff weight of both the Sport and Extreme is the same at 300kg) and has the same impressive takeoff and landing distances. This intriguing looking Italian design is very competitively priced with the basic Sport kit costing €35,000 $37K) and the basic Extreme kit €40,000 ($43K). Then factor in another €10,000 ($11K) for the 50 hp engine, and €20,000 ($21K) for the 135 hp motor.

Slovakian company Tomark Aero had two machines on display, the SD4 Viper, which is a low wing machine, and the Skyper GT9, which features a strut-braced high-wing. The Viper is available in several different types, including LSA, glider towplane and even a version aimed at training Air Force pilots, while the GT9 is claimed to have good STOL performance . Both are of all-metal construction and mostly powered by the 100 hp Rotax 912 engine, although the towplane SD4 is powered by a ULPower UL305iS. Avionics options include Dynon SkyView and Garmin.

Slovakian company Tomark Aero had two machines on display, the SD4 Viper, which is a low wing machine, and the Skyper GT9, which features a strut-braced high-wing. The Viper is available in several different types, including LSA, glider towplane and even a version aimed at training Air Force pilots, while the GT9 is claimed to have good STOL performance . Both are of all-metal construction and mostly powered by the 100 hp Rotax 912 engine, although the towplane SD4 is powered by a ULPower UL305iS. Avionics options include Dynon SkyView and Garmin.

South African company Jonker has several versions of the “engine-on-stick” solution for its JS3 single seat high performance sailplane, including an electric motor turning a two-blade propeller and a small jet.

South African company Jonker has several versions of the “engine-on-stick” solution for its JS3 single seat high performance sailplane, including an electric motor turning a two-blade propeller and a small jet.

Also of note in the gliding hall was the Lightwing AC4. Looking a little like a stretched C42 Ikarus, the AC4 is built at Stans in Switzerland to Part 21 standards. Powered by a Rotax 915 iS, it was interesting to see how much thought had gone into providing adequate cooling while towing, even though the prop governor has its own dedicated air scoop. Other notable features include a retractable tow rope (there’s an electric winch in the baggage bay) and a rear-view camera, as well as a mirror.

Also of note in the gliding hall was the Lightwing AC4. Looking a little like a stretched C42 Ikarus, the AC4 is built at Stans in Switzerland to Part 21 standards. Powered by a Rotax 915 iS, it was interesting to see how much thought had gone into providing adequate cooling while towing, even though the prop governor has its own dedicated air scoop. Other notable features include a retractable tow rope (there’s an electric winch in the baggage bay) and a rear-view camera, as well as a mirror.

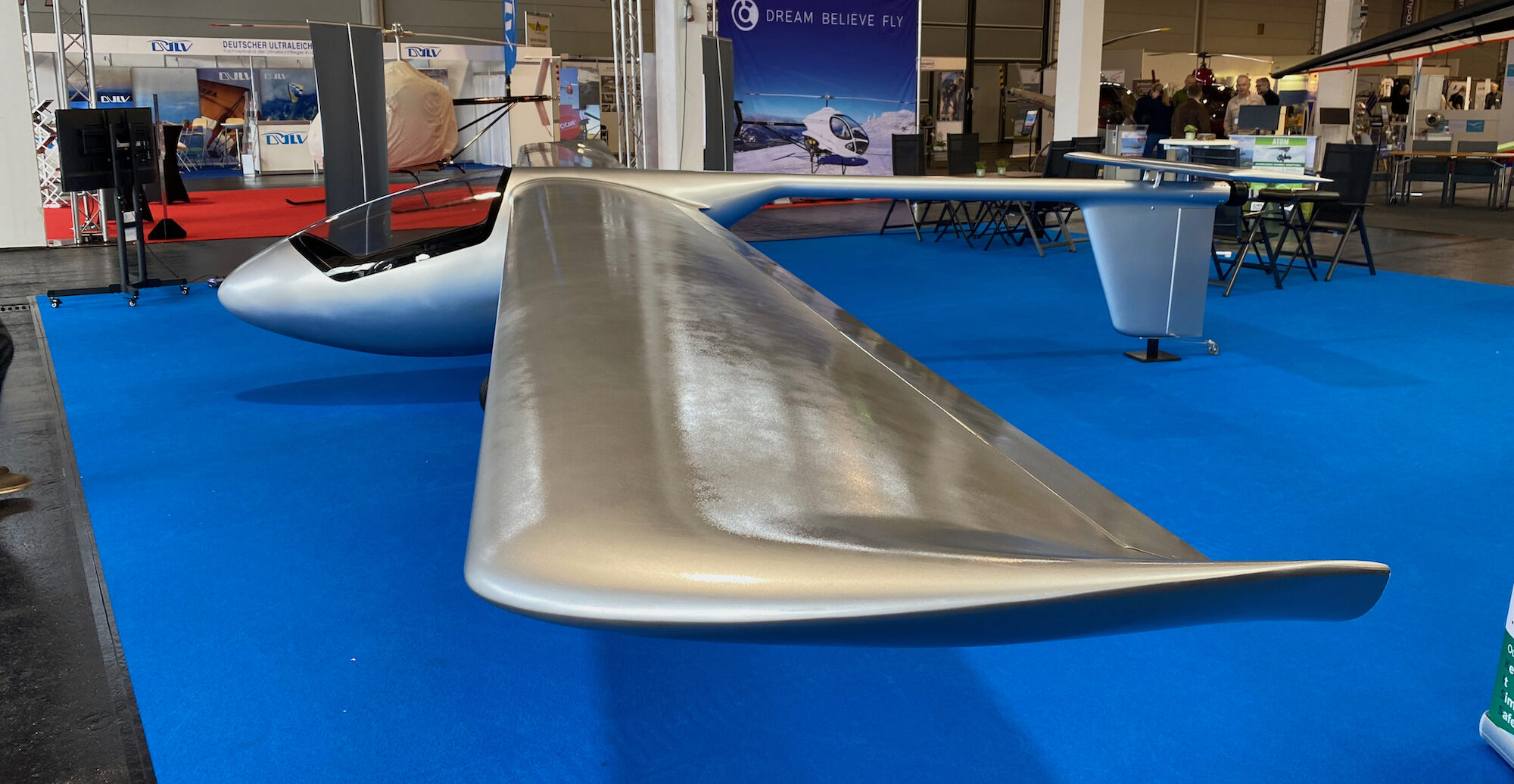

A particularly intriguing machine was the Elektra Solar high-performance electric aircraft. Looking very much like a motorglider, this intriguing aircraft features a retractable monowheel, steerable tailwheel and small outriggers, although it is also available in conventional tailwheel configuration. It is typically stored in a trailer in a similar fashion to a sailplane and the company claims it can be rigged by a single person in approximately 45 minutes, although they did not explain the relevance of the individual’s marital status. The 12kW charging system incorporated into the trailer is claimed to be able to recharge a discharged battery within three hours. The manufacturers also claim that one charge equals one hour of flight time. This is almost certainly because of the very advanced aerodynamics, the machine has a high aspect ratio wing and a best L/D of around 25:1. The company claims it can cruise at 65 knots while only consuming only 12 kW/hr. Another intriguing facet was that the trailer also incorporates solar panels for charging the batteries integrated into the trailer.

