You’ve heard of the Risen, Alberto Porto’s sleek, fast retractable that makes the most of its Rotax 912 power. With more than 180 mph on tap with the 912 iS, the Risen seems the perfect two-person traveling machine. It’s also one, like the Sparker, that would fit well into the new MOSAIC rules. Well, Porto and Andrea Venturini are going to find out just how well it travels this summer. They’ve announced a “unique, record breaking flight across the Atlantic Ocean.” Only this Risen will be using the latest Rotax 916 iS, the turbocharged, 160-hp engine so many airframers are now fitting in place of the 915 iS. For Porto and Venturini, “the plan is to cover 3200 kms or about 2000 statute miles across the Atlantic Ocean with a fuel consumption of just over 50 gallons of fuel at speeds up to 230 mph.

There’s little question

There’s little question

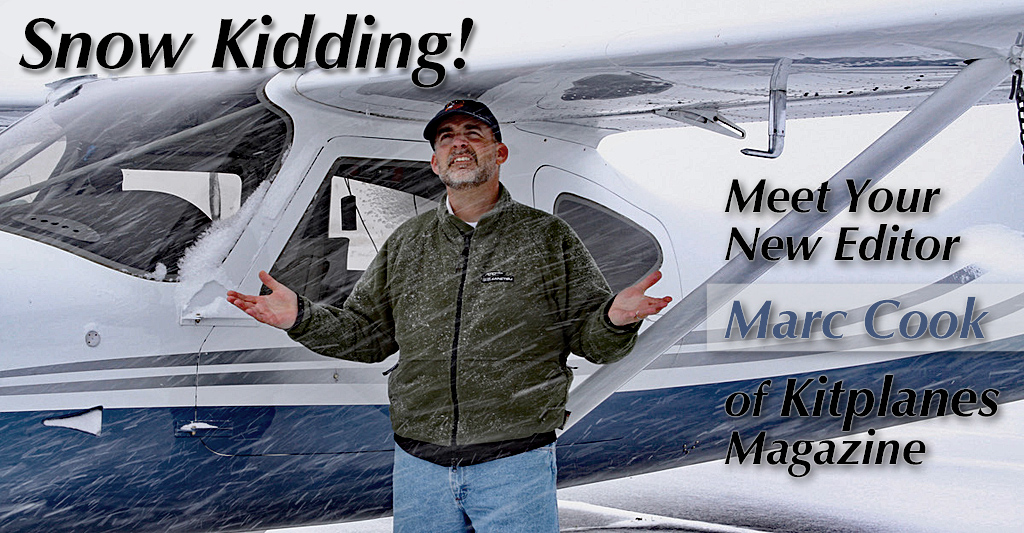

Speaking of KITPLANES, that’s where I come from. In fact, Dan and I have history—the good kind—as he wrote about the then-nascent LSA category for KP back when all this got started. We felt it was important to get smart about the segment since it would intersect with Experimental aircraft. How, exactly, we weren’t sure but it did seem that many existing makers of kits would jump at the chance to series-build airplanes (and they did) and that we might just get some coming the other way (not as much). In any case, even though my recent activities haven’t been so directly involved with production SLSAs, I’ve kept a keen interest in them. So taking over for Dan here represents a comfortable and exciting expansion to my duties over at KITPLANES.

Speaking of KITPLANES, that’s where I come from. In fact, Dan and I have history—the good kind—as he wrote about the then-nascent LSA category for KP back when all this got started. We felt it was important to get smart about the segment since it would intersect with Experimental aircraft. How, exactly, we weren’t sure but it did seem that many existing makers of kits would jump at the chance to series-build airplanes (and they did) and that we might just get some coming the other way (not as much). In any case, even though my recent activities haven’t been so directly involved with production SLSAs, I’ve kept a keen interest in them. So taking over for Dan here represents a comfortable and exciting expansion to my duties over at KITPLANES.

Eventually, career opportunities led me back to motorcycling, then back to airplanes again in 2004 when I was offered the big seat at KITPLANES. I got spooked by the economic issues at the end of the decade and swiveled to playing with two wheels before being lured back in 2018. I’ve been editor in chief of KITPLANES since then, and now add this website to my list of responsibilities.

Eventually, career opportunities led me back to motorcycling, then back to airplanes again in 2004 when I was offered the big seat at KITPLANES. I got spooked by the economic issues at the end of the decade and swiveled to playing with two wheels before being lured back in 2018. I’ve been editor in chief of KITPLANES since then, and now add this website to my list of responsibilities.

Harley Davidson or Rotax — Sounds can be unique and associated with a certain brand. Harley motorcycles have made their sound a trademark, defending it vigorously against wannabe knock-offs.

Harley Davidson or Rotax — Sounds can be unique and associated with a certain brand. Harley motorcycles have made their sound a trademark, defending it vigorously against wannabe knock-offs.

(SPA) at the

(SPA) at the  Although SPA worked hard at community outreach, noting in part that it already used aircraft that operated well under the airport’s noise limits and burned relatively little unleaded autogas (thanks to the Rotax 912 iS engines), complaints continued. At one point last year, SPA management had to fight being kicked off the airport entirely. They needed to do something to go “above and beyond” in order to keep the school running and, indeed, growing.

Although SPA worked hard at community outreach, noting in part that it already used aircraft that operated well under the airport’s noise limits and burned relatively little unleaded autogas (thanks to the Rotax 912 iS engines), complaints continued. At one point last year, SPA management had to fight being kicked off the airport entirely. They needed to do something to go “above and beyond” in order to keep the school running and, indeed, growing. “We started by changing our procedures,” says Liknaitzky. “We then started reminding people that we had the quietest airplanes on the field. We never busted the noise monitor. But in multiple meetings with the community, we started to listen to what they were saying. They started describing the sound of our airplanes. They said it’s not that our airplanes are loud but the nature of the sound was annoying. This was a turning point for us. We told ourselves that we have to look at the sound quality, not just the quantity.”

“We started by changing our procedures,” says Liknaitzky. “We then started reminding people that we had the quietest airplanes on the field. We never busted the noise monitor. But in multiple meetings with the community, we started to listen to what they were saying. They started describing the sound of our airplanes. They said it’s not that our airplanes are loud but the nature of the sound was annoying. This was a turning point for us. We told ourselves that we have to look at the sound quality, not just the quantity.” After significant study, Sling realized that it wasn’t just the higher frequency sound the combination produces but that it wavered as well, likely the result of acoustics and the Rotax’s high-rpm nature. And they had to get on with a solution because “we’re adding 30 airplanes this year, and we already have 40 in the fleet,” says Liknaitzky.

After significant study, Sling realized that it wasn’t just the higher frequency sound the combination produces but that it wavered as well, likely the result of acoustics and the Rotax’s high-rpm nature. And they had to get on with a solution because “we’re adding 30 airplanes this year, and we already have 40 in the fleet,” says Liknaitzky.

Surprisingly, the system appears to actually improve the Sling’s performance. The company assumes that the stock Sling-built exhaust actually had too little backpressure and so the new, quieter system gives the Rotax more of what it needs.

Surprisingly, the system appears to actually improve the Sling’s performance. The company assumes that the stock Sling-built exhaust actually had too little backpressure and so the new, quieter system gives the Rotax more of what it needs.

https://www.youtube.com/watch?v=njW_CJBuuJI

https://www.youtube.com/watch?v=YXAIKmpwDJ4

https://www.youtube.com/watch?v=njW_CJBuuJI

https://www.youtube.com/watch?v=YXAIKmpwDJ4