What if you had a powerful interest in flying but you needed special equipment? I don’t mean flat-screen avionics, powerful engines, or comfortable seats — though all those are indeed fun.

Instead, I refer to people who want to fly but may have challenges many of us don’t face. If you had a passion for flight but you had lost the use of your legs, must you just give up?

Not if Charles Stites and Able Flight have anything to do with it. Of course, personal determination is also required.

Enabling Flight

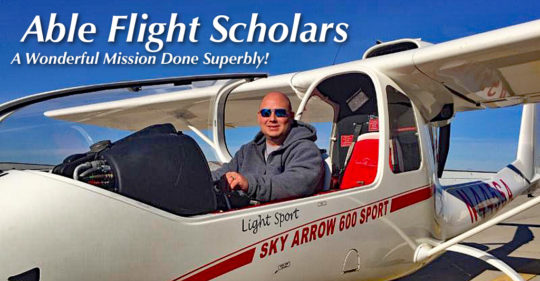

Charles founded Able Flight in 2006 with a believe that, “the life-changing experience of learning to fly is best shared.” He carefully designed the Able Flight Scholarships to enable people with disabilities to pursue that experience and he’s been nothing short of amazing in his success at this. Over 18 years of operation, Able Flight has awarded 130 scholarships minting 98 new pilots.

What if you had a powerful interest in flying but you needed special equipment? I don’t mean flat-screen avionics, powerful engines, or comfortable seats — though all those are indeed fun.

Instead, I refer to people who want to fly but may have challenges many of us don’t face. If you had a passion for flight but you had lost the use of your legs, must you just give up?

Not if Charles Stites and Able Flight have anything to do with it. Of course, personal determination is also required.

Enabling Flight

Charles founded Able Flight in 2006 with a believe that, “the life-changing experience of learning to fly is best shared.” He carefully designed the Able Flight Scholarships to enable people with disabilities to pursue that experience and he’s been nothing short of amazing in his success at this. Over 18 years of operation, Able Flight has awarded 130 scholarships minting 98 new pilots.Able Flight’s Noble Mission — Hand Controls Help More Pilots Enjoy Light-Sport Aircraft

What if you had a powerful interest in flying but you needed special equipment? I don’t mean flat-screen avionics, powerful engines, or comfortable seats — though all those are indeed fun.

Not if Charles Stites and Able Flight have anything to do with it. Of course, personal determination is also required.

Enabling Flight

Charles founded Able Flight in 2006 with a believe that, “the life-changing experience of learning to fly is best shared.” He carefully designed the Able Flight Scholarships to enable people with disabilities to pursue that experience and he’s been nothing short of amazing in his success at this. Over 18 years of operation, Able Flight has awarded 130 scholarships minting 98 new pilots. Able Flight announced that this 2024 class was the largest to-date.

Southern Illinois University in Carbondale assembled members of their team by one of two Vashon Rangers equipped with hand controls. Image from SIU

At an EAA AirVenture Oshkosh ceremony in the Theater in the Woods, Charles introduced the new pilots: Andrew Daigneau, Jake Simmons, Natallia Mirashnichenka, Ian Azeredo, Tyler Pugeda, Omar Duran, Jake Robinson, Jordan Sprague, and Tim Riney Jr.

In addition, this year’s Oshkosh ceremony honored flight instructors who taught the students to fly. Generous support from Able Flight sponsors makes all of this possible; Charles superbly guides the mission but can always use more contributors. This can include you if you are so moved.

Branching Out

Five 2024 students went through a new program at Southern Illinois University (SIU). While this was the first year for operations at SIU, Able Flight has 14-years of experience partnering with Purdue University.

As nearby images Charles took at AirVenture 2024 shows, Vashon has adapted their LSA for hand controls. See reports for other hand control aircraft including Sky Arrow, Montaer, Flight Design, and others. Dennis Long reported that Aeroprakt offered a fresh hand control option at AirVenture 2024. Some years back powered parachute maker Para-Ski even developed a hand-controlled version — PPCs are usually steered by foot pressure on bars.

