High Speed means controlling cooling airflow

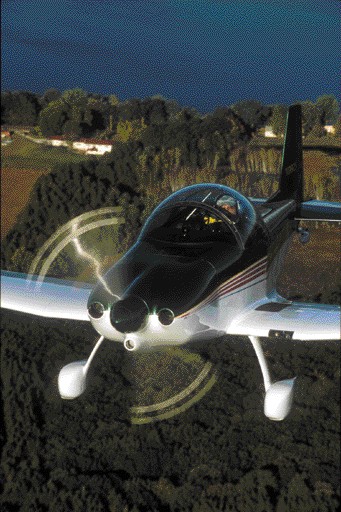

Wheelpants are racer Klaus Savier’s design; installation on the Mustang II added a few more mph.

According to Brian Schmidtbauer and Dave Anders, better cooling-not more power-equates to more speed.

s Anders, an RV-4 pilot and Schmidtbauer’s friend, designed the air inlets, as they are the first step in cooling airflow.

Schmidtbauer’s Mustang II features a ducted exit precisely shaped around the engine exhaust, and a small tube in the center of the exhause pipe releases excess engine oil.

Ramps and ductwork around the engine are carefully planned, and the firewall has been curved to help engine compartment air flow toward its exit point.

This Mustang II has out-raced Lancairs and RVs-Schmidtbauer has lost only one race.

Schmidtbauer estimates that he has put more than 2500 work hours into his Mustang.

When most of us think about a fast airplane, we sketch in our minds a sleek and smooth exterior and wings that allow the graceful machine to slip through the air with the least possible resistance. We think the engine is also important and that more power is better than less.

But according to race winner Brian Schmidtbauer, up to 30% of the total drag in an aircraft can be cooling drag, or air movement through the engine compartment.

Because I often review gliders and slower powered aircraft, I’m sure I displayed a slack-jawed response to this comment. The stunned expression stayed on my face as Schmidtbauer described detail after detail about the handling of cooling air.

After an hour-long flight in his blazing Mustang II, I came away a believer. His homebuilt aircraft has beaten the likes of jet-smooth Lancairs and isn’t threatened by speedy RVs. In fact, only his buddy and RV-4 pilot Dave Anders has beaten Schmidtbauer in a race, and they’re so close that the next race might be different.

The Quest for Speed

On a beautiful Minnesota fall day last October, Schmidtbauer let me take the controls of his Mustang II as we hurtled along close to 250 mph. It’s the fastest I’ve ever flown in an aircraft of this size.

Schmidtbauer is a resident of Anoka, Minnesota, where he owns a full-service car wash business. He also farms, and fall is harvest time. Any pilot might guess that while I pulled him away from a long day of harvesting crops, he enjoyed the chance to show off and fly his speedy airplane.

He wasn’t always such a streak in the sky. Schmidtbauer is a former ultralight pilot who’s also sampled sailplane soaring. He flew an American Aerolights Eagle ultralight for several years and loved it. He still speaks of it fondly even while zooming across a patchwork of farm fields in his Mustang II.

Schmidtbauer spent four and a half years building his Mustang II. When I asked about his hours log, he was quick to say the factory estimates 1300-1800 hours are required to complete the airframe. With so many performance modifications, Schmidtbauer put more than 2500 hours into his Mustang II.

Anders helped with many of the modifications used on the Mustang II. “Dave freely gave me many hours of his time,” Schmidtbauer said. Anders is the builder of what may be the world’s fastest RV-4. As it uses the same Lycoming IO-360 engine that Schmidtbauer has, his ideas were readily transferable.

In pursuing his super fast RV-4, Anders researched NACA reports back into the 1920s and Horner’s book on fluid dynamic drag and found that engine compartment air inlet versus air outlet should be a certain ratio. Years ago it was thought that the outlet should be 150% of inlet because expanding warm air requires more space.

Schmidtbauer said that to use a larger cooling air outlet is tantamount to dumping the air without any real effort at control. The modern goal is to use that departing air to give you an extra boost (and to move air smoothly through the engine compartment). By fine-tuning this ratio and efficiently achieving it, Anders and Schmidtbauer have reached speeds unheard of in similar machines with the same or even larger engines.

Anders’ experiments over many years suggest that 78% is the right ratio, with the inlets being larger. The logic may elude you, sounding instead like a recipe for more, not less drag with the air ramming into an engine compartment and being restricted on its exit. Interestingly, Schmidtbauer’s engine doesn’t run hotter, as you might expect. “I actually noted cooler temperatures after the changes were made even though the inlet volume was reduced by 35%,” he reports.

