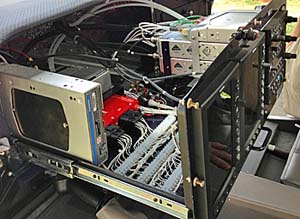

World Aircraft Company boss Eric Giles shows off their nifty panel configuration.

Elements are basic components of nature. As in our first two parts, I see Oshkosh Elements as worthy ideas other than airframes or engines. One such is World Aircraft Company‘s roller-bearing pull-out drawer instrument panel. Now, if you are like me and don’t spend a lot of time around your airplane with a wrench or soldering iron in your hands, you might not see why this is important. For panels with a collection of round instruments, maybe it isn’t as fetching an idea. Yet I’m willing to guess that nearly every mechanic who reads this or hears of World’s innovation is going to say, “Yes! Why hasn’t this been done before and why aren’t all instrument panels done this way?”

Early this year, I watched while two avionics mechanics maneuvered around the instrument panel in a Flight Design CTLSi. Their task was to install ADS-B hardware to coordinate with the dual-screen Dynon SkyView that fills left and right bays of the instrument panel. To make the installation, almost everything had to be removed so that a box could be installed forward of the Dynon screens. In short order, the seats and floor of the cockpit were littered with screens, wires, screws, brackets and other assorted parts. Then, with all this in their way, the two technicians had to practically stand on their heads in the most awkward poses in order to get tools where they needed to be. Despite their contortions, some parts were still hard to handle as they simply couldn’t put any more hands on the job. Though I planned to watch the entire process to better understand it, after three hours I was worn out even without lifting a finger.

I thought, Gosh, this looks so difficult; they really need the hinged instrument panel I’d seen in one design, or the removable upper panel from a couple other LSA. Little did I know what Eric Giles and his crew were doing at the Paris, Tennessee airport that is home to World Aircraft and their Spirit SLSA. As the photos show, they took another approach, installing hardware that with a slight pull on the handle — after removing a few securing screws — presents all the panel insides for the easiest access I’ve seen. It appeared a mechanic could merely sit in the pilot’s seat and do what he or she needed to do. As a result, or perhaps because World employs tidy mechanics, all the wiring and bracketry looked very sanitary. Updating the digital instruments would be simpler although a USB port mounted in the panel makes database updating even easier. Well done, World Aircraft!

An additional observation … See the bright red box? (You can hardly miss it!) This is the Vertical Power Electronic Circuit Breaker (ECB) controller. It took me a couple lessons to understand its function — remember, I’m not a mechanic or engineer — but I have become a true believer in this arcane-sounding but important concept. Instead of a row of circuit breakers, all with electrical power traveling to and fro, the ECB provides modern solid state circuit control. This comes with numerous benefits that you can see in our earlier report, or in our video, or you read Vertical Power’s technology overview. If you are home building or when you talk to a manufacturer, consider Vertical Power’s hardware. As company owner Marc Ausman says, “Our main competition is the old way of doing things.”

Leave a Reply