In the early 1930s, Sensenich began making propellers …from wood. Almost a century later, wood remains a very viable material for props and many recreational aircraft owners are happy about that because wood is light and less costly.

The company quartered only a few miles from Sun ‘n Fun introduced metal propellers in the 1940s, developed composite propellers in the late 1990s, and continues to push boundaries in the light aircraft, unmanned, and marine propulsion markets. For those unaware, Sensenich has built a substantial business making large diameter, very-wide-chord props for airboats.

Recreational and More

Sensenich is so common on the light aircraft that we cover on this website that some readers may not even be aware of the brand’s use on FAA-certified aircraft. Of the “well over 850,000 propellers” Sensenich said they have shipped, most went on certified aircraft. They know how to meet those regulations.

Video below shows aspects of the ground adjusting mechanism.

Recently, the company announced it was won a Supplemental Type Certificate (STC) for its carbon ground-adjustable pitch STOL propeller for Piper Super Cub Aircraft. An STC is required when modifying a certified aircraft; usually handled in the field to benefit a single aircraft.

This new STC allows installation on PA-18 “150” aircraft powered by Lycoming O-360 series engines, with future STCs planned for Lycoming O-320 powered Super Cubs and certain popular training aircraft.

“Our Experimental Amateur-Built aircraft customers have been raving about this propeller for several years, and now we can offer the same step up in performance to our certified customers,” says Sensenich president, Don Rowell.

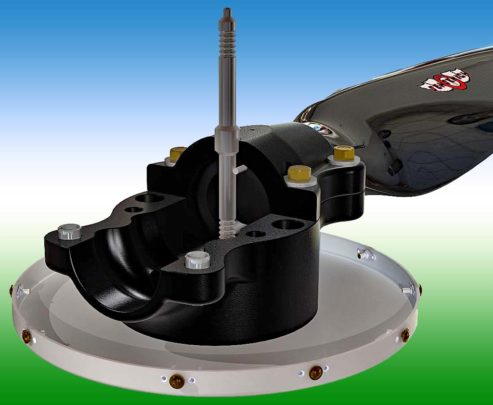

Don continued, “This propeller’s quick and sure pitch adjustment (nearby image) gives the customer the option of maximum performance no matter what the flight profile may be.”

Want to see those fat props work? Watch the video below and check the acceleration of one airboat.

Sensenich reported that extensive testing required during the certification project in Alaska showed improved take-off, climb and cruise performance compared to what’s considered the industry standard fixed-pitch STOL propeller.

“When pitched for the same climb rpm as the standard propeller, climb rate was increased by 140 feet per minute, cruise speed was identical, and full-throttle level-flight speed increased by seven miles per hour. When repitched to match the industry standard propeller’s climb rate, cruise speed was increased by eight miles per hour and full-throttle level-flight speed increased by 18 miles per hour.” These substantial gains appear to show the recreational aircraft industry that has used these props have long enjoyed improvements that factory-built, FAA-certified aircraft wanted.

Sensenich’s new composite propeller is listed at half the weight of the legacy STOL propeller: 21 pounds for the new Sensenich prop versus 44 pounds for a metal unit.

The propeller is available in diameters from 78 inches to 82 inches. The STC also covers a 12-inch diameter balanced composite spinner.

This STC will be available for new-build propellers starting the first quarter of 2021. Pricing for the propeller with STC documentation is $6,350 FOB Plant City. Adding the spinner brings the price to $7,085 including STC documents.

While Sensenich continues to open new markets for their well-received propellers, they remain a leading supplier to the Light-Sport Aircraft, Sport Pilot kit-build, and ultralight segments.

When did you guys improve the profile of the composite ground adjustable prop for the 0-200 to improve cooling?

Go directly to the source: Sensenich Propellers. They can best explain their technology.