A particularly intriguing machine was the Elektra Solar high-performance electric aircraft. Looking very much like a motorglider, this intriguing aircraft features a retractable monowheel, steerable tailwheel and small outriggers, although it is also available in conventional tailwheel configuration. It is typically stored in a trailer in a similar fashion to a sailplane and the company claims it can be rigged by a single person in approximately 45 minutes, although they did not explain the relevance of the individual’s marital status. The 12kW charging system incorporated into the trailer is claimed to be able to recharge a discharged battery within three hours. The manufacturers also claim that one charge equals one hour of flight time. This is almost certainly because of the very advanced aerodynamics, the machine has a high aspect ratio wing and a best L/D of around 25:1. The company claims it can cruise at 65 knots while only consuming only 12 kW/hr. Another intriguing facet was that the trailer also incorporates solar panels for charging the batteries integrated into the trailer.

A particularly unusual electrically powered ultralight glider is the Urfin Juice from Blanik Aircraft, located in Prague in the Czech Republic. This company is the holder of all the Blanik sailplane Type Certificates as well as manufacturing the distinctly distinctive Urfin Juice. This has a best glide ratio of a claimed 27:1 and can cruise at 72 knots. With one battery fitted, it can take off twice to a height of around 600 meters, while if two batteries are fitted it is capable of one hour of powered flight. It certainly did look both intriguing—and fun—while the unusual configuration of a folding pusher prop would undoubtedly pull a crowd wherever you landed.

A particularly unusual electrically powered ultralight glider is the Urfin Juice from Blanik Aircraft, located in Prague in the Czech Republic. This company is the holder of all the Blanik sailplane Type Certificates as well as manufacturing the distinctly distinctive Urfin Juice. This has a best glide ratio of a claimed 27:1 and can cruise at 72 knots. With one battery fitted, it can take off twice to a height of around 600 meters, while if two batteries are fitted it is capable of one hour of powered flight. It certainly did look both intriguing—and fun—while the unusual configuration of a folding pusher prop would undoubtedly pull a crowd wherever you landed.

Staying with unusual motorgliders, the ATOS Wing from German company A-I-R also looks like it would be a lot of fun to fly. With a maximum takeoff weight of only 260kg (573 pounds)it has a claimed best glide ratio of 28:1 and a very low min sink of only 120 fpm. I think it would also be very safe, as it has an extremely slow stall speed of only 22 knots. Very quick to rig (it’s a bit like a modern tent) it’s powered by a small electric motor turning a two-blade folding prop.

Staying with unusual motorgliders, the ATOS Wing from German company A-I-R also looks like it would be a lot of fun to fly. With a maximum takeoff weight of only 260kg (573 pounds)it has a claimed best glide ratio of 28:1 and a very low min sink of only 120 fpm. I think it would also be very safe, as it has an extremely slow stall speed of only 22 knots. Very quick to rig (it’s a bit like a modern tent) it’s powered by a small electric motor turning a two-blade folding prop.

The Altus motorglider is essentially two aircraft in one, as the wing tips are easily interchangeable, changing the wingspan from 36 to 49 feet. The range is over 800 nautical miles, and it is claimed that it can take off in under 500 feet and climb at 1400 fpm. Best glide is a reasonable 24:1 and the Vne is a useful 146 knots. An intriguing option for the Altus purchaser is that it can come supplied with two fold down electric scooters that can be carried behind the cockpit. Powered by a 100-hp Rotax 912 engine, it is available as either taildragger or trigear.

The Altus motorglider is essentially two aircraft in one, as the wing tips are easily interchangeable, changing the wingspan from 36 to 49 feet. The range is over 800 nautical miles, and it is claimed that it can take off in under 500 feet and climb at 1400 fpm. Best glide is a reasonable 24:1 and the Vne is a useful 146 knots. An intriguing option for the Altus purchaser is that it can come supplied with two fold down electric scooters that can be carried behind the cockpit. Powered by a 100-hp Rotax 912 engine, it is available as either taildragger or trigear.

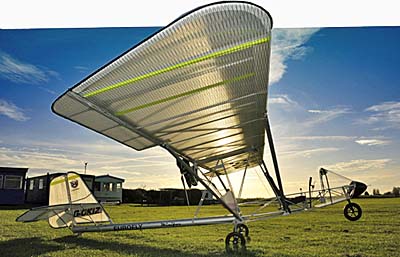

For far too long, the more bigoted aviators among us considered such an aircraft to be little more an overweight hang glider powered by a second-hand lawn mower engine and barely capable of flying fast enough to kill you. Noisy, slow, and smelly — they were considerably less than satisfactory. However, times change and this class of flying machine has changed more than most.

Designed by Frenchman Phillippe Prevot in the early '90s, the original Skyranger was an object lesson in KISS (Keep It Simple, Stupid). Prevot’s intent was that anyone competent with basic tools could build it, as there was no bending, composites, or welding involved. It was to be covered in an equally simple material, Dacron sailcloth.

Easy to build, maintain and fly, more than 1,600 have been produced; nearly 300 are registered in England alone. Beside numerous minor improvements, fundamentally Skyranger has changed little: the ventral fin has been replaced by a taller fin and the wingspan has been reduced.

For far too long, the more bigoted aviators among us considered such an aircraft to be little more an overweight hang glider powered by a second-hand lawn mower engine and barely capable of flying fast enough to kill you. Noisy, slow, and smelly — they were considerably less than satisfactory. However, times change and this class of flying machine has changed more than most.

Designed by Frenchman Phillippe Prevot in the early '90s, the original Skyranger was an object lesson in KISS (Keep It Simple, Stupid). Prevot’s intent was that anyone competent with basic tools could build it, as there was no bending, composites, or welding involved. It was to be covered in an equally simple material, Dacron sailcloth.

