Recently I had an exchange with Australian Flying magazine editor, Steve Hitchen. He asked some great questions and after giving my responses I realized some of his question were common ones I hear being discussed. So why not share our give-and-take? Steve’s questions are in blue. I’d like to talk about power. With LSA restricted to 120 KIAS, it seems unlikely we’ll get much engine development to increase power unless regulations change to either allow an increase in speed or gross weight. LSA are getting more power, to wit, Rotax’s new 915iS with 135-horsepower and the Continental Titan line with 180 horsepower. I do not think this is the end of the horsepower boosts …plus LSA speed and/or weight changes could conceivably follow in the USA but are currently not limitations in other countries that accept the ASTM standards as a basis for approval or certification.

By the way, the use of technology seeks not only to save weight. New methods are used because they can, that is, developers don't need to jump through the regulatory hoops as demanded in Part 23. LSA developers can quickly implement new ideas and materials.

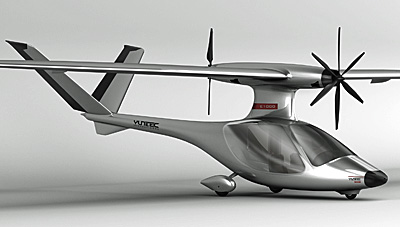

Boeing’s Aurora is one of a flock of new developments aimed at the air taxi trade but it could result in a sport model.

By the way, the use of technology seeks not only to save weight. New methods are used because they can, that is, developers don't need to jump through the regulatory hoops as demanded in Part 23. LSA developers can quickly implement new ideas and materials.

Boeing’s Aurora is one of a flock of new developments aimed at the air taxi trade but it could result in a sport model.

My longtime friend and fellow board member, Tom Peghiny, participated in our annual Light Aircraft Manufacturers Association board of directors meeting at EAA AirVenture Oshkosh, where EAA kindly provides a quiet, air-conditioned space for our group to meet.

My longtime friend and fellow board member, Tom Peghiny, participated in our annual Light Aircraft Manufacturers Association board of directors meeting at EAA AirVenture Oshkosh, where EAA kindly provides a quiet, air-conditioned space for our group to meet.

Since the SP/LSA rule was released in 2004, lithium batteries have grabbed the attention of FAA officials in a very powerful way. The fires onboard Boeing's 787 Dreamliner made news all around the world after FAA had given their approval to the new design.

Today, any talk of advancing electric propulsion on the lightest-of-all aircraft where the technology is currently quite viable brings an immediate response about lithium battery fires. The danger of an onboard fire is so scary that some authorities seem unable to see a solution beyond the hazard.

As board members discussed how to move the needle on LAMA's electric propulsion initiative, board member Tom proposed a scenario that soon had everyone in the board meeting either laughing out loud or smiling broadly. He supposed ... "Imagine if all airplanes were currently powered by electric motors and someone came along with a great new idea to power airplanes with gasoline."

Since the SP/LSA rule was released in 2004, lithium batteries have grabbed the attention of FAA officials in a very powerful way. The fires onboard Boeing's 787 Dreamliner made news all around the world after FAA had given their approval to the new design.

Today, any talk of advancing electric propulsion on the lightest-of-all aircraft where the technology is currently quite viable brings an immediate response about lithium battery fires. The danger of an onboard fire is so scary that some authorities seem unable to see a solution beyond the hazard.

As board members discussed how to move the needle on LAMA's electric propulsion initiative, board member Tom proposed a scenario that soon had everyone in the board meeting either laughing out loud or smiling broadly. He supposed ... "Imagine if all airplanes were currently powered by electric motors and someone came along with a great new idea to power airplanes with gasoline."

Perhaps it would be best if I present Tom's hilarious lines using an imaginary dialogue between an inventor and FAA officials.

INVENTOR: "FAA, I have an idea. I think we might be able to power airplanes with a fluid. It might prove to be very efficient."

FAA: "Oh, what's that? We have to be very careful with new ideas, you know."

INVENTOR: "We'll it's an explosive liquid ... really packs a punch. It could keep aircraft aloft for hours at a time."