All interior images by Charles Stites at Vashon Aircraft’s display at AirVenture 2024.

Vashon and its Ranger LSA are newer to the space but warmly welcomed.

To achieve this, Able Flight sought out the expertise of Clayton Smeltz — a pilot and engineer who is a paraplegic. “Smeltz designed adaptive flight controls for his Cirrus SF50 Vision Jet, observed Charles, “and spearheaded the adaptation of the Vashon Ranger with hand controls, enabling it to be flown by individuals with disabilities.”

Interested in a Scholarship?

Applications submitted by December 31, 2024 will be considered for 2025 awards. Interested prospective pilots should apply using this address:

Able Flight

Scholarship Application

91 Oak Leaf Lane

Chapel Hill , NC 27516

- Find full information at the Able Flight website.

What if you had a powerful interest in flying but you needed special equipment? I don’t mean flat-screen avionics, powerful engines, or comfortable seats — though all those are indeed fun.

Instead, I refer to people who want to fly but may have challenges many of us don’t face. If you had a passion for flight but you had lost the use of your legs, must you just give up?

Not if Charles Stites and Able Flight have anything to do with it. Of course, personal determination is also required.

Enabling Flight

Charles founded Able Flight in 2006 with a believe that, “the life-changing experience of learning to fly is best shared.” He carefully designed the Able Flight Scholarships to enable people with disabilities to pursue that experience and he’s been nothing short of amazing in his success at this. Over 18 years of operation, Able Flight has awarded 130 scholarships minting 98 new pilots.

What if you had a powerful interest in flying but you needed special equipment? I don’t mean flat-screen avionics, powerful engines, or comfortable seats — though all those are indeed fun.

Instead, I refer to people who want to fly but may have challenges many of us don’t face. If you had a passion for flight but you had lost the use of your legs, must you just give up?

Not if Charles Stites and Able Flight have anything to do with it. Of course, personal determination is also required.

Enabling Flight

Charles founded Able Flight in 2006 with a believe that, “the life-changing experience of learning to fly is best shared.” He carefully designed the Able Flight Scholarships to enable people with disabilities to pursue that experience and he’s been nothing short of amazing in his success at this. Over 18 years of operation, Able Flight has awarded 130 scholarships minting 98 new pilots.

A phenom in the ultralight world, the

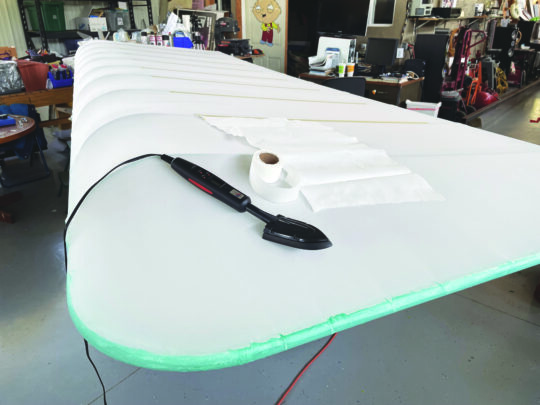

A phenom in the ultralight world, the  To make up for the added weight, Badland’s founder, Chris Deuel, and his team designed and fabricated light but extremely strong wing ribs using carbon fiber and high-density foam composites. The CF ribs are attached to the aluminum spars using epoxy to provide both a strong bond and isolation from the aluminum and to prevent corrosion.

To make up for the added weight, Badland’s founder, Chris Deuel, and his team designed and fabricated light but extremely strong wing ribs using carbon fiber and high-density foam composites. The CF ribs are attached to the aluminum spars using epoxy to provide both a strong bond and isolation from the aluminum and to prevent corrosion.

If you are piloting an ultralight or light plane VFR, you really don’t need an artificial horizon or a heading indicator. But you do need airspeed and altitude, and it’d be nice to have that available in a compact, clear, modern package. Even better, you’d like to make sure everything is happy in the power barn, as well as your airspeed and altitude.