In fact, through the use of the venturi effect, you can actually gain thrust from air leaving the engine compartment, Schmidtbauer said. The air outlet of his Mustang II is carefully shaped to enhance the venturi and further augmented by using a ducted exit precisely shaped around the engine exhaust. Doing so allows Schmidtbauer to employ engine-accelerated exhaust to amplify the venturi effort. Call it Bernoulli’s Theorem on steroids.

There’s More to It

Inlets and outlets aren’t the whole story. The entire engine compartment has been carefully evaluated to assure the smoothest flow of cooling air. The air inlet shapes were designed by Anders and are an important first step in the cooling airflow. Ramps and ductwork in and around the engine were thoughtfully devised. Even the firewall, nearly always a flat surface in aircraft, has been strategically curved to help the engine compartment air flow easily toward its exit point. “Like water, air doesn’t like 90° turns,” Schmidtbauer said.

While he was designing and building, Schmidtbauer used another idea: He uses a small tube sitting in the center of the exhaust pipe to release excess engine oil. This effectively burns up any surplus oil so it doesn’t stain the underside of his aircraft. Indeed, his was clean.

Schmidtbauer is driven by the need for speed. In one remarkable winter, after taking advantage of Anders’ work and designer Klaus Savier’s pressure-recovery wheelpants, Schmidtbauer added an amazing 15 mph to his top cruise speed. That year’s magic combination dealt with cooling inlets and outlets, a changed engine cowling and a prop modification where Schmidtbauer gently radiused the tip. Again, Schmidtbauer borrowed from speed consultant Anders, whose knowledge was amplified by developments of the Nemesis Formula 1 air racing team.

Early Mustang IIs were plansbuilt machines. Owners had to do complex tasks such as rolling the leading edges. The homemade nature of this work kept many of those machines below the 200-mph barrier. “Some only managed 180 mph,” Schmidtbauer said, though his own Mustang II can fly 39% faster using the same exterior shape.

Workmanship was part of the reason those older models weren’t as swift, but speed mods are required to go way past 200 mph. Builders must realize that it takes dedication, smarts, research, careful building, and a relentless pursuit of speed to get into Schmidtbauer’s league. He always wanted a truly fast Mustang II. “It had to hit 200,” he said, “or it would have been in Trade-A-Plane the next week!”

More Help

Larry Kinder, a Northwest mechanic and fellow Mustang II speed buff, was another motivator. Kinder’s project was the 1981 Oshkosh Grand Champion. In 1998, Kinder hit 235 mph flying his Mustang II in the Aircraft Spruce Sun 100 race. When Schmidtbauer and Kinder flew together in the 2003 edition of the race, Schmidtbauer bested his friend, just exceeding 250 mph. Schmidtbauer admits he doesn’t know for certain, but he thinks his Mustang II is one of the fastest in the world. Maybe the fastest.

In his ongoing quest for speed, Schmidtbauer may raise the turtledeck to connect airflow aft of the cockpit canopy better. The trailing edge of the canopy drops too sharply. The ideal angle, he says, is 7.5°, confirmed by his tuft testing to identify the point of separation. “That’s a big undertaking, though, and I’m not ready to start right now,” he said.

Even in present form, Schmidtbauer’s Mustang II is a clean machine. Schmidtbauer’s razor-sharp focus on detail inside the engine compartment only adds to the work of his clean exterior. The wing looks like a composite surface. All rivet heads have been filled with a product called Superfill. The specialty material is “about a third the weight of Bondo and lasts far longer because the epoxy substance doesn’t shrink as much,” Schmidtbauer said.

Measuring Performance

The Sun 100 race is not typical flying. It’s flat-out, throttle-to-the-panel racing where the clock begins from a standing start and goes for 100 miles (translating to about 20 minutes of wide-open flying time). Schmidtbauer had legs of 248 mph and 256 mph, which includes acceleration from standstill. (One hint he divulged: Stay within a half wingspan of the runway as long as possible after liftoff.) In truth, Schmidtbauer said his Mustang II accelerates so fast that he’s hitting 200 mph in a short time and therefore a standing start doesn’t affect average speed over 100 miles as much as it would over a 10-mile course.

But race results are not ordinary flying. My goal was to see what an everyday Mustang II pilot might experience if he built his airplane to Schmidtbauer’s design specs.