FAA: "Explosive! Oh, we don't like the sound of that very much."

INVENTOR: "No, really. This stuff, called gasoline, has a very high energy density, is compact, can be easily loaded onto the aircraft, doesn't cost too much for the energy it delivers ..."

Perhaps it would be best if I present Tom's hilarious lines using an imaginary dialogue between an inventor and FAA officials.

INVENTOR: "FAA, I have an idea. I think we might be able to power airplanes with a fluid. It might prove to be very efficient."

FAA: "Oh, what's that? We have to be very careful with new ideas, you know."

INVENTOR: "We'll it's an explosive liquid ... really packs a punch. It could keep aircraft aloft for hours at a time."

FAA: "Explosive! Oh, we don't like the sound of that very much."

INVENTOR: "No, really. This stuff, called gasoline, has a very high energy density, is compact, can be easily loaded onto the aircraft, doesn't cost too much for the energy it delivers ..."

FAA: "Don't try to snow us with all that technobabble. You said 'explosive,' didn't you? We're still trying to wrap our minds around that."

INVENTOR: "Oh, it can be done without much danger. We'll put the fuel in the wings. We'll put a firewall between the engine and the occupants. Fuel lines will be carefully routed around the cockpit."

FAA: "You mean you want to pump an explosive liquid near the occupants, put it into an engine compartment forward of the cockpit, make a spark many times per second, and explode this stuff in cylinders!?"

INVENTOR: "Yeah, I think it can work really well. This gasoline stuff ... sure it's highly flammable, but we can handle it safely."

FAA: "Flammable! Explosive! Sparks to ignite it! All with the occupants downwind of this stuff!?"

INVENTOR: "Yeah, FAA. This gasoline thing is gonna be big. We might even use it automobiles, in lawn mowers, and in children's toys."

FAA: "Hold on, wait a minute, stop right now. I can't see us approving such an energy source for perhaps years. This sounds crazy. Who would possibly think carrying around hundreds of pounds of explosive liquid in a three dimensional environment could be safe. We're going to have to examine this very carefully. It could take decades."

INVENTOR: "Oh, man. I don't think I can stay in business that long.

FAA: "Yeah, well, we have reliable electric-powered airplanes today. We honestly don't know what you are thinking with this half-baked idea to carry gasoline in airplanes. Plus, we're obliged to alert the automobile, lawn mower, and children's toy regulators since you mentioned those products as well.

FAA: (walking away muttering under their breath...) "What on earth will these crackpots come up with next. Really, gasoline on airplanes. That's just nuts. We better form a new department to confront this possibility. What if Mr. Inventor is right and this gasoline-on-airplanes idea should take off. Crazy ..."

INVENTOR: (sighing deeply...) "Dang it! I thought this was such a great idea, but man, convincing these government folks is going to be tough. Whew! Better join LAMA and see if they can help."

OK, that last sentence is tongue-in-cheek, but that's the story. Hope you liked it. I'm still smiling from Tom's sharp-as-a-pin humor. Thanks, Tom!

• LAMA's four initiatives are: (1) aerial work for LSA; (2) fully-built, SLSA gyroplanes; (3) electric propulsion; and, (4) simplifying the LODA process for training in sub-87 knot airplanes.

FAA: "Don't try to snow us with all that technobabble. You said 'explosive,' didn't you? We're still trying to wrap our minds around that."

INVENTOR: "Oh, it can be done without much danger. We'll put the fuel in the wings. We'll put a firewall between the engine and the occupants. Fuel lines will be carefully routed around the cockpit."

FAA: "You mean you want to pump an explosive liquid near the occupants, put it into an engine compartment forward of the cockpit, make a spark many times per second, and explode this stuff in cylinders!?"

INVENTOR: "Yeah, I think it can work really well. This gasoline stuff ... sure it's highly flammable, but we can handle it safely."

FAA: "Flammable! Explosive! Sparks to ignite it! All with the occupants downwind of this stuff!?"

INVENTOR: "Yeah, FAA. This gasoline thing is gonna be big. We might even use it automobiles, in lawn mowers, and in children's toys."

