Editor’s Note: This story originally appeared in KITPLANES magazine but since so much of the LSA world depends on Rotax engines, we thought this was worth a read here.

Thirteen years into my two-year SeaRey build, OspRey finally had its engine mounted. But when I signed on the dotted line for my new Rotax 914, and with little more knowledge than how to change the oil in my car, I was nervous about my abilities to maintain this expensive engine. Because of this, back in 2014, I attended a weeklong service and maintenance class at Canadian Rotax distributor Rotech Motor, Ltd. Thanks to an excellent hands-on instructor, who acted like he had all the time in the world and a bagful of instructor tricks to teach us, by the second afternoon I had dropped my skepticism and distrust of the price/power ratio of the Rotax engine and was (almost) ready to go out and get a Rotax tattoo.

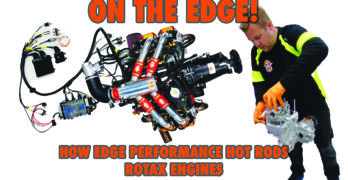

Hot-Rodded Rotaxes? That’s What Edge Performance Is All About

Editor’s Note: Recent commentary on the future of Rotax engines brought out a few comments that high-spec versions of the 900-series engines already exist, just in the aftermarket. For a deeper dive into the topic, here’s a story that ran in early 2023 in KITPLANES from Eric Stewart, a regular contributor to that magazine. Prices for Edge’s modified engines run from 26,000 Euro for the 108-hp EP912i to 45,000 Euro for the 180-hp EP917Ti.

Edge Performance of Notodden, Norway, has been around for little more than a decade, but their EFI and Rotax upgrades have quickly become popular, setting a high bar with race-quality components. I’ll be putting the EP912sti in the SR-1 race plane—not only does it have exceptional power to weight (important given the 661-pound weight limit for the SR-1’s record category), but racers go best when it’s hot and high—and the EP912STi’s turbo ensures we can still make power in those conditions.