If you are piloting an ultralight or light plane VFR, you really don’t need an artificial horizon or a heading indicator. But you do need airspeed and altitude, and it’d be nice to have that available in a compact, clear, modern package. Even better, you’d like to make sure everything is happy in the power barn, as well as your airspeed and altitude.

With this, the last chapter of the

With this, the last chapter of the

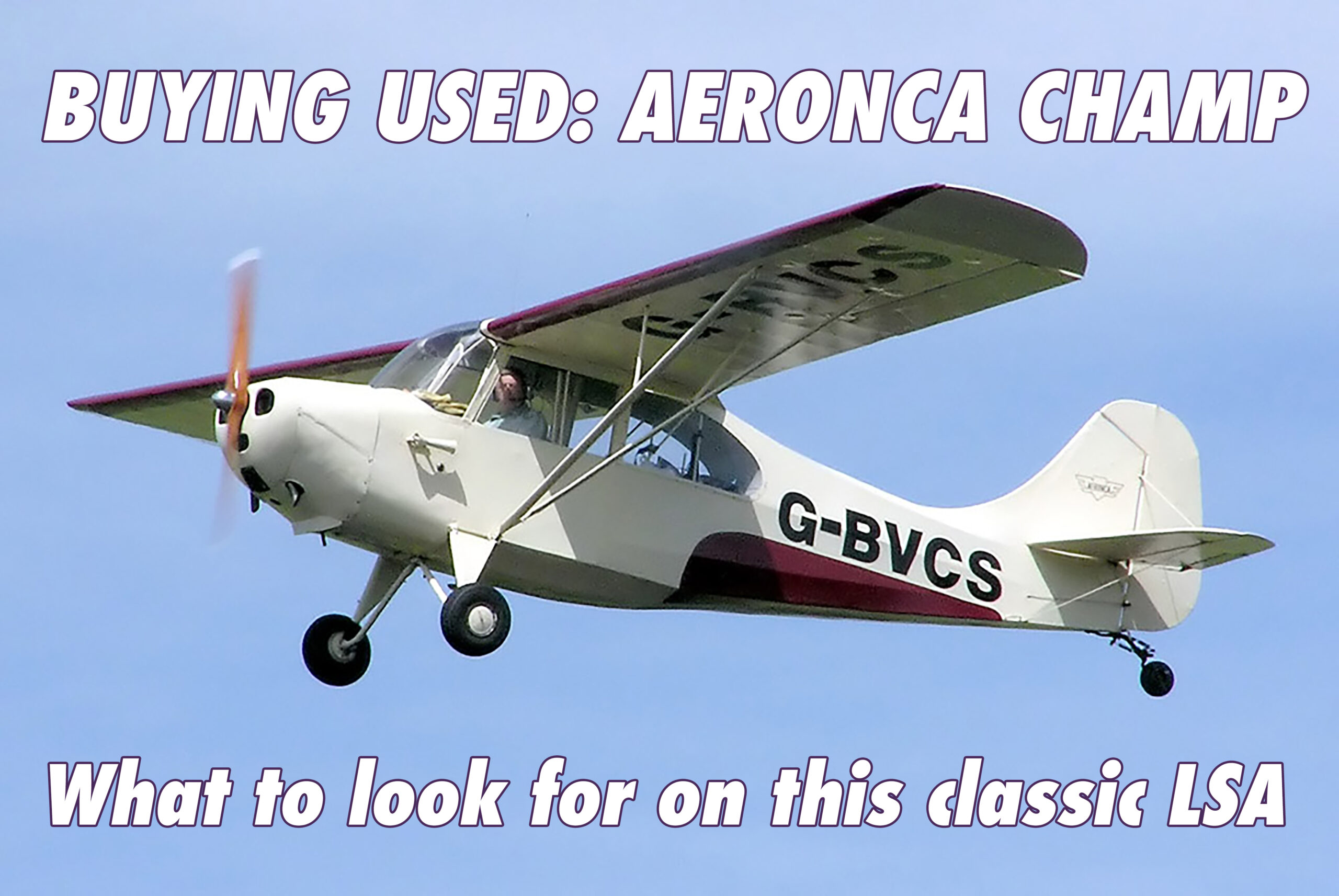

Aeronca Aircraft Corporation began producing Champs in the U.S. in 1945. According to aviation historian Richard Harris, the plane was specifically developed to compete against the Cub and it incorporated some of the aviation lessons of World War II to help it do so. The first model, the 7AC, sold in amazing numbers, with Aeronca reportedly producing an average of 30 Champs a day between 1946 and 1947. However, post-war economic changes brought an end to such massive sales for Aeronca, as well as for all of its competitors. Aeronca put together more than 8000 Champs before it quit making light aircraft in 1951.

Aeronca Aircraft Corporation began producing Champs in the U.S. in 1945. According to aviation historian Richard Harris, the plane was specifically developed to compete against the Cub and it incorporated some of the aviation lessons of World War II to help it do so. The first model, the 7AC, sold in amazing numbers, with Aeronca reportedly producing an average of 30 Champs a day between 1946 and 1947. However, post-war economic changes brought an end to such massive sales for Aeronca, as well as for all of its competitors. Aeronca put together more than 8000 Champs before it quit making light aircraft in 1951. The first Champs had 65-hp Continental engines, but more powerful engines were used from 1947 onward. The BCM and 7DC models had 85hp Continentals, and the electrical system-equipped 7EC had a 90-hp Continental powerplant. Aeronca enlarged the tail and improved the brakes on the more powerful Champs to improve handling in the air and on the ground. Other engines were also tried over the years, including a Lycoming 0-235, a two-cylinder Franklin with 60hp and a 100hp Continental 0-200-A in the last variant made in 2007. The latter model was a revised version of the 7EC, and it included metal-spar wings instead of the traditional wood ones and aluminum gear legs.

