The most popular article of this crazy year — when people have been visiting in record numbers — was about Aeromarine-LSA‘s Merlin Lite. Tens of thousands of you devoured this article within days of it being posted.

The most popular article of this crazy year — when people have been visiting in record numbers — was about Aeromarine-LSA‘s Merlin Lite. Tens of thousands of you devoured this article within days of it being posted.

The word sensational is vastly overused in modern American society but in this case the word fits the intense interest in Merlin Lite. For the back story, see the article in this link.

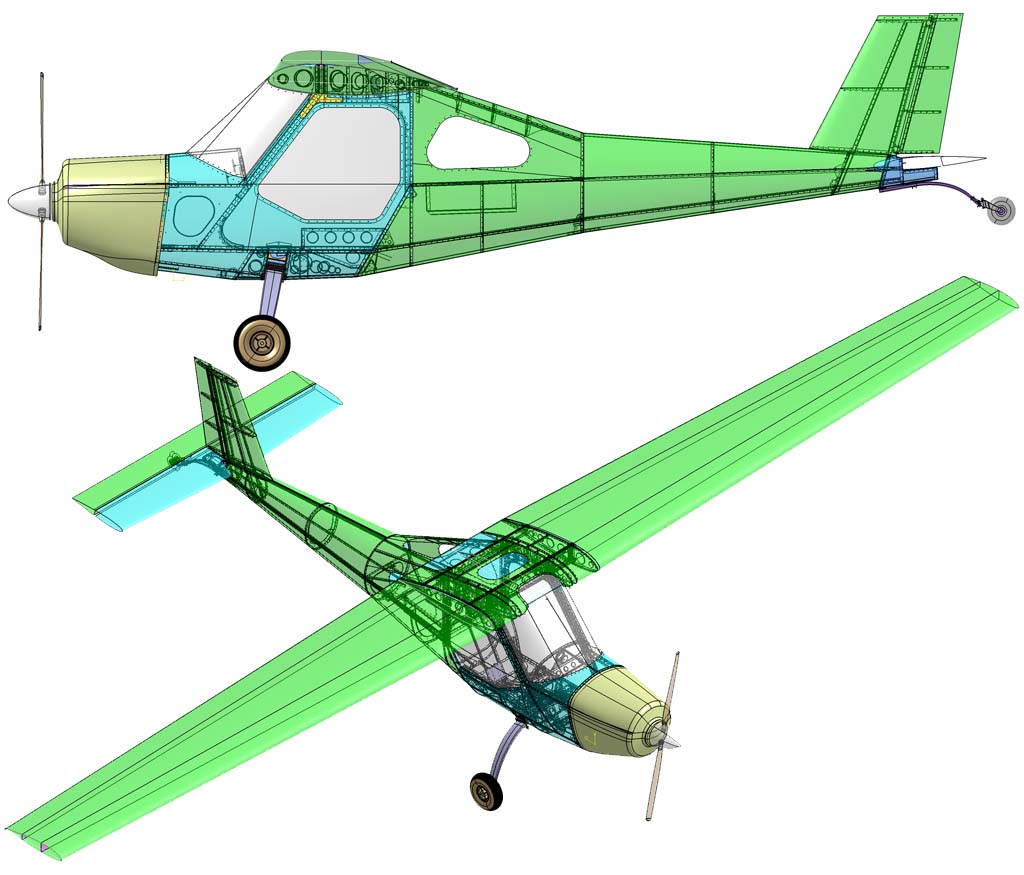

Despite obvious enthusiasm for this new Part 103 entry, many of you were skeptical. No wonder. An all-metal, fully enclosed aircraft does not closely resemble many of the other Part 103 aircraft that are selling briskly over the last few years. If you were among the doubters this post — and the video below — may serve to allay one of your concerns.

Weighing Merlin Lite

Developer Chip Erwin came to 2020’s Midwest LSA Expo prepared to tackle the hesitation in pilot’s acceptance of Merlin Lite as a legitimate Part 103. He brought six bathroom scales plus a fish scale to the show.

Aeromarine-LSA developer Chip Erwin enjoyed telling the many who checked out Merlin Lite that “it comes with seven windows.” It also has deep-deploying Fowler flaps that are known to be very efficient.

On opening day, I jumped at the chance to prove to myself and readers that Merlin could actually make weight.

