Named “Ultra Air,” the newest Hawk Single sounds like it might be Apple’s new laptop computer. In our analog world, Hawk Ultra Air is nearly the exact opposite… except it is a light aircraft. Many might say it’s “ultra” fun so, hey!, the model name works. “Less is more” is also a phrase that might apply to both Hawk and Apple. Hawk Ultra Air looks lighter and slimmer by removing the fabric enclosure. Appearing lean and minimal has appeal to many consumers. Forty one years after its splashy introduction, Hawks now number more than 2,500 aircraft, a fine accomplishment for any manufacturer but especially for one so modestly priced and significantly hand built. Saying Hawk is “hand built” speaks to some of the work Bob Santom, and his son LB have done as they took over one segment of the Hawk lineage. They have laboriously reassembled some earlier aircraft making extensive notes and preparing for continued manufacture, but became better informed than when they started.

Despite showing July 2018 dates about prices on the CGS Hawk website, those numbers remain current! Let me restate. The price of a Hawk Ultra — now the Ultra Air version — has not gone up in price over the last five years! Tell me anything in your life that compares. Nearly everything you buy has gone up 50-100% or more in the last three years alone.

So, I can say with confidence that you can likely still buy a Hawk Ultra airframe kit for $12,500 (no increase since 2018) and you can assemble it in 250 hours. Add a Polini 303 engine for $6,000 plus basic instrumentation or other minor accessories and you'll invest about $22-23,000 to get airborne in a brand-new CGS Hawk. Mount a used engine and you could airborne for less than $20,000. In 2023 America, that is an excellent price.

Despite showing July 2018 dates about prices on the CGS Hawk website, those numbers remain current! Let me restate. The price of a Hawk Ultra — now the Ultra Air version — has not gone up in price over the last five years! Tell me anything in your life that compares. Nearly everything you buy has gone up 50-100% or more in the last three years alone.

So, I can say with confidence that you can likely still buy a Hawk Ultra airframe kit for $12,500 (no increase since 2018) and you can assemble it in 250 hours. Add a Polini 303 engine for $6,000 plus basic instrumentation or other minor accessories and you'll invest about $22-23,000 to get airborne in a brand-new CGS Hawk. Mount a used engine and you could airborne for less than $20,000. In 2023 America, that is an excellent price.

We didn't see the two-place Hawk organization at airshows this year, but I did run into a young engineer who is working with Joseph. Our paths crossed while attending AirVenture 2023. He was excited to tell me how their team is going deeply into a full CAD rework of the Hawk SLSA and other two-place models.

I know from personal experience at following the Hawk for many years that engineering documentation was not developer Chuck Slusarczyk's strong suit. His design has clearly proven itself through decades, but the original engineering work was closer to back-of-the-envelope sketches. Like other gifted designers, Chuck simply knew it all in his head.

We didn't see the two-place Hawk organization at airshows this year, but I did run into a young engineer who is working with Joseph. Our paths crossed while attending AirVenture 2023. He was excited to tell me how their team is going deeply into a full CAD rework of the Hawk SLSA and other two-place models.

I know from personal experience at following the Hawk for many years that engineering documentation was not developer Chuck Slusarczyk's strong suit. His design has clearly proven itself through decades, but the original engineering work was closer to back-of-the-envelope sketches. Like other gifted designers, Chuck simply knew it all in his head.

At it for seven years now, building single place Hawks, Bob emphasized, "I wouldn't trade those seven years for anything. It has been a learning experience but we have met so many great people, pilots who love their Hawk." Now with Hawk Ultra Air capturing attention and given its modest cost, I feel sure CGS has a bright future.

At it for seven years now, building single place Hawks, Bob emphasized, "I wouldn't trade those seven years for anything. It has been a learning experience but we have met so many great people, pilots who love their Hawk." Now with Hawk Ultra Air capturing attention and given its modest cost, I feel sure CGS has a bright future.