The first Champs had 65-hp Continental engines, but more powerful engines were used from 1947 onward. The BCM and 7DC models had 85hp Continentals, and the electrical system-equipped 7EC had a 90-hp Continental powerplant. Aeronca enlarged the tail and improved the brakes on the more powerful Champs to improve handling in the air and on the ground. Other engines were also tried over the years, including a Lycoming 0-235, a two-cylinder Franklin with 60hp and a 100hp Continental 0-200-A in the last variant made in 2007. The latter model was a revised version of the 7EC, and it included metal-spar wings instead of the traditional wood ones and aluminum gear legs.

“Look at that groundspeed!” I exclaimed, pointing at the Garmin EFIS. “Our TAS is nearly 125 knots, which means we’ve got a 60 knot headwind straight on the spinner!” “Can you imagine being up here in a traditional microlight?” asked the Sting’s owner, John Palmer. “No, because not only would I be scared out of my mind at the prospect of having to land, but right now we’d practically be going backwards!” I said.

“Look at that groundspeed!” I exclaimed, pointing at the Garmin EFIS. “Our TAS is nearly 125 knots, which means we’ve got a 60 knot headwind straight on the spinner!” “Can you imagine being up here in a traditional microlight?” asked the Sting’s owner, John Palmer. “No, because not only would I be scared out of my mind at the prospect of having to land, but right now we’d practically be going backwards!” I said.

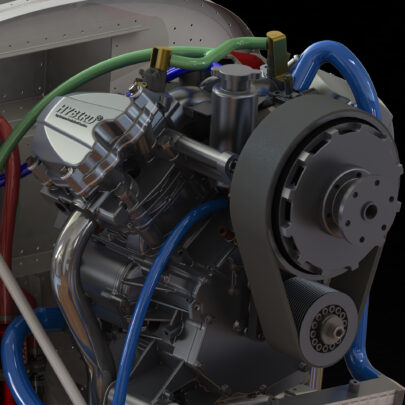

First introduced in Europe in 2013, the all aluminum single seat enclosed cabin Merlin LSA has sported a variety of engines, including a Rotax 582, a specially built four stroke V-twin and even an electric motor. In fact, the Merlin airframe has served as a test bed for all kinds of propulsion and aerodynamic innovations. At AirVenture 2023,