To be thorough, weight is not the only consideration. Merlin must also make the speeds of Part 103: a 55 knot level flight maximum speed plus a maximum 24 knot stall. As you will hear in the video, Chip needs to tweak the configuration slightly to assure Merlin Lite does not fly nor stall above limits. He referenced 75 mph cruise speed and a slow speed of of 30 mph. Both are too fast, though just slightly.

In a longer video interview to follow, Chip states that he sees no problem in meeting the speed. Not going too fast can be controlled by the right prop setup, especially since the design is already close; top speed can likely be governed by a two-blade, pitch-oriented prop or other alteration.

Flying Merlin Lite

Within a short time of returning to his base of operations, Chip took Merlin Lite aloft for its first flight. The video below captures this and shows the aircraft performing well with its Polini Thor 250 engine.

Powered paragliders embraced the engine years ago and the company sells thousands of engines every year. Here is a page of full specifications on the Polini line from Miami-based Aerolite.

The video spells out some detail in the weighing exercise at Midwest 2020 and provides several clips of Chip’s first flight in Merlin. Enjoy…!

This video show views of the Merlin Lite but also the weighing of the aircraft, proving it can make Part 103 weight.

I hope Chip can make the weight! This “vehicle” is something I’m interested in. Even better would be the FAA changing the part 103 max weight to something like 275 lb. How they came up with 254 is beyond me. But the Merlin Lite is something I’d love to own!

Tom: FAA’s head rule writer for Part 103 said the empty weight of 254 pounds was somewhat arbitrary but was based on a survey of ultralights of 1982 when this rule was issued. Asking for any change whatsoever means evaluating the entire rule and doing so in the current high-regulation environment (2020 v. 1982) will surely invite a higher level of regulation. Advisory Circular AC-103-7 gives additional guidance to FAA field officers and allowed for more flexibility.

Dan;

Thanks for the insight!.

USA Part 103 Rules have been around for almost 40 years! If they allow more Weight, people will want more Gas, even Bigger Engines. Part 103 wasn’t designed for Cross Country Travel, but you can even on 5 Gallons! Most Part 103 even with just 5 Gallons have a Range of 80-120 miles. I average 21 Airports in a 50 mile radius of me out to 250 miles. The vast majority of Part 103 and even Small Kitplanes fall into the MTOW of 540 lbs which needs 32.8 hp to 660 lbs which needs 40.1 hp if you use the ideal Power to Weight ratio of 1 kw for 10 kg. Take the Lazair Ultralight MTOW 450 lbs as a good example. Flew marginally with (2) 5.5 hp chainsaw engines. Was soon upgraded too (2) Rotax 185 UL’s, which were rated at 9.4hp@5000rpm = 18.8hp, which I think was false, Rotax’s Engine site put’s them at 8.0hp@5000rpm = 16hp, but people were still not happy, so many upgraded to the Solo 210, 15 hp x 2 = 30 hp. If you use the 1kw for 10 kg formula, a 450 MTOW needs 27.4 hp/2 = 13.7 hp each needed. With the (2) Rotax 185 UL’s it still had an Empty Weight: 210 lbs (95 kg). So Air Frame upgrades were still possible. Part of the Lazairs performance problem was they used Poor Props and made some bad engine choices. My 1972 Skidoo 292 TNT Single made 20hp@6500rpm. The 1963-2004 Skidoo 250 Type 247 made 12hp@5500rpm. The Lazair came out in 1978. My T-Bird I has a MTOW of 660 lbs so a Part 103 at Max USA 254 lbs + 30 lbs (Gas) = 284 lbs allows for a Pilot up to 376 lbs. The Rotax 277 UL came out in 1978, is the smallest Engine I seen put on a T-Bird. The Average USA Pilot Weight falls between 180 lbs to 225 lbs. My T-Bird I is one of the Heaviest Tube & Fabric Planes and with a 447 UL weighs 280 lbs, it just makes Part 103 with a Rotax 277 UL, 28 hp (65 lbs). Could they cut off some weight 8-10 lbs, yes, if they tried. So with a Newer Hirth F-33 (28 hp) at 45 lbs with E Start, an MZ-34 (30 hp) 42 lbs, and a Simonini Mini 3 (30 hp) 44 lbs, it will easily make Part 103. An Aerolite 103 with a MTOW of 600 lbs with the Hirth F-33 comes in at 235 lbs. So 254 lbs – 235 lbs = 19 lbs they could use to improve the Airframe for a higher MTOW. So No, Part 103 doesn’t need the Weight changed, these different Manufactures need to Access their Airframe Designs and the Engines they Picked for them and what might be done to improve them both!