Easy to build, maintain and fly, more than 1,600 have been produced; nearly 300 are registered in England alone. Beside numerous minor improvements, fundamentally Skyranger has changed little: the ventral fin has been replaced by a taller fin and the wingspan has been reduced.

Flylight's main subcontractor is Aeros, based in Kiev, Ukraine. Aeros make some of the world's best hang gliders; they are experts in tube and fabric work. They've built Skyrangers for many years. Today, Nynjas are assembled in the UK.

Nynja's airframe is constructed primarily of straight, pin-jointed, aircraft-grade aluminum tubing, covered with a combination of non-structural composite sheets for the fuselage and pre-sewn polyester Xlam fabric for the wings and tailplane. An interesting feature (and one that flags up how speedy the Nynja is) is that the wings feature foam spacers that ensure the aerofoil retains its shape at higher speeds. All the primary controls are actuated by cables, as is the elevator trim. The tailplane is wire-braced and the strut-braced wings feature upswept winglets. An excellent option allows the wings to be folded back for ease of storage.

Flylight's main subcontractor is Aeros, based in Kiev, Ukraine. Aeros make some of the world's best hang gliders; they are experts in tube and fabric work. They've built Skyrangers for many years. Today, Nynjas are assembled in the UK.

Nynja's airframe is constructed primarily of straight, pin-jointed, aircraft-grade aluminum tubing, covered with a combination of non-structural composite sheets for the fuselage and pre-sewn polyester Xlam fabric for the wings and tailplane. An interesting feature (and one that flags up how speedy the Nynja is) is that the wings feature foam spacers that ensure the aerofoil retains its shape at higher speeds. All the primary controls are actuated by cables, as is the elevator trim. The tailplane is wire-braced and the strut-braced wings feature upswept winglets. An excellent option allows the wings to be folded back for ease of storage.

Earlier Skyrangers were powered by several different engines, including the Jabiru 2200, HKS and BMW R100, but these days the

Earlier Skyrangers were powered by several different engines, including the Jabiru 2200, HKS and BMW R100, but these days the  All three wheels feature snug fitting wheel pants. Nynja's main gear is supported by aluminium "half springs" bolted to a steel center tube and feature hydraulic

All three wheels feature snug fitting wheel pants. Nynja's main gear is supported by aluminium "half springs" bolted to a steel center tube and feature hydraulic

Rolling out onto the runway I opened the Rotax up to full power. With 13 gallons of fuel on board Nynja was right on the 992-pound gross weight. It was cool and I checked a slight crosswind from starboard.

With a power-to-weight ratio of less than ten pounds per horsepower, acceleration was excellent and after what seemed a ridiculously short ground roll, the Nynja literally leapt off the runway and clawed itself skyward at an impressively steep angle. With the VSI indicating in excess of 1,200 fpm and a relatively low forward speed of only 62 knots, we crossed the airfield boundary already at more than 1,000 feet. At such an aggressive climb, Nynja's nose was quite pitched up, greatly reducing the field of view, but even lowering it to more a cruise-climb attitude still produced about 700 feet per minute of climb at 80 knots and 5,000 rpm.

With light weight, plenty of power, and crisp controls joining up with Al and Keith in the EuroFox cameraship was easy; collecting the pictures in this article didn’t take long.

Rolling out onto the runway I opened the Rotax up to full power. With 13 gallons of fuel on board Nynja was right on the 992-pound gross weight. It was cool and I checked a slight crosswind from starboard.

With a power-to-weight ratio of less than ten pounds per horsepower, acceleration was excellent and after what seemed a ridiculously short ground roll, the Nynja literally leapt off the runway and clawed itself skyward at an impressively steep angle. With the VSI indicating in excess of 1,200 fpm and a relatively low forward speed of only 62 knots, we crossed the airfield boundary already at more than 1,000 feet. At such an aggressive climb, Nynja's nose was quite pitched up, greatly reducing the field of view, but even lowering it to more a cruise-climb attitude still produced about 700 feet per minute of climb at 80 knots and 5,000 rpm.

With light weight, plenty of power, and crisp controls joining up with Al and Keith in the EuroFox cameraship was easy; collecting the pictures in this article didn’t take long.

For a high wing aircraft, the visibility is quite good, although as is a feature of practically all-high wing aircraft, it is a tiny bit blind in the turn. Another nice touch is the transparent panel in the roof, as if the aircraft is rolled into a very tight turn it is possible to look through the roof. The controls all seemed quite nicely harmonised and authoritative. The roll rate in particular is distinctly sprightly, while both pitch and yaw control were equally effective. Trim is effective.

Moving on to an exploration of the stick-free stability around all three axes, I get the impression the Nynja is strongly positive longitudinally, weakly positive directionally, and neutral laterally.

Slowing down to explore the low speed side of the flight envelope revealed no disagreeable mannerisms. Indeed, with flaps down and carrying a reasonable amount of power the Nynja showed no desire to stall at all, but a more vigorous approach to the stall with the engine off produced a more positive break at about 33 knots, combined with a slight wing drop which was easily controlled by the rudder. I increase power for a look at a departure stall and, as expected, this maneuver provoked a slightly more vigorous response, although the ensuing stall was easily recovered from with minimal height loss. Flaps up, the stall is still less than 40.

For a high wing aircraft, the visibility is quite good, although as is a feature of practically all-high wing aircraft, it is a tiny bit blind in the turn. Another nice touch is the transparent panel in the roof, as if the aircraft is rolled into a very tight turn it is possible to look through the roof. The controls all seemed quite nicely harmonised and authoritative. The roll rate in particular is distinctly sprightly, while both pitch and yaw control were equally effective. Trim is effective.

Moving on to an exploration of the stick-free stability around all three axes, I get the impression the Nynja is strongly positive longitudinally, weakly positive directionally, and neutral laterally.

Slowing down to explore the low speed side of the flight envelope revealed no disagreeable mannerisms. Indeed, with flaps down and carrying a reasonable amount of power the Nynja showed no desire to stall at all, but a more vigorous approach to the stall with the engine off produced a more positive break at about 33 knots, combined with a slight wing drop which was easily controlled by the rudder. I increase power for a look at a departure stall and, as expected, this maneuver provoked a slightly more vigorous response, although the ensuing stall was easily recovered from with minimal height loss. Flaps up, the stall is still less than 40.

The claimed glide angle is a reasonable 9:1 at 55 knots, while minimum sink is modest at around 500 feet per minute at 45 knots.