First introduced in Europe in 2013, the all aluminum single seat enclosed cabin Merlin LSA has sported a variety of engines, including a Rotax 582, a specially built four stroke V-twin and even an electric motor. In fact, the Merlin airframe has served as a test bed for all kinds of propulsion and aerodynamic innovations. At AirVenture 2023,

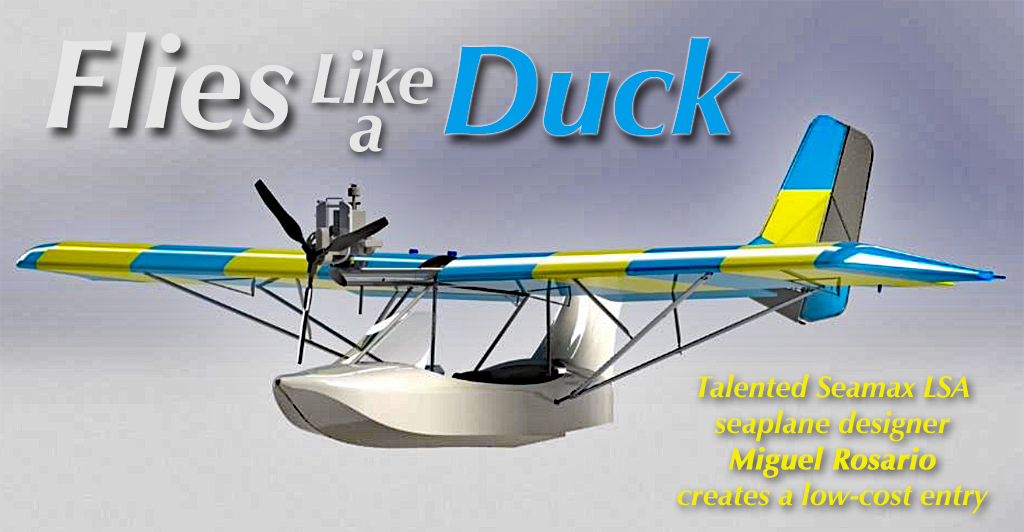

Today, regretfully, the Seamax company is going through some very difficult circumstances as noted in this

Today, regretfully, the Seamax company is going through some very difficult circumstances as noted in this

“I want to share with you the Duck, a design specially made for a Brazilian company called Fly Fox, located in Goiania, Brazil.” Miguel cautioned, “So far, the info I am sharing with you… is for your personal information.” He promised to supply more details; when I hear more I’ll pass it along.

“I want to share with you the Duck, a design specially made for a Brazilian company called Fly Fox, located in Goiania, Brazil.” Miguel cautioned, “So far, the info I am sharing with you… is for your personal information.” He promised to supply more details; when I hear more I’ll pass it along. He continued, “What I made is a ‘reassembled’ Fox V5, using same wings and tail, repositioning

He continued, “What I made is a ‘reassembled’ Fox V5, using same wings and tail, repositioning “[In the last] year, we developed manufacturing templates, where all parts, without exception, are drilled in the same pattern. We made improvements to the aircraft, such as tanks on the wings, laminar landing gear, Celeron pulleys, lighter fairings due to improved resin quality and several other improvements. During this time, parts were manufactured for the kits, today designed in Solid Works, finished with CNC and water cutting. All tubes are made of 6061-T6 aluminum, manufactured under strict quality control.”

“[In the last] year, we developed manufacturing templates, where all parts, without exception, are drilled in the same pattern. We made improvements to the aircraft, such as tanks on the wings, laminar landing gear, Celeron pulleys, lighter fairings due to improved resin quality and several other improvements. During this time, parts were manufactured for the kits, today designed in Solid Works, finished with CNC and water cutting. All tubes are made of 6061-T6 aluminum, manufactured under strict quality control.”

It’s become almost folklore. The quest for affordability in the world of general aviation has been like trying to see the aurora on a cloudy night, or recalling a dog set loose on a squirrel in the forest, or even encountering Bigfoot. From the crash of the post-WW-II airplane buying frenzy, to the mid-1980s liability-fueled dissolution of the general aviation manufacturing industry, to the relative lack of affordability following what the introduction of LSA promised to be, we’re still here, waiting for a real solution.