Hear about

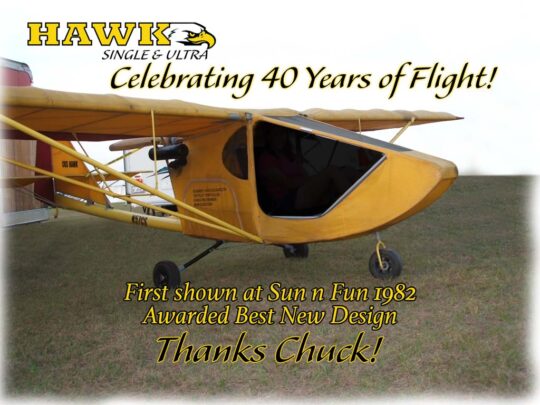

Hear about  I can remember firsthand when one of aviation's true characters — Chuck Slusaczyk, of Chuck's Glider Supplies or CGS — brought his first Hawk to Sun 'n Fun. As this article illustrates, that was 40 years ago!

Yes, fellow fun flyers, 2022 is the year aviation celebrates the 40th anniversary of Part 103 and the emergence of the "ultralight vehicle."

One of the ground-breaking designs that year (1982) was the CGS Hawk. When Chuck introduced this flying machine, he broke some of the rules and went on to sell more than 2,500 of the popular series. What rules did he break?

I can remember firsthand when one of aviation's true characters — Chuck Slusaczyk, of Chuck's Glider Supplies or CGS — brought his first Hawk to Sun 'n Fun. As this article illustrates, that was 40 years ago!

Yes, fellow fun flyers, 2022 is the year aviation celebrates the 40th anniversary of Part 103 and the emergence of the "ultralight vehicle."

One of the ground-breaking designs that year (1982) was the CGS Hawk. When Chuck introduced this flying machine, he broke some of the rules and went on to sell more than 2,500 of the popular series. What rules did he break?

A longtime friend of the Slusarczyk family, Tim was bound and determined to save Hawk #1 from disintegrating in the Florida sun. "As I understand it," Bob said, "Tim negotiated with the Museum staff to acquire Hawk #1, so long as it was never flown again, and Tim's intention was to move the plane to his personal hangar in Florida, with plans for a future renovation."

Bob continued, "After the acquisition, Tim and Laura moved to Tennessee and took Hawk #1 with them, storing it in Tim's rented hangar, again with the intention of renovating her someday.

A longtime friend of the Slusarczyk family, Tim was bound and determined to save Hawk #1 from disintegrating in the Florida sun. "As I understand it," Bob said, "Tim negotiated with the Museum staff to acquire Hawk #1, so long as it was never flown again, and Tim's intention was to move the plane to his personal hangar in Florida, with plans for a future renovation."

Bob continued, "After the acquisition, Tim and Laura moved to Tennessee and took Hawk #1 with them, storing it in Tim's rented hangar, again with the intention of renovating her someday.

"Unfortunately, and tragically, Tim was killed in a light aircraft crash on September 10, 2020, in Sweetwater, Tennessee. Laura was not able to keep the hangar and moved Hawk #1 to a barn at her home.

"Since Tim and Laura were longtime Hawk fans," Bob remembered, "our paths crossed after we acquired the single seat and ultralight manufacturing rights. Conversations ensued about how most everyone believed that Hawk #1 was a very important and historical airplane, worthy of preservation. As [one of] the first true three-axis ultralight-type flying machines that literally and positively changed our industry for many years to come, restoring #1 is a tribute to Chuck as well as all of the Hawk faithful."

"Via mutual Hawk enthusiasts and after spending time with Laura, we bought Hawk #1 and transported her back to our shop in Port St. Lucie, Florida," explained Bob.

"Unfortunately, and tragically, Tim was killed in a light aircraft crash on September 10, 2020, in Sweetwater, Tennessee. Laura was not able to keep the hangar and moved Hawk #1 to a barn at her home.

"Since Tim and Laura were longtime Hawk fans," Bob remembered, "our paths crossed after we acquired the single seat and ultralight manufacturing rights. Conversations ensued about how most everyone believed that Hawk #1 was a very important and historical airplane, worthy of preservation. As [one of] the first true three-axis ultralight-type flying machines that literally and positively changed our industry for many years to come, restoring #1 is a tribute to Chuck as well as all of the Hawk faithful."

"Via mutual Hawk enthusiasts and after spending time with Laura, we bought Hawk #1 and transported her back to our shop in Port St. Lucie, Florida," explained Bob.

In 2017, Bob Santom and his wife Marlene came to agreement and the Santom family took over rights and production of all CGS Hawk single-seat aircraft. This includes the Classic, Arrow I, Sport, Plus, and Ultra. As he operates "CGS Hawk Single and Ultra," Bob is assisted by his two sons, LB and Jonah, though the latter is part time as he has a full-time gig with Cirrus Design.