Cruise is middle-of-the-range at 95 knots, achieved at 5,100 rpm, giving a true air speed of 101 knots at 3,000 feet with a fuel flow of about 4.75 gallons per hour, but the engine does sound somewhat frenetic. A much more comfortable cruise rpm is 4,000, which still gives an IAS of 70 knots (76 true) and a fuel flow of less than 2.6 gallons per hour and a still-air range of over 400 nautical miles, including Day-VFR reserves.

The claimed glide angle is a reasonable 9:1 at 55 knots, while minimum sink is modest at around 500 feet per minute at 45 knots.

Cruise is middle-of-the-range at 95 knots, achieved at 5,100 rpm, giving a true air speed of 101 knots at 3,000 feet with a fuel flow of about 4.75 gallons per hour, but the engine does sound somewhat frenetic. A much more comfortable cruise rpm is 4,000, which still gives an IAS of 70 knots (76 true) and a fuel flow of less than 2.6 gallons per hour and a still-air range of over 400 nautical miles, including Day-VFR reserves.

On approach to landing, I nailed the ASI’s needle to 50 with just a smidgen of throttle and then chopped the power. After Nynja's main wheels touched firmly I lowered the nose and applied maximum braking; I actually locked the wheels up and we skidded momentarily on the damp grass. All total I used a little over 300 feet.

Overall, I thought the Nynja a great little aircraft that offers outstanding value for money. It is a lot of aircraft for the money.

What a cracking little aircraft! Fast, frugal and fun, the latest iteration of the seminal Skyranger might just be the best one yet.

On approach to landing, I nailed the ASI’s needle to 50 with just a smidgen of throttle and then chopped the power. After Nynja's main wheels touched firmly I lowered the nose and applied maximum braking; I actually locked the wheels up and we skidded momentarily on the damp grass. All total I used a little over 300 feet.

Overall, I thought the Nynja a great little aircraft that offers outstanding value for money. It is a lot of aircraft for the money.

What a cracking little aircraft! Fast, frugal and fun, the latest iteration of the seminal Skyranger might just be the best one yet.

A handsome high-wing, side-by-side two seater, Scout’s lineage goes back to 1983, when Dean Wilson’s trendsetter-to-be Avid Flyer was first introduced.

His often-imitated design was the basis for Kitfox, Rocky Mountain’s Ridge Runner and the Flying K Sky Raider. The latter morphed into the Just Aircraft Escapade.

When

A handsome high-wing, side-by-side two seater, Scout’s lineage goes back to 1983, when Dean Wilson’s trendsetter-to-be Avid Flyer was first introduced.

His often-imitated design was the basis for Kitfox, Rocky Mountain’s Ridge Runner and the Flying K Sky Raider. The latter morphed into the Just Aircraft Escapade.

When  Of course, the folding mechanism adds both weight and complexity (two things that light aircraft designers generally try to avoid), but the trade-off in this instance is worth it; the wing-fold mechanism does not add much weight or complexity.

Scout’s constant chord wings are braced by V-struts, with about half of the trailing edge taken up by the large, single-slotted mechanically-actuated flaps with four positions: 0°–10°–25°–40°. Ailerons extend to the cambered tips, which feature large LED position lights.

Of course, the folding mechanism adds both weight and complexity (two things that light aircraft designers generally try to avoid), but the trade-off in this instance is worth it; the wing-fold mechanism does not add much weight or complexity.

Scout’s constant chord wings are braced by V-struts, with about half of the trailing edge taken up by the large, single-slotted mechanically-actuated flaps with four positions: 0°–10°–25°–40°. Ailerons extend to the cambered tips, which feature large LED position lights.

The tail consists of a very slightly swept-back fin and large rudder, a tailplane braced by a combination of struts and wires, and separate elevators. Primary controls are actuated by a mixture of pushrods, bellcranks, and cables. Longitudinal trim is provided by a large tab set into the trailing edge of the left elevator.

The tail consists of a very slightly swept-back fin and large rudder, a tailplane braced by a combination of struts and wires, and separate elevators. Primary controls are actuated by a mixture of pushrods, bellcranks, and cables. Longitudinal trim is provided by a large tab set into the trailing edge of the left elevator. With a maximum width of 44 inches Scout’s cockpit and the extensive glazing gives it a very airy feel. The baggage bay behind the seats has an impressive volume of 17 cubic feet, and its open floor area can take up to 77 pounds. Unusually for an aircraft in this class the seats adjust, secured in position with a positive locking pin.

In another indicator of the high build spec there are toe brakes for both pilots. The tall, slightly curved sticks feel very natural, while levers for the flaps and trim are between the seats. The plunger-type throttle is mounted centrally just below the instrument panel, an easy reach from either seat.

With a maximum width of 44 inches Scout’s cockpit and the extensive glazing gives it a very airy feel. The baggage bay behind the seats has an impressive volume of 17 cubic feet, and its open floor area can take up to 77 pounds. Unusually for an aircraft in this class the seats adjust, secured in position with a positive locking pin.

In another indicator of the high build spec there are toe brakes for both pilots. The tall, slightly curved sticks feel very natural, while levers for the flaps and trim are between the seats. The plunger-type throttle is mounted centrally just below the instrument panel, an easy reach from either seat.

Flight and engine instruments are a mixture of analog and digital — an

Flight and engine instruments are a mixture of analog and digital — an  Ambient conditions are slightly above standard atmospheric, with an airfield elevation of 196 feet and an outside air temperature of 66°F. We had about ten knots on the nose, the grass is short and the acceleration excellent. I doubt we used even the first 300 feet of the 2,700 available. Scout’s climb rate was equally impressive, the best rate of climb of 55 knots produced around 900 fpm.

Ambient conditions are slightly above standard atmospheric, with an airfield elevation of 196 feet and an outside air temperature of 66°F. We had about ten knots on the nose, the grass is short and the acceleration excellent. I doubt we used even the first 300 feet of the 2,700 available. Scout’s climb rate was equally impressive, the best rate of climb of 55 knots produced around 900 fpm. Visibility in the turn — and indeed every phase of flight — was very good for a high-wing aircraft. An exploration of the stick-free stability around all three axes revealed it to be strongly positive longitudinally, weakly positive directionally and positive laterally. Slowing down to examine the stall confirms what I already suspected: this is a very well-mannered flying machine.

As the flaps extend they produce a very slight nose-down pitching moment that is easily trimmed out. There is no stall warning but the speeds are so slow and the deck angle so high that it’s obvious that something isn’t going well. With any flap deployed and irrespective of the power setting it always broke straight ahead, although with the flaps fully up it did have a slight tendency to drop the left wing. With full flaps and a hint of power we got the IAS down to 31 knots.