It’s become almost folklore. The quest for affordability in the world of general aviation has been like trying to see the aurora on a cloudy night, or recalling a dog set loose on a squirrel in the forest, or even encountering Bigfoot. From the crash of the post-WW-II airplane buying frenzy, to the mid-1980s liability-fueled dissolution of the general aviation manufacturing industry, to the relative lack of affordability following what the introduction of LSA promised to be, we’re still here, waiting for a real solution.

These paths to affordability actually do converge. Countless intersections join the expansive future potential bound-up in MOSAIC, and the real, tangible, existing world of general aviation. Some important intersections are the result of:

These paths to affordability actually do converge. Countless intersections join the expansive future potential bound-up in MOSAIC, and the real, tangible, existing world of general aviation. Some important intersections are the result of:

Sure, Sun ‘n Fun, Aero Friedrichshafen, and AirVenture Oshkosh are far larger… and that’s the problem. Size does matter but not always the way you think.

Sure, Sun ‘n Fun, Aero Friedrichshafen, and AirVenture Oshkosh are far larger… and that’s the problem. Size does matter but not always the way you think. At these wonderfully huge events, you have so much to see and so many people to talk to that you cannot get to everyone. When you do end up in the front of a waiting line to talk to a vendor, you may have be quick as many others are waiting and the vendor wants to serve all the customers he or she can. The sheer size of these events also means literally miles of walking on some days. I don’t even want to mention the lines of plastic portapottys baking in the sun. Whew!

At these wonderfully huge events, you have so much to see and so many people to talk to that you cannot get to everyone. When you do end up in the front of a waiting line to talk to a vendor, you may have be quick as many others are waiting and the vendor wants to serve all the customers he or she can. The sheer size of these events also means literally miles of walking on some days. I don’t even want to mention the lines of plastic portapottys baking in the sun. Whew! Comfortably after Oshkosh, on September 5-6-7, 2024, Midwest Aviation Expo is a calm and thoroughly enjoyable gathering. They’ve selected this date carefully and weather has usually been excellent. The area around the airport is wide open, very accommodating of demo flights.

Comfortably after Oshkosh, on September 5-6-7, 2024, Midwest Aviation Expo is a calm and thoroughly enjoyable gathering. They’ve selected this date carefully and weather has usually been excellent. The area around the airport is wide open, very accommodating of demo flights. “Several Sponsorships and Partnerships are in place and some 9-10 new Exhibitors are registered,” said lead organizer Jana Filip. Vendors commonly return year after year; see articles below. “Chris Collins will be going to Oshkosh to promote the event.”

“Several Sponsorships and Partnerships are in place and some 9-10 new Exhibitors are registered,” said lead organizer Jana Filip. Vendors commonly return year after year; see articles below. “Chris Collins will be going to Oshkosh to promote the event.”

