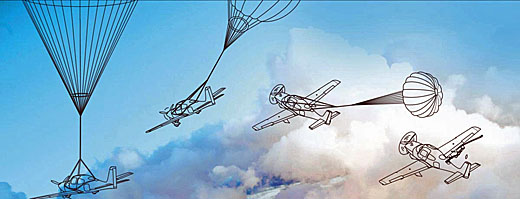

“You just saved my life!” It’s not often anyone, even a medical doctor, hears those words. Back in the ’90s I was sometimes on the receiving end of a call when a pilot phoned BRS to report a “save,” a sparing of a life by the use of a parachute. It is a humbling experience to have someone exclaim that you (and your fellow workers) are the reason they are alive. A few days ago, it happened again, for the 400th time. BRS Aerospace documented the 400th and 401st lives saved, a worthy milestone in aviation safety. “This milestone and all of the lives saved are a testament to Boris Popov, who conceived the idea and whose vision for the company he founded overcame initial resistance to the very idea of aircraft parachutes from some naysayers,” said BRS President and Director, Enrique Dillon. “The concept’s legacy are the pilots and passengers who survived to continue to live fruitful lives and the thousands of families who have enjoyed added peace of mind when their loved ones fly.” The system is designed to be a last resort for pilots and passengers when all other attempts to recover the airplane in case of emergency or pilot incapacitation have failed.

"You just saved my life!" It's not often anyone, even a medical doctor, hears those words. Back in the '90s I was sometimes on the receiving end of a call when a pilot phoned BRS to report a "save," a sparing of a life by the use of a parachute. It is a humbling experience to have someone exclaim that you (and your fellow workers) are the reason they are alive.

A few days ago, it happened again, for the 400th time.

"You just saved my life!" It's not often anyone, even a medical doctor, hears those words. Back in the '90s I was sometimes on the receiving end of a call when a pilot phoned BRS to report a "save," a sparing of a life by the use of a parachute. It is a humbling experience to have someone exclaim that you (and your fellow workers) are the reason they are alive.

A few days ago, it happened again, for the 400th time.  The system is designed to be a last resort for pilots and passengers when all other attempts to recover the airplane in case of emergency or pilot incapacitation have failed.

Numbers 400 and 401 entered the BRS save logbook when the pilot of a Cirrus aircraft with an engine out deployed the whole aircraft rescue system over water more than 20 miles from Grand Turk Island in the Turks and Caicos. BRS reported that pilot and passenger were uninjured and that they were picked up by a cruise ship.

The system is designed to be a last resort for pilots and passengers when all other attempts to recover the airplane in case of emergency or pilot incapacitation have failed.

Numbers 400 and 401 entered the BRS save logbook when the pilot of a Cirrus aircraft with an engine out deployed the whole aircraft rescue system over water more than 20 miles from Grand Turk Island in the Turks and Caicos. BRS reported that pilot and passenger were uninjured and that they were picked up by a cruise ship.

Numerous European and U.S. ultralight and experimental aircraft use the system, including Lancair, Carbon Cub, Kitfox, Glassair,

Numerous European and U.S. ultralight and experimental aircraft use the system, including Lancair, Carbon Cub, Kitfox, Glassair,

By the way, the use of technology seeks not only to save weight. New methods are used because they can, that is, developers don't need to jump through the regulatory hoops as demanded in Part 23. LSA developers can quickly implement new ideas and materials.

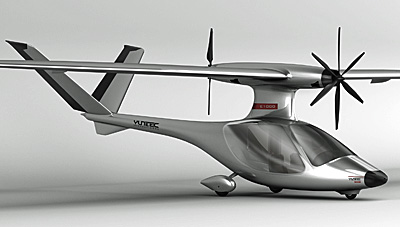

Boeing’s Aurora is one of a flock of new developments aimed at the air taxi trade but it could result in a sport model.

By the way, the use of technology seeks not only to save weight. New methods are used because they can, that is, developers don't need to jump through the regulatory hoops as demanded in Part 23. LSA developers can quickly implement new ideas and materials.

Boeing’s Aurora is one of a flock of new developments aimed at the air taxi trade but it could result in a sport model.

Is your aviation horizon is getting confused by

Is your aviation horizon is getting confused by

Not to be left out by their European rival, this week

Not to be left out by their European rival, this week