Visibility in the turn — and indeed every phase of flight — was very good for a high-wing aircraft. An exploration of the stick-free stability around all three axes revealed it to be strongly positive longitudinally, weakly positive directionally and positive laterally. Slowing down to examine the stall confirms what I already suspected: this is a very well-mannered flying machine.

As the flaps extend they produce a very slight nose-down pitching moment that is easily trimmed out. There is no stall warning but the speeds are so slow and the deck angle so high that it’s obvious that something isn’t going well. With any flap deployed and irrespective of the power setting it always broke straight ahead, although with the flaps fully up it did have a slight tendency to drop the left wing. With full flaps and a hint of power we got the IAS down to 31 knots.

At the other side of the speed scale I got the distinct impression that it would probably exceed Vne in straight and level flight, though we didn’t try due to some turblence.

With Keith diligently taking notes, an examination of the cruise revealed that 5,100 rpm at 3,000 feet produced a TAS of 96 knots with a fuel flow of a bit more than four gph. This means that the range at fast cruise is around 360 nm with at least 30 minutes’ fuel left. Pulling the power down to 4,000 rpm saw the fuel flow drop to a bit over two gph. Fit the optional long range tanks and the maximum endurance rises to a butt-bruising eleven hours!

Back at launch airfield I discovered that, as with just about every other aspect of flying the Scout, it’s a very honest aircraft in the pattern, with perhaps the single caveat that pilots converting to it from older, heavier machines need to bear in mind that it has considerably less inertia than a Cessna 152 or Piper Tomahawk. Indeed, for the first few hours it’s probably prudent to stay away from using full flaps because speed bleeds away quickly. Maintain speed at 50 knots over the fence and Scout will touch down where you want it every time. Having got comfortable landing on the long runway 25 I finish off with a smooth three-pointer on the shorter length of turf that parallels the taxiway. Great fun!

One more thing: Folding Scout’s wings is both a quick and simple process while all the controls remain connected. That's great for those who want to use less hangar space or wish to trailer their Scout.

At the other side of the speed scale I got the distinct impression that it would probably exceed Vne in straight and level flight, though we didn’t try due to some turblence.

With Keith diligently taking notes, an examination of the cruise revealed that 5,100 rpm at 3,000 feet produced a TAS of 96 knots with a fuel flow of a bit more than four gph. This means that the range at fast cruise is around 360 nm with at least 30 minutes’ fuel left. Pulling the power down to 4,000 rpm saw the fuel flow drop to a bit over two gph. Fit the optional long range tanks and the maximum endurance rises to a butt-bruising eleven hours!

Back at launch airfield I discovered that, as with just about every other aspect of flying the Scout, it’s a very honest aircraft in the pattern, with perhaps the single caveat that pilots converting to it from older, heavier machines need to bear in mind that it has considerably less inertia than a Cessna 152 or Piper Tomahawk. Indeed, for the first few hours it’s probably prudent to stay away from using full flaps because speed bleeds away quickly. Maintain speed at 50 knots over the fence and Scout will touch down where you want it every time. Having got comfortable landing on the long runway 25 I finish off with a smooth three-pointer on the shorter length of turf that parallels the taxiway. Great fun!

One more thing: Folding Scout’s wings is both a quick and simple process while all the controls remain connected. That's great for those who want to use less hangar space or wish to trailer their Scout.

I honestly feel that TLAC has got a winner here! Obviously care needs to be taken with the weight and balance of the lightest version, but with a typical useful load in excess of 517 pounds the larger Scout is a very practical machine, with good numbers for speed, range and endurance, and the ability to carry a good load into and out of rather short strips. The folding wings are a big plus, while the ability to reconfigure from a nosewheel to a tailwheel quickly and easily could also be very useful. I liked it, a lot.

I honestly feel that TLAC has got a winner here! Obviously care needs to be taken with the weight and balance of the lightest version, but with a typical useful load in excess of 517 pounds the larger Scout is a very practical machine, with good numbers for speed, range and endurance, and the ability to carry a good load into and out of rather short strips. The folding wings are a big plus, while the ability to reconfigure from a nosewheel to a tailwheel quickly and easily could also be very useful. I liked it, a lot.

As I turn onto final James Milnes’ voice suddenly crackles in my headset, “Golf Oscar Kilo Uniform Bravo, don’t forget it’s a tailwheel today!” The reason for James’ timely reminder was that when I’d flown the same aircraft a few weeks previously it had been configured as a trike, but today it’s a taildragger! Like most things in life, sport flying isn’t getting any cheaper. Hangarage, insurance, maintenance and fuel are all getting more expensive. But what if you had an aeroplane that lived on a road-legal trailer and fitted in your garage? One you could fly from practically any friendly farmer’s field while burning only eight liters (about 2 gallons) of mogas an hour and that you could do all the maintenance on?

I give you the Sherwood Kub. Built by

As I turn onto final James Milnes’ voice suddenly crackles in my headset, “Golf Oscar Kilo Uniform Bravo, don’t forget it’s a tailwheel today!” The reason for James’ timely reminder was that when I’d flown the same aircraft a few weeks previously it had been configured as a trike, but today it’s a taildragger! Like most things in life, sport flying isn’t getting any cheaper. Hangarage, insurance, maintenance and fuel are all getting more expensive. But what if you had an aeroplane that lived on a road-legal trailer and fitted in your garage? One you could fly from practically any friendly farmer’s field while burning only eight liters (about 2 gallons) of mogas an hour and that you could do all the maintenance on?

I give you the Sherwood Kub. Built by  Before going flying, a look around the TLAC facility reveals quite a few Kubs in various stages of construction, and the large lift (which wouldn’t look entirely out of place on an aircraft carrier) that conveys completed aircraft from the production line on the first floor down to the ground. Unlike some of the SSDRs that I’ve tested over the years, the Kub looks very well made, and also quite robust. TLAC boss Paul Hendry-Smith explained that although SSDR aircraft don’t need specific approvals from a national aviation authority or administration, as the Kub is descended from the Reality Aircraft Kid, it is built to British Civil Airworthiness Requirements, uses aircraft-quality materials and is “a proper aeroplane.”

Before going flying, a look around the TLAC facility reveals quite a few Kubs in various stages of construction, and the large lift (which wouldn’t look entirely out of place on an aircraft carrier) that conveys completed aircraft from the production line on the first floor down to the ground. Unlike some of the SSDRs that I’ve tested over the years, the Kub looks very well made, and also quite robust. TLAC boss Paul Hendry-Smith explained that although SSDR aircraft don’t need specific approvals from a national aviation authority or administration, as the Kub is descended from the Reality Aircraft Kid, it is built to British Civil Airworthiness Requirements, uses aircraft-quality materials and is “a proper aeroplane.”