Rebadged for 2024,

Rebadged for 2024,

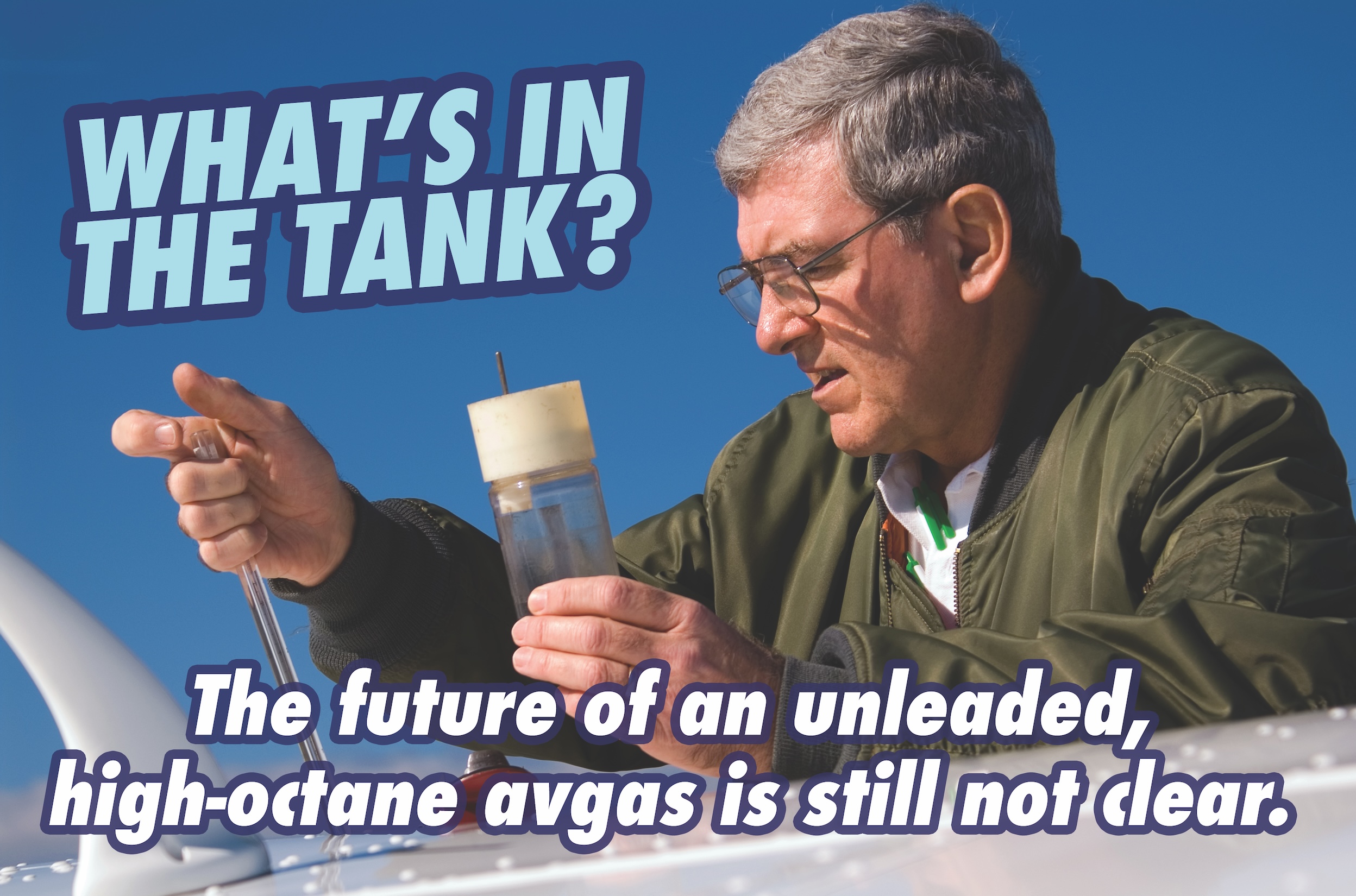

The ongoing issue of finding a replacement for leaded avgas took an ugly turn recently after

The ongoing issue of finding a replacement for leaded avgas took an ugly turn recently after