On the day we flew, air temperature was about 50° F with low humidity, and the air had dissipating thermal lift. Our speed tests came at 7500 feet msl.

Blazing speed requires a strong engine but not one unusually powerful. According to Schmidtbauer, the rule says you gain 2% in speed for every 10% increase in power. It’s no wonder pursuit of lower drag pays off better than adding power. “It’s not about engine power; it’s about air drag,” Schmidtbauer said.

His Lycoming IO-360 puts out slightly more than 200 hp and gets reasonable fuel economy. Schmidtbauer and I noted about 12 gph during climbout (at 2000 fpm). Leaned at 7500 feet, fuel flow dropped to about 9 gph with cruise well above 200 mph. The Cessna Hawk XP I fly with a similar engine burns fuel at a similar rate but at a 50-60 mph slower cruise speed.

On our northerly upwind run at 7500 feet, we saw 215 mph on Schmidtbauer’s Bendix GPS at 24 inches of manifold and 2400 rpm. On the subsequent downwind run we saw 250 mph for an average of 232.5 mph. Going higher produces even better numbers. Schmidtbauer said, “It really likes to run fast up high.” He usually flight plans for 10,000 feet. No wonder, with less than 5 minutes of climb to reach that altitude!

Cruising

On one longer cross-country flight to a Tennessee NASCAR race, Schmidtbauer and his uncle flew 845 miles in 3 hours and 45 minutes while achieving 29.5 miles per gallon. At times, Schmidtbauer flew with only 15 inches of manifold pressure while enjoying a 20-mph tailwind. The Mustang II averaged just over 225 mph while burning only 8 gph. He arrived with 7 gallons left, using just 30 gallons on the nonstop flight. Sure, the tailwind helped, but Schmidtbauer’s Mustang II moves out even in economy mode.

Forward speed isn’t the only exciting benchmark in flying his machine. Climb off the runway hit nearly 3000 fpm, stayed at 2500 fpm for a thousand feet of sustained climb, and didn’t drop below 2000 fpm. You can get to 10,000 feet in 4-5 minutes.

The Ram Air/Push On control right in the center of the panel (below the GPS unit) controls a butterfly valve just under the prop hub. He closes this while on the ground to avoid getting dust and grit in the engine but opens it aloft. He says that when you open it, you can actually feel the airplane surge forward.

In more ordinary cruising, Schmidtbauer sets the prop at 2275 rpm and full forward (21 inches) on the throttle at 10,000 feet. At this setting he sees 230 mph.

This Mustang II has electronic ignition on one side and a magneto on the other. When checking the electronic side, no mag drop is noted, and Schmidtbauer says it compensates for timing changes by monitoring manifold pressures and revolutions as you ascend.

Harnessing the Performance

Any pilot can appreciate high speed. Most of us who fly cross-country feel we never see a number on the GPS or DME that is too high. But some designs that are faster than blazes are too much for most of us to handle. Flight characteristics are part and parcel of gaining the highest level of performance.

Whatever I fly, I always do a maneuver called Dutch rolls. These are not aerobatic. Instead they are used as a coordination exercise because they can involve doing full control applications with regular reversals. This simple effort lets me learn a lot about a plane’s handling. While doing Dutch rolls in the Mustang II, you need a little rudder to initiate the turn after which you use hardly any. “You could fly this airplane with your feet flat on the floor,” Schmidtbauer said. Within moments I was able to do ball-in-the-center Dutch rolls to 30-40° bank angles while keeping the longitudinal axis on a consistent line.

In my steep turn practice at 50-60° of bank, I tended to pitch up initially. Schmidtbauer thinks this happens because the view over the nose is very good, so pilots initially tend to bring up the nose to a more typical attitude. Later I had no problem at all, but on the first go-round I gained 1000 feet in a short time.

Light stick pressures are noted. So perhaps it’s no surprise that Schmidtbauer has a full autopilot installed in his Mustang II. Not only does it make a longer flight easier by relieving pilot workload, it adds to the aerodynamic efficiencies needed to reach high speed with a relatively small engine.

The Mustang II also goes slow surprisingly well. Set at 13.5 inches and with a notch of flaps (100 mph maximum), we flew about 80 mph. With full flaps and the same power, we got to 65 mph where we still had full control.