Currently offered by TLAC as either a basic kit, "Fast-Build" kit or as a RTF factory-built SSDR microlight, the Kub is of classic rag ‘n’ tube design. Construction is primarily of TIG-welded 4130-gauge aircraft grade steel tube that is then powder-coated. The fuselage has a triangular cross-section aft of the cockpit, while the wings use Avid Flyer/Kitfox-style tubular aluminium spars and plywood ribs. Oratex UL600 covers the fuselage, wings and tail, with composites used for the cowling, which half-covers the Hirth F23 engine.

The Hirth F23 is an air-cooled horizontally-opposed two-stroke twin, which produces 50 horsepower at 6150 rpm and turns the three-blade, fixed-pitch prop via a wide Polyflex V-belt drive with a reduction ratio of 2.2:1. James explains that initially G-OKUB (British "N-numbers" start with a "G") had been fitted with a Hirth F33 single-cylinder two-stroke of only 33 horsepower, but this was soon replaced with the F23, which, he grinned, “has transformed it!”

Currently offered by TLAC as either a basic kit, "Fast-Build" kit or as a RTF factory-built SSDR microlight, the Kub is of classic rag ‘n’ tube design. Construction is primarily of TIG-welded 4130-gauge aircraft grade steel tube that is then powder-coated. The fuselage has a triangular cross-section aft of the cockpit, while the wings use Avid Flyer/Kitfox-style tubular aluminium spars and plywood ribs. Oratex UL600 covers the fuselage, wings and tail, with composites used for the cowling, which half-covers the Hirth F23 engine.

The Hirth F23 is an air-cooled horizontally-opposed two-stroke twin, which produces 50 horsepower at 6150 rpm and turns the three-blade, fixed-pitch prop via a wide Polyflex V-belt drive with a reduction ratio of 2.2:1. James explains that initially G-OKUB (British "N-numbers" start with a "G") had been fitted with a Hirth F33 single-cylinder two-stroke of only 33 horsepower, but this was soon replaced with the F23, which, he grinned, “has transformed it!”

Now, I’m not a huge fan of two-stroke aero-engines. In fact, even my lawnmower’s engine is a four-stroke, so I regard the F23 with a slightly jaundiced air. It’s quite an interesting, almost contradictory little engine, as despite Hirth having replaced the old-school magnetos with dual Capacitive Digital Ignition (CDI) units you still must mix the two-stroke oil into the petrol by hand. I believe automatic oil injection is an option, but even my Yamaha RD400 motorcycle had the oil automatically injected as standard in 1978. The Hirth does have an excellent power to weight ratio though – 50 horsepower from an aero-engine that only weighs 35 kilograms (77 pounds, including the electric starter and twin expansion-chamber exhaust) is not to be sniffed at. It's fed from a pair of wing tanks with a combined capacity of 47 litres (12 gallons) via a fuselage-mounted four-litre (1 gallon) header tank.

The main undercarriage is of the split-vee type fitted with chubby low-pressure tires and heavily slotted Shimano cable-actuated disc brakes. Bungees are used for shock absorption. As both ‘third wheels’ were fitted, it made this particular preflight unique, at least in my experience. The large pneumatic nosewheel is carried by a welded steel-tube frame and free-castors, while the small solid tailwheel is suspended from a single leaf spring and steers via springs through the rudder pedals, up to about thirty degrees each way. A mixture of struts and wires brace the tailplane, which carries separate elevators with a large trim tab set into the trailing edge of the starboard one. The big fin is pleasingly rounded and carries an equally large rudder.

Now, I’m not a huge fan of two-stroke aero-engines. In fact, even my lawnmower’s engine is a four-stroke, so I regard the F23 with a slightly jaundiced air. It’s quite an interesting, almost contradictory little engine, as despite Hirth having replaced the old-school magnetos with dual Capacitive Digital Ignition (CDI) units you still must mix the two-stroke oil into the petrol by hand. I believe automatic oil injection is an option, but even my Yamaha RD400 motorcycle had the oil automatically injected as standard in 1978. The Hirth does have an excellent power to weight ratio though – 50 horsepower from an aero-engine that only weighs 35 kilograms (77 pounds, including the electric starter and twin expansion-chamber exhaust) is not to be sniffed at. It's fed from a pair of wing tanks with a combined capacity of 47 litres (12 gallons) via a fuselage-mounted four-litre (1 gallon) header tank.

The main undercarriage is of the split-vee type fitted with chubby low-pressure tires and heavily slotted Shimano cable-actuated disc brakes. Bungees are used for shock absorption. As both ‘third wheels’ were fitted, it made this particular preflight unique, at least in my experience. The large pneumatic nosewheel is carried by a welded steel-tube frame and free-castors, while the small solid tailwheel is suspended from a single leaf spring and steers via springs through the rudder pedals, up to about thirty degrees each way. A mixture of struts and wires brace the tailplane, which carries separate elevators with a large trim tab set into the trailing edge of the starboard one. The big fin is pleasingly rounded and carries an equally large rudder.

The constant-chord wings are braced by vee-struts and fold aft using a similar system to the Scout’s, but what really catches my eye are the large, single-slotted mechanically-actuated flaps. These have four positions, 0°, 10°, 25°, and 40° but are they really necessary? This thing has a MAUW of only 300 kilograms (661 pounds) and with a wing area of 10.5 square meters (113 square feet) the wing loading is very low, so why would it need flaps? It’s obvious that without some sort of hinged trailing edge it wouldn’t be possible to fold the wings, as they’d foul the fuselage. But does it really need lift-and-drag producing aerodynamic flaps? Only one way to find out: fly it!

The constant-chord wings are braced by vee-struts and fold aft using a similar system to the Scout’s, but what really catches my eye are the large, single-slotted mechanically-actuated flaps. These have four positions, 0°, 10°, 25°, and 40° but are they really necessary? This thing has a MAUW of only 300 kilograms (661 pounds) and with a wing area of 10.5 square meters (113 square feet) the wing loading is very low, so why would it need flaps? It’s obvious that without some sort of hinged trailing edge it wouldn’t be possible to fold the wings, as they’d foul the fuselage. But does it really need lift-and-drag producing aerodynamic flaps? Only one way to find out: fly it!