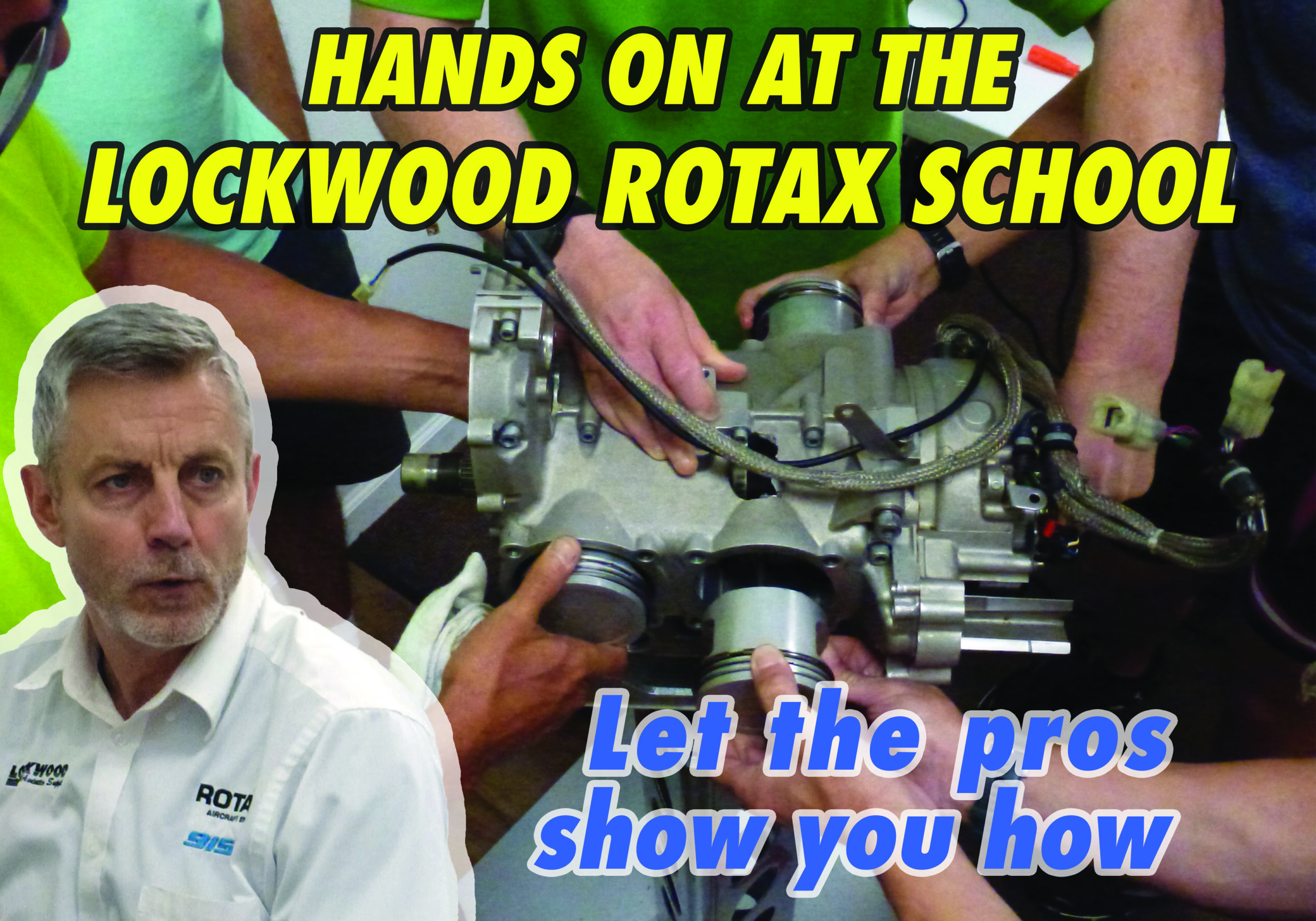

As the class went on we quickly got into the guts of the engine. No, you don’t need to bring safety glasses or rubber gloves to keep your hands clean, and Dean was generous with passing around parts to examine and using them to illustrate the system he was talking about, telling the story behind a broken connecting rod or dented piston and how to avoid it happening. Training is also done on a “penguin,” a flightless aircraft that had been damaged in a mishap. The engine mounted to it was also non-flyable, making it a perfect training tool for mechanics to practice on an engine that can run, but will not put lives at risk if someone makes a mistake.

As the class went on we quickly got into the guts of the engine. No, you don’t need to bring safety glasses or rubber gloves to keep your hands clean, and Dean was generous with passing around parts to examine and using them to illustrate the system he was talking about, telling the story behind a broken connecting rod or dented piston and how to avoid it happening. Training is also done on a “penguin,” a flightless aircraft that had been damaged in a mishap. The engine mounted to it was also non-flyable, making it a perfect training tool for mechanics to practice on an engine that can run, but will not put lives at risk if someone makes a mistake.