We experimented with the throttle at idle thrust and the propeller to maximum coarse (prop control back) to reduce disk drag. At this point on a smooth, beautiful evening, we showed 300-400 fpm of descent rate. The lowest sink rate seemed to come at 80-85 mph, slightly slower than the factory’s recommended 90-mph best glide speed. Given the small tapered wing that goes so fast, the Mustang II can also descend slowly, evidence of hard-working airfoil.

Stall came just below 60 mph and was preceded by a distinct shaking that felt as if we were driving on railroad ties. You should never miss the onset of stall in this Mustang II. Schmidtbauer didn’t care to have me do a full-break stall as he said we would be looking at the ground and accelerating toward it.

The Mustang II is fast enough that you must think ahead of the airplane. In the landing pattern, Schmidtbauer slows to 100 mph for flap speed. Once he slows to 90 mph, he adds the second notch of flaps. On base leg he puts down full flaps and slows to 80 mph on final approach.

Our second takeoff came with rotation at 80 mph using a conventional taildragger technique of stick forward liberally followed by a gradual return aft. All the while, you add power smoothly. Pattern climbout was done at 100-105 mph. The deck angle is not particularly steep, especially considering the climb rate.

When the flaps first came down, a buzzing could be heard. This turned out to be the Mylar gap seals Schmidtbauer had installed on every surface of this Mustang II. On the center-fuselage-crossing flap, the Mylar assures a tighter seal against the airplane’s belly—all part of Schmidtbauer’s extensive effort to eradicate drag.

Need for Speed?

Schmidtbauer looked at a variety of designs but he wanted the fastest-flying kit he could build. It also had to be affordable, he judged, and his 250-mph Mustang II cost him roughly $50,000 plus his labor. Does this sound like a bargain?

The basic kit is less than $10,000, and Mustang Aeronautics sells the IO-360 that Schmidtbauer used for around $30,000. A prop will cost $5000 more, so on Schmidtbauer’s budget, that left only about $5000 for instruments, paint, interior and everything else. Obviously Schmidtbauer built as efficiently for price as he did for speed. But even if you hit $60,000, that’s a good value for an airplane considerably faster than 200 mph (while getting close to 30 mpg).

Schmidtbauer had more than 2500 builder hours in his Mustang II, but most builders don’t count the value of their toils.

The factory offers several quick-build kit options. Take them all and you add about $10,000 to the base airframe kit price in exchange for shaving hundreds of hours from the 1800 hours that Schmidtbauer thinks is average.

Mustang Aeronautics, based in Troy, Michigan, has an extensive list of kit configurations, options, accessories, engines, props and more.

With 35 years of experience in the marketplace, the company reports about 800 aircraft flying including the Mustang II and the single-place Midget Mustang. The company’s success is no surprise to me. Blasting along comfortably at 235 mph was invigorating, yet a slow stall speed indicates most of us could fly the Mustang II competently.

FOR MORE INFORMATION, contact Mustang Aeronautics at 248/649-6818; e-mail mustangmail@mustangaero.com; web www.mustangaero.com.

| Seating | 2, side-by-side |

| Empty weight | 1,105 1 |

| Gross weight | 1,600 2 |

| Wingspan | 24.3 feet |

| Wing area | 97.1 square feet |

| Wing loading | 16.5 pounds/square foot |

| Useful Load | 495 pounds |

| Length | 19.5 feet |

| Cabin Interior | 40 inch width |

| Height | 5.5 feet |

| Fuel Capacity | 25-61 gallons 3 |

| Baggage area | 80 pounds |

| Notes: | 1 equipped as Schmidtbauer’s Mustang II 2 flown in normal category, the factory allows up to 1850-lb. gross, but only if the additional weight is fuel in the wings; aerobatic category limits gross weight to 1350 lb. 3 37 gallons in aircraft tested All specs and performance were provided by the factory and assume a conventional Mustang II kit with a 200-hp engine. Figures stated in the article were for Schmidtbauer’s customized Mustang II. |

| Standard engine | 200-hp Lycoming IO-360 |

| Power loading | 8 pounds/horsepower |

| Max Speed | 230 mph 1 |

| Cruise speed | 220 mph |

| Stall Speed | 58 mph |

| Rate of climb at gross | 1,900 fpm |

| Service Ceiling | 20,000 feet |

| Takeoff distance at gross | 470 feet |

| Landing distance at gross | 680 feet |

| Notes: | 1 for 200-hp engine; 210 mph with 160-hp engine |

Hi, I was wondering how I’d get in touch with Brian & Dave?

Hi Quentin: I regret my contact info for those people are dated and no longer applicable.