There are only four circuit breakers and four toggle switches (for the master, avionics master and CDI units), plus a large button for the starter — and that’s pretty well it for the electrical services, as the handheld-type Icom transceiver doesn’t count as installed equipment.

Now it’s time for my mea culpa moment. James had turned on the master and avionics to brief me on the EFIS, and then said, “off you go,” so I set throttle and choke, shouted “clear prop” and pressed the starter. The propeller whirled most convincingly, but the motor didn’t even cough. Further attempts were equally unsatisfactory, then realisation dawned on James and I simultaneously – maybe turning on the dual ignition systems might help? This was the first time I’d ever made this fundamental mistake on a test flight! Lesson learned: if someone else has turned on some of the systems it’s always best to turn off everything and then start from the start, before trying to start! Incidentally, the choke isn’t great (but they’re working on it). It's spring-loaded to the off position and as there’s no parking brake, you run out of hands as you also need to press the starter and guard the throttle. Taxiing out using the hand-operated differential brakes is quite easy, once I’d remembered that — as with all aircraft fitted with a castoring nosewheel — its easier if you keep the speed up a bit.

There are only four circuit breakers and four toggle switches (for the master, avionics master and CDI units), plus a large button for the starter — and that’s pretty well it for the electrical services, as the handheld-type Icom transceiver doesn’t count as installed equipment.

Now it’s time for my mea culpa moment. James had turned on the master and avionics to brief me on the EFIS, and then said, “off you go,” so I set throttle and choke, shouted “clear prop” and pressed the starter. The propeller whirled most convincingly, but the motor didn’t even cough. Further attempts were equally unsatisfactory, then realisation dawned on James and I simultaneously – maybe turning on the dual ignition systems might help? This was the first time I’d ever made this fundamental mistake on a test flight! Lesson learned: if someone else has turned on some of the systems it’s always best to turn off everything and then start from the start, before trying to start! Incidentally, the choke isn’t great (but they’re working on it). It's spring-loaded to the off position and as there’s no parking brake, you run out of hands as you also need to press the starter and guard the throttle. Taxiing out using the hand-operated differential brakes is quite easy, once I’d remembered that — as with all aircraft fitted with a castoring nosewheel — its easier if you keep the speed up a bit.

As you may readily appreciate, the pre-take checks continue the simple theme because the F23 is a two-stroke so it doesn’t need warming up and you can’t even check the oil temperature or pressure. Consequently, my generic SEP "flow check" is quickly completed but — as it always does when flying a two-stroke — the small "Master Caution" light in my brain flickers once or twice. “Have I missed something," I wonder? To be certain, I waited until the CHTs rise slightly then run through the pre-takeoff checks again. Finally convinced I really haven’t forgotten anything, it’s time to fly.

I saw no need to taxi round to runway 25; I simply set the flaps to 10°, opened the throttle and took off from the taxiway. Ambient conditions are above ISA, with an airfield elevation of 196 feet and an OAT of 20°C (68°F). With both tanks full G-OKUB is about 44 kilograms (97 pounds) below the 300 kilogram MAUW. I had a slight crosswind from port but the acceleration is so brisk that the Kub is up and away after about fifty meters (165 feet). The climb rate is equally impressive, the Vy of 45 knots producing over 1,000 fpm. The weather was not good for air-to-air picture taking, so photographer Keith stayed on the ground while I headed off to the west to explore the general handling, control, and stability. Initial impressions were all good. Kub handling is fine around all three axes, with low break-out forces and little "stiction." Unsurprisingly, slow flight is slow. The strut-braced wing uses a relatively high-lift aerofoil and the loading is quite light, barely half that of a Cessna 150.

As you may readily appreciate, the pre-take checks continue the simple theme because the F23 is a two-stroke so it doesn’t need warming up and you can’t even check the oil temperature or pressure. Consequently, my generic SEP "flow check" is quickly completed but — as it always does when flying a two-stroke — the small "Master Caution" light in my brain flickers once or twice. “Have I missed something," I wonder? To be certain, I waited until the CHTs rise slightly then run through the pre-takeoff checks again. Finally convinced I really haven’t forgotten anything, it’s time to fly.

I saw no need to taxi round to runway 25; I simply set the flaps to 10°, opened the throttle and took off from the taxiway. Ambient conditions are above ISA, with an airfield elevation of 196 feet and an OAT of 20°C (68°F). With both tanks full G-OKUB is about 44 kilograms (97 pounds) below the 300 kilogram MAUW. I had a slight crosswind from port but the acceleration is so brisk that the Kub is up and away after about fifty meters (165 feet). The climb rate is equally impressive, the Vy of 45 knots producing over 1,000 fpm. The weather was not good for air-to-air picture taking, so photographer Keith stayed on the ground while I headed off to the west to explore the general handling, control, and stability. Initial impressions were all good. Kub handling is fine around all three axes, with low break-out forces and little "stiction." Unsurprisingly, slow flight is slow. The strut-braced wing uses a relatively high-lift aerofoil and the loading is quite light, barely half that of a Cessna 150.

Stalls — power on or off — are very benign. There is no artificial stall warner, but adequate natural pre-stall buffet. Furthermore, as you approach the stall a reasonable amount of backpressure on the stick is required. Recovery is quick and easy – just release the backpressure. Flaps up Kub stalls at around 28 knots, and although with full flap and some power you can get it down to around 22 knots it's almost academic, as a sensible approach speed is well above stall. Trim is quite precise, although it did seem to run out of aft trim at my weight.

Regarding stick-free stability, the Kub is stable around all three axes, being quite positive longitudinally, softly positive directionally and just barely positive laterally. The roll rate is, as you’d imagine, quite nippy while the visibility in the turn (and most phases of flight) is quite good for a high-wing aircraft.

Stalls — power on or off — are very benign. There is no artificial stall warner, but adequate natural pre-stall buffet. Furthermore, as you approach the stall a reasonable amount of backpressure on the stick is required. Recovery is quick and easy – just release the backpressure. Flaps up Kub stalls at around 28 knots, and although with full flap and some power you can get it down to around 22 knots it's almost academic, as a sensible approach speed is well above stall. Trim is quite precise, although it did seem to run out of aft trim at my weight.

Regarding stick-free stability, the Kub is stable around all three axes, being quite positive longitudinally, softly positive directionally and just barely positive laterally. The roll rate is, as you’d imagine, quite nippy while the visibility in the turn (and most phases of flight) is quite good for a high-wing aircraft.