FAA: "Hold on, wait a minute, stop right now. I can't see us approving such an energy source for perhaps years. This sounds crazy. Who would possibly think carrying around hundreds of pounds of explosive liquid in a three dimensional environment could be safe. We're going to have to examine this very carefully. It could take decades."

INVENTOR: "Oh, man. I don't think I can stay in business that long.

FAA: "Yeah, well, we have reliable electric-powered airplanes today. We honestly don't know what you are thinking with this half-baked idea to carry gasoline in airplanes. Plus, we're obliged to alert the automobile, lawn mower, and children's toy regulators since you mentioned those products as well.

FAA: (walking away muttering under their breath...) "What on earth will these crackpots come up with next. Really, gasoline on airplanes. That's just nuts. We better form a new department to confront this possibility. What if Mr. Inventor is right and this gasoline-on-airplanes idea should take off. Crazy ..."

INVENTOR: (sighing deeply...) "Dang it! I thought this was such a great idea, but man, convincing these government folks is going to be tough. Whew! Better join LAMA and see if they can help."

OK, that last sentence is tongue-in-cheek, but that's the story. Hope you liked it. I'm still smiling from Tom's sharp-as-a-pin humor. Thanks, Tom!

• LAMA's four initiatives are: (1) aerial work for LSA; (2) fully-built, SLSA gyroplanes; (3) electric propulsion; and, (4) simplifying the LODA process for training in sub-87 knot airplanes.

Once upon a time the light aircraft industry announced new manufacturers and models at the rate of two, three, or even more every month ...for several years. As with every maturing industry before, this torrid pace had to slow. Yet the party isn't over, far from it. Contrarily, I am aware of several new projects in the works and we all know of some (Icon, Terrafugia, Lisa among others) where companies have been working on their designs for some years but they have yet to secure FAA approval as a Light-Sport Aircraft. Neither has GreenWing International, a new company announced this week though that may change quickly enough.

Once upon a time the light aircraft industry announced new manufacturers and models at the rate of two, three, or even more every month ...for several years. As with every maturing industry before, this torrid pace had to slow. Yet the party isn't over, far from it. Contrarily, I am aware of several new projects in the works and we all know of some (Icon, Terrafugia, Lisa among others) where companies have been working on their designs for some years but they have yet to secure FAA approval as a Light-Sport Aircraft. Neither has GreenWing International, a new company announced this week though that may change quickly enough.

"Yuneec International, a world leader in electric power systems, is proud to announce the formation of GreenWing International, [which is] entirely focused on bringing the revolution of electric power to the global general aviation market," announced company CEO Tian Yu. Enthusiasts following electric powered aircraft development first saw Yuneec's e430 at AirVenture 2009. The Jiangsu-based company (just north of Shanghai) is very big in electric-powered radio controlled aircraft; their gyro-stabilized RC helicopters have sold in large numbers. Yuneec will continue to focus on developing technologies for electric motors and power systems, but GreenWing said it will handle production of the eSpyder and e430 electric aircraft. Since the first flights of its electric powered planes in 2009, Yuneec has been advancing its electric propulsion technologies, and all GreenWing aircraft will be powered by Yuneec electric propulsion systems.

"Yuneec International, a world leader in electric power systems, is proud to announce the formation of GreenWing International, [which is] entirely focused on bringing the revolution of electric power to the global general aviation market," announced company CEO Tian Yu. Enthusiasts following electric powered aircraft development first saw Yuneec's e430 at AirVenture 2009. The Jiangsu-based company (just north of Shanghai) is very big in electric-powered radio controlled aircraft; their gyro-stabilized RC helicopters have sold in large numbers. Yuneec will continue to focus on developing technologies for electric motors and power systems, but GreenWing said it will handle production of the eSpyder and e430 electric aircraft. Since the first flights of its electric powered planes in 2009, Yuneec has been advancing its electric propulsion technologies, and all GreenWing aircraft will be powered by Yuneec electric propulsion systems.

Since it showed the e430 four years ago, Yuneec acquired the design rights to the former

Since it showed the e430 four years ago, Yuneec acquired the design rights to the former