In 2017, Bob Santom and his wife Marlene came to agreement and the Santom family took over rights and production of all CGS Hawk single-seat aircraft. This includes the Classic, Arrow I, Sport, Plus, and Ultra. As he operates "CGS Hawk Single and Ultra," Bob is assisted by his two sons, LB and Jonah, though the latter is part time as he has a full-time gig with Cirrus Design.  In 2019, Terry also reached agreement with

In 2019, Terry also reached agreement with  When Danny Dezauche took over the design, he did what he could, but I examined what he received and he faced a major challenge. The documentation needed quite a bit of work. Danny kept the brand alive but he was realistic about the daunting amount of work ahead. It was probably appropriate when

When Danny Dezauche took over the design, he did what he could, but I examined what he received and he faced a major challenge. The documentation needed quite a bit of work. Danny kept the brand alive but he was realistic about the daunting amount of work ahead. It was probably appropriate when  With Hawk, you just buy sewn Dacron "sails," a term carried over from the days when such wing coverings were adapted from sailboat sails. You slip them on, tighten them up, and you are largely done. Years later, when replacement may be needed, you can simply buy a new set of sails, which is much lower cost and far less labor than recovering (though dope and fabric coverings may go many years with no need of replacement). Dacron sails are $3,100 so the covered kit price is $15,600 before engine.

With Hawk, you just buy sewn Dacron "sails," a term carried over from the days when such wing coverings were adapted from sailboat sails. You slip them on, tighten them up, and you are largely done. Years later, when replacement may be needed, you can simply buy a new set of sails, which is much lower cost and far less labor than recovering (though dope and fabric coverings may go many years with no need of replacement). Dacron sails are $3,100 so the covered kit price is $15,600 before engine.

Whatever your choice, the engine may run $3,000 to $6,000. Add a few instruments and a couple other refinements and your Hawk Ultra could total $22,000 to $25,000 in flying form.

Bob Santom said the

Whatever your choice, the engine may run $3,000 to $6,000. Add a few instruments and a couple other refinements and your Hawk Ultra could total $22,000 to $25,000 in flying form.

Bob Santom said the  This video was recorded shortly after the Santoms took over the single place Hawk line — and before

This video was recorded shortly after the Santoms took over the single place Hawk line — and before

The Santoms will take over production and sales of the single place Hawk models including the Part 103 model and the Ultra, a somewhat beefier model that is built as an Experimental Amateur Built (EAB). My discussion with Bob and LB was encouraging. I was impressed to hear the enthusiasm from father and son for keeping this series of Hawks available.

This is great news for Hawk fans. The two place models Terry Short and son have been assembling look great and will continue. This includes the FAA-accepted LSA model powered by the Rotax 912. Terry is busy enough that the single place models were lower on his to-do list so in stepped the Santoms who will assure the single place models get extra attention.

"We're located on an airport community about 60 miles from Terry's Lake Wales Airport location," said Bob.

This will make it easy on both enterprises as the Santoms will lean on Terry's fabrication abilities as they use many parts that are interchangeable between the single and two-seat models of Hawk.

"We talked to many Hawk enthusiasts at recent shows and we were pleased to hear of genuine interest in the single place models," Bob added.

As you can see by the bare bones Hawk they exhibited, the new operation is just getting underway so a new website is not yet available but you can can

The Santoms will take over production and sales of the single place Hawk models including the Part 103 model and the Ultra, a somewhat beefier model that is built as an Experimental Amateur Built (EAB). My discussion with Bob and LB was encouraging. I was impressed to hear the enthusiasm from father and son for keeping this series of Hawks available.

This is great news for Hawk fans. The two place models Terry Short and son have been assembling look great and will continue. This includes the FAA-accepted LSA model powered by the Rotax 912. Terry is busy enough that the single place models were lower on his to-do list so in stepped the Santoms who will assure the single place models get extra attention.

"We're located on an airport community about 60 miles from Terry's Lake Wales Airport location," said Bob.

This will make it easy on both enterprises as the Santoms will lean on Terry's fabrication abilities as they use many parts that are interchangeable between the single and two-seat models of Hawk.

"We talked to many Hawk enthusiasts at recent shows and we were pleased to hear of genuine interest in the single place models," Bob added.

As you can see by the bare bones Hawk they exhibited, the new operation is just getting underway so a new website is not yet available but you can can