Cruise performance is also pretty well what you’d expect. A comfortable cruise speed is 50-55 knots, and although you can bump it up to 60 knots, the engine is buzzing quite frenetically and you’ll be burning (relatively) a lot more fuel. For example, at 50 knots you’re only burning around 10 liters an hour (2.6 gph), so the full 51 liters (13.5 gallons) provide a still-air range (including 30 minutes’ reserve fuel) of around 250 nautical miles. If you pull the power right back you can certainly improve the endurance; it’s just that if there’s any appreciable headwind at all then you won’t actually be going anywhere! However, when flying an aircraft like a Kub the journey is at least as important as the destination.

For my first landing I opt for runway 25, which is wider, longer, and directly into wind. This goes well, and as I can see Keith has positioned himself by the mown grass strip (Runway 28) next to the taxiway to shoot some take-off and landing shots I fly several for the camera. This is great fun. The simple pleasure of a well-flown approach never grows old, while the subtle and seamless transference of weight from wing to wheel and back again has never paled, especially if you’ve got an open cockpit (or large window open) and the runway is grass. (This sentence alone is enough to appreciate Dave, don't you think?) As mentioned earlier the test aircraft had a third wheel at both ends and just for laughs (and with a bit of application) I even managed a three-pointer.

Cruise performance is also pretty well what you’d expect. A comfortable cruise speed is 50-55 knots, and although you can bump it up to 60 knots, the engine is buzzing quite frenetically and you’ll be burning (relatively) a lot more fuel. For example, at 50 knots you’re only burning around 10 liters an hour (2.6 gph), so the full 51 liters (13.5 gallons) provide a still-air range (including 30 minutes’ reserve fuel) of around 250 nautical miles. If you pull the power right back you can certainly improve the endurance; it’s just that if there’s any appreciable headwind at all then you won’t actually be going anywhere! However, when flying an aircraft like a Kub the journey is at least as important as the destination.

For my first landing I opt for runway 25, which is wider, longer, and directly into wind. This goes well, and as I can see Keith has positioned himself by the mown grass strip (Runway 28) next to the taxiway to shoot some take-off and landing shots I fly several for the camera. This is great fun. The simple pleasure of a well-flown approach never grows old, while the subtle and seamless transference of weight from wing to wheel and back again has never paled, especially if you’ve got an open cockpit (or large window open) and the runway is grass. (This sentence alone is enough to appreciate Dave, don't you think?) As mentioned earlier the test aircraft had a third wheel at both ends and just for laughs (and with a bit of application) I even managed a three-pointer.

I typically use about 45 knots on final, and although if it’s flat calm you could probably safely shave off another five knots, I’d advise against it. A Kub has plenty of drag and not much inertia; the speed soon washes off. Plus, it sideslips superbly. Furthermore, when landing into just a stiff breeze the speed at touchdown is very slow, possibly less than 10 knots. Brakes are only for taxiing.

I also examine the take-off and landing performance with various flap settings and eventually tried the ultimate test by inverting all normal procedures by taking off with full flap and then landing with no flap. Conclusion: you don’t need any flap at any time, except when folding the wings! My experiments had convinced me that the weight and complexity of the flap system’s lever, cables, pulleys and bell cranks is unnecessary and that — and particularly for the 50 horsepower version — simple pip-pins could be used to hold the flaps in place when rigged for flight.

A few weeks later Keith and I are back, and the weather is great. This time G-OKUB lost the the "training [tail]wheel" and is configured as a taildragger. It looks a lot better, I think. In fact, it looks a little bit like a single seat miniature Aeronca Champ. Slightly chubby and cheeky-looking, it exudes fun. Taxiing out was if anything (and unusually) easier in the taildragger then the trike. S-turning is unnecessary, as visibility over and each side of the nose is good and the tailwheel steers through the rudder pedals whereas the castering nosewheel requires differential braking. While best rate of climb is 45 knots, once I rose above 500 feet I sped up to 55, as this not only improves the view over the nose but also gets me clear of the airfield and chasing the camera Cessna 152 a bit quicker.

I typically use about 45 knots on final, and although if it’s flat calm you could probably safely shave off another five knots, I’d advise against it. A Kub has plenty of drag and not much inertia; the speed soon washes off. Plus, it sideslips superbly. Furthermore, when landing into just a stiff breeze the speed at touchdown is very slow, possibly less than 10 knots. Brakes are only for taxiing.

I also examine the take-off and landing performance with various flap settings and eventually tried the ultimate test by inverting all normal procedures by taking off with full flap and then landing with no flap. Conclusion: you don’t need any flap at any time, except when folding the wings! My experiments had convinced me that the weight and complexity of the flap system’s lever, cables, pulleys and bell cranks is unnecessary and that — and particularly for the 50 horsepower version — simple pip-pins could be used to hold the flaps in place when rigged for flight.

A few weeks later Keith and I are back, and the weather is great. This time G-OKUB lost the the "training [tail]wheel" and is configured as a taildragger. It looks a lot better, I think. In fact, it looks a little bit like a single seat miniature Aeronca Champ. Slightly chubby and cheeky-looking, it exudes fun. Taxiing out was if anything (and unusually) easier in the taildragger then the trike. S-turning is unnecessary, as visibility over and each side of the nose is good and the tailwheel steers through the rudder pedals whereas the castering nosewheel requires differential braking. While best rate of climb is 45 knots, once I rose above 500 feet I sped up to 55, as this not only improves the view over the nose but also gets me clear of the airfield and chasing the camera Cessna 152 a bit quicker.

The air-to-airs with the C-152 carrying Keith and James were not easy as the Kub has practically no overtake, so I have to use a lot of geometric cut-off for the re-joins. With all the pictures recorded I briefly re-flew some of the items off the flight test card to see what — if any, changes in performance and handling had been produced by removing the nosewheel. Unsurprisingly, directional stability is stronger (less keel area in front of the center of pressure) but longitudinal stability weaker (more weight aft of the centre of gravity, exacerbating the limited aft trim). It also seems slightly faster (less drag). It’s also definitely better looking!

During my two test flights I had a lot of fun with the Kub — it’s an absolute hoot! Even the two-stroke engine impressed me; it really does pull well and the rate of climb is spectacular. It really was great fun to bumble about the sky with my elbow out the open window. The handling is crisp, the roll rate nippy and its just… well, fun, for there's something very special about flying rag ‘n’ tube taildraggers from grass; something that is difficult to explain and hard to resist.

So, would a Kub work for you? Ultimately, the only question you need to ask yourself is, “Do I go flying for sixty miles, or for sixty minutes?

(At this time, TLAC's Kub is not offered for sale in the USA.)