A weight increase to allow the use of a reliable four stroke engine is what is needed for safety. The use of “it will quit you” two strokes is a big safety concern.

A weight increase is highly unlikely. Even if such a petition did make its way through FAA, it would come out the other side with many other rules and restrictions. On the other hand, a well-maintained two-stroke will not suddenly quit. They need to be maintained differently than a four-stroke but are not inherently more unreliable.

Any Engine 2 or 4 Stroke Reliability depends on WHO Built it, WHO is Maintaining it, and Who is Flying it! I would say 99% of all Engine Failures is Human related. For Rotax 2 Strokes Failures, 85% is caused from Detonation, People using Old, Low Octane Gas. Gas can drop 2 Points in Octane in as little as 3 Weeks. Those who premix it drops faster. 2 Stroke Oil once mixed with Gas also has a Time Limit before it breaks down. Not all 2 Stroke Oils are the same, they have different Flash Points from 178 F to 500 F, the Higher the Flash Point the better. People don’t change out Carb Boots, their Fuel System parts. You also got the Standard Conventional 2 Stroke Oils and Synthetic Oils. Which the Synthetics can be used at 80:1, 90:1, 100:1 which means less Carbon buildup, so usually 700+ hrs before a DeCarbon is even needed. So Burn Pump 93 or 100 LL which is Best with the TCP treatment and use a Good Oil like Hirth’s Blue Max or Amsoils Saber Pro and 95% of your Rotax Engine Failures will go away. Change out your Carb Boots, and other Fuel System parts and your up to 99% Reliability. The 1% other Failures is people messing with the Jetting, not machining their Cylinders with a Torque Plate, not premixing right Ratio, etc. Using Quality Parts also Helps on Reliability. Like JBM makes the Best Carb Boots & Gaskets. I just seen a week ago a guy post a photo of his New Hirth Engines Carb boot that Failed Drastically at 80 hrs, so there goes that 1000 hr TBO. Most Rubber Carb Boots doesn’t like Ethanol in the Gas. Most New 2 Strokes for Plane use today have dropped their CR to 9.5cr today. Pump Gas is crap today.

What was the field elevation of the test? Would it still work up in the Intermountain West, you know – density altitude stuff. 🙂

Mt. Vernon airport is at 480 feet MSL. Weighing things in the mountains will make very little difference.

Every Plane with a Internal Combustion Engine is affected by Air Density. Like the Polini Thor 250 he is using is rated 36hp@7500rpm at Sea Level. If you were starting out at say 5000 ft that Engine would be making a BHP of 36 at Sea Level and Elevation of 5000 feet is 5.40 HP loss. So 30.6hp@7500rpm. With Part 103 it has to meet a 24 knot Stall with a 170 lb Pilot only. With say a 200 lb Pilot it will be higher, how much higher I don’t know. There is probably a formula out there. The hp@rpm to maintain Level Flight just above that Stall Speed usually takes on Avg 15-20 hp. Each Plane is going to be different, remember the Lazair Ultralight flew on 11hp, and cruised on less, I think 8hp. The Rotax 277UL rated 26hp@6250rpm was probably used on 85% of the Worlds Part 103 over 40 years and 6250 x 75% = 4,687.5rpm for Cruise and at 4750rpm it made 15.1 hp! At 4500rpm it made 12.3hp. If you start out at 5000 ft all the time you can raise the CR to make up the power loss. On Snowmobiles they Avg +2-3 Points in CR. The Smaller the CC Engine is the harder to make more hp. The Polini Thor is only 244cc and uses 11.5cr and a Tuned Pipe and puts the Plane over Part 103 by 3 lbs, so needs a $4,500 BRS to make Weight. The Plane easily makes Part 103 with a Hirth F33 which is 313cc, also with the MZ34 313cc, also with the Simonini Mini 3 that uses 270cc and 10.5cr with a Tuned Pipe. Their website says making 36hp@7000rpm, but I think it’s actually 32.2hp@7000rpm when you look at their Power Chart. If flying in the Mountains, you might want a BRS, but I would still use the Biggest CC Engine I could use and still make Weight. Even a 277UL 268.8cc Free Air could maybe be used with the BRS exemption. It can be Big Bored to 348.6cc & Stroked to 369.8cc. A 362cc Simonini Victor 1 with 9.5cr and a Tuned Pipe is 44hp! But it Weighs 70 lbs.

