What a great Christmas present for the Rotax Aircraft Engine team members (lower photo). The latest powerplant from the Austrian company that supplies a large majority of the powerplants for aircraft covered on this website will soon become available.

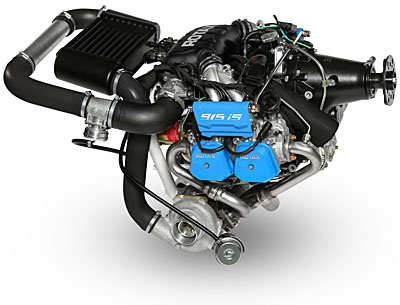

The newest Rotax engine is the 915 iS. Learn more in this video when it was announced.

The company announced from their headquarters in Gunskirchen, Austria that on December 19th, 2017, they received a European Aviation Safety Agency (EASA) Type Certificate (TC) for its new Rotax 915 iSc3 engine.

Some companies, such as BRM Aero, have been testing the new advanced, fuel injected, intercooled engine. It is the most powerful model ever for light aircraft from Rotax. All airframe makers will probably be surprised that the final version yields even more power.

“The EASA TC allows BRP-Rotax to [begin] producing the certified 915 iSc3 A engine for the European market thus allowing us to fulfill the request of our customers for a more powerful Rotax aircraft engine with proven reliability,” said Thomas Uhr, general manager BRP- Rotax, vice president Powertrain BRP. “Not only has the certification been achieved within the promised time schedule but the engine has been certified to even higher power than originally announced. Instead of 135 horsepower maximum power, the engine will offer 141 horsepower maximum power instead and 135 maximum continuous horsepower.”

Having earned approval from EASA — roughly the equivalent of FAA for the European Union — BRP’s Rotax team will concentrate on getting the FAA certification*. Other countries will follow as each has its own validation process.

The increased 141 maximum horsepower is available up to at least 15,000 feet, said Rotax making the Rotax 915 iSc3 A engine a perfect powerplant for all fixed wings, gyrocopters, and more.

“Up to this date,” Rotax noted, “12 airframe manufacturers — Tecnam, BRM Aero, Niki Rotor Aviation, BlackWing, and Zlin Aviation — have integrated the engine and will make aircraft available [with the new engine] very soon.” An additional 47 manufacturers are also already in the final stages of the integration of this engine.

With more than 180,000 engines sold in over 40 years, Rotax aircraft engines lead the Light-Sport and ultralight aircraft market. Worldwide, 19 authorized distributors and a network of more than 220 sales and repair centers support customers. “Rotax aircraft engines are supplied to more than 80% of all aircraft manufacturers in its segment,” claimed the company.

* FAA certification is different from demonstrating ASTM compliance. Rotax has long made sport versions and certified versions of their powerplants, so they can be used on a wider variety of aircraft. The engines are essentially the same but go through further documentation to achieve full certification.

HI Dan,

The TBO (at least for now) is listed 1200 hrs and I haven’t had a reply from Rotax after a couple of queries. Is this just an initial certification number with expectations for 2000? I’m looking very hard at a Sling 4!

I really enjoy your work and there seems to be more and more I find all the time!

Peter

We checked with Rotax. They confirmed the present TBO is 1,200 hours. However, they rely on real-time field testing — as opposed to engineering calculations or test bay results — before they increase the TBO (Time Between Overhaul). Rotax fully expects to increase the TBO to 2,000 hours when flight schools or other high-time users reach that point.

This new engine should be a game-changer for Rotax. There are plenty of gyroplanes and new-generation small 4-seaters (along with many other aircraft) that could really benefit from the extra 26 to 41 horsepower over a 912 or 914. Aside from the performance advantage, the extra measure of safety that comes with a tad more power will be welcomed …at least by this guy — who once flew in an underpowered gyro and never wants to repeat that experience again! 🙂

I’m really excited to see the airframes this power plant inspires. It’ll be interesting to see if the engines that started off for ultralights and sport planes can grow up make a big difference as certified airplanes.

I was told that this engine will only operate with a constant speed prop and that’s not allowed for SLSA in the U.S. Any feedback?

Hi Deon: I don’t know why the 915 would “only” work with an adjustable prop although such is a great idea and LAMA has approached FAA regarding the Single Lever Control system in which Rotax is one of three companies doing development work. I’ll inquire further.

Any news?

Hi Patrick: As you should have seen in our recent post about flying the 915iS, more news is now available, as promised.

I wonder if they will have bad pushrods like the new 912 that they won’t pay for !!!!!

Hi Steve: It appears you had an experience that suggests a conversation with a Rotax expert would be a good idea, perhaps at one of the airshows?