At MTOW of 600 lbs = 272.1554 kg / 10 kg = 27.21554 kw needed to Fly Well = 36.49664 hp to Fly Well! It all depends on what Altitude you’re starting out at. The Important Question is at what hp@rpm does your Plane Stall at? USA Part 103 is supposed to have a Minimum Stall Speed of 24 knots(27.6mph) with a 170 lb Pilot. The Heavier you are than 170 lbs means a Higher Stall Speed. Like 85% of the True Part 103’s (254 lbs) flew with a 26hp/28hp Rotax 277UL. The 26hp@6250rpm 277UL when Dynoed actually made Max 25.4hp@6000rpm. 25.4hp x 75% power = 19.05hp which it made 20.3hp@5250rpm.

BHP of 36 at sea level and Elevation of 1000 feet is 1.08 HP loss.

BHP of 36 at sea level and Elevation of 2000 feet is 2.16 HP loss.

BHP of 36 at sea level and Elevation of 3000 feet is 3.24 HP loss.

BHP of 36 at sea level and Elevation of 4000 feet is 4.32 HP loss.

BHP of 36 at sea level and Elevation of 5000 feet is 5.40 HP loss.

BHP of 36 at sea level and Elevation of 6000 feet is 6.48 HP loss.

BHP of 36 at sea level and Elevation of 7000 feet is 7.56 HP loss.

BHP of 36 at sea level and Elevation of 8000 feet is 8.64 HP loss.

Wallace Racing – Braking HP Loss at Altitude Calculator.

http://www.wallaceracing.com/braking-hp.php

minimum 24 knot stall –> maximum 24 knot stall

Thanks for the catch …corrected.

Isn’t it Minimum 24 knot Stall with a 170 lb Pilot to Qualify?

The best response I have is to check out AC 103-7, linked in the article.

Nice job Chip!

A thing of BEAUTY! You can do it Chip! Crossing my fingers for a complete success story :). I’ll be watching closely.

I didn’t see in your article the current MTOW. When I talked to [Chip Erwin] he was at 500 pounds which needs 30.4 horsepower, but he hoped after some testing to get [Merlin Lite] up to 550 pounds which need 33.4 horsepower using the 1kw-for-10 kg power to weight ratio. The Polini Thor is 36 horsepower at 7500 rpm, a +1000rpm more than industry standard which shortens its life to 200-250 hours from what I was told by a Paraplane shop that burns 100LL in them. It’s also 55 pounds complete which puts it over USA Part 103 by 3 pounds, which then needs an expensive $4,500 BRS [oarachute system] for the weight exemption*.

Can he pull off the door to make USA Part 103 weight without the BRS? Yes, but I think most people would want the door! He is only 3 pounds over with the Polini. A better choice of Engines would be the Hirth F33 (28 horsepower), MZ34 (30 horsepower), Simioni Mini 3 (30 horsepower) — all three weigh 42-45 pounds. The horsepower of all three of these engines can be improved with either a bigger carb, a better muffler, or a tuned pipe or combination.

One of the best singles on the market, also the most expensive is a Simonini Victor 1 Super, weighing 70 pounds, with 400cc displacement, using 9.5 cr, and rated 54 horsepower at 6500 rpm with a tuned Pipe! That is 400 cc dividid by 54 horsepower equals 7.4cc to make 1 horsepower. The Victor 1 is 362 cubic centimeters, outputs 44 horsepower, and the Victor 1 Plus is 382cc with 48 horsepower, both also 70 pounds. Ideally, a 2-stroke using 11.5 cr, proper size carb, and using 6500 rpm, with a well-designed tuned pipe it takes on average 7 cc to make 1 horsepower. Using 9.5 cr vs 11.5 cr averages 2 horsepower less, as 400 cc / 7 cc = 57.1 horsepower minus 2 horsepower for the 9.5 cr equals 55.1 horsepower, so nearly perfect. The carb is too small or it would make more horsepower. The Hirth F-33 (28 horsepower at 6500 rpm) is 9.5cr with a muffler, is 313 cc / 7 cc equals 44.7 horsepower at 6500 rpm with a good tuned pipe. With the 9.5 cr and small 34 mm carb, it would probably be around 40 horsepower. The Rotax 277 is 268.8 cc / 7 cc equals 38.4 horsepower at 6500 rpm and used a 36mm carb. Rotax exhaust are not tuned pipes, they’re a megaphone header with a muffler.

Very exciting!

Thanks for the follow up ?

Exciting ?

Love it

Possibly the most advanced Part 103 3-axis aircraft currently on the market.

Many thanks for this detailed report