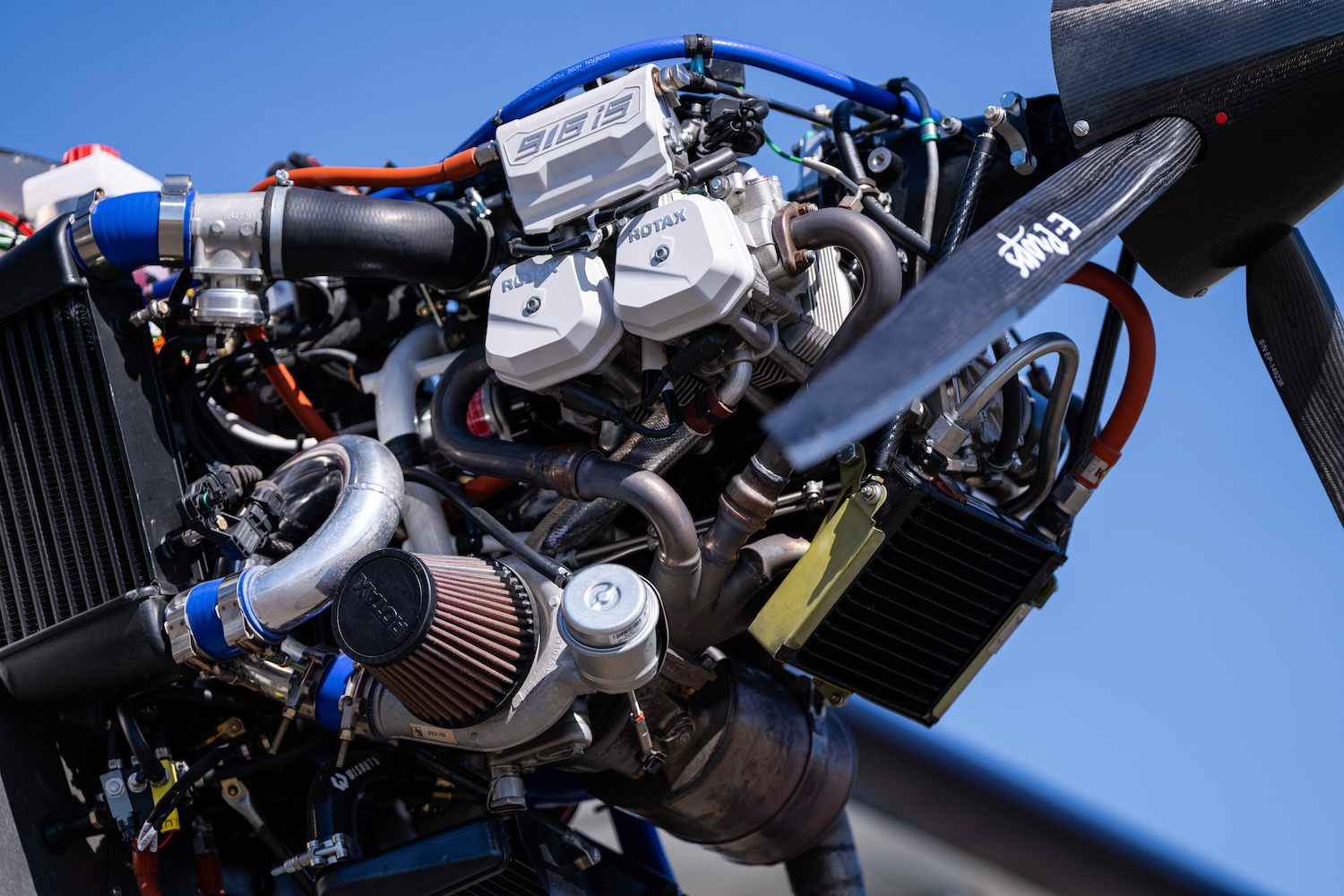

The Rotax 916 on the Carbon Cub UL (Jon Bliss photo).

Untethered prognostication is what you do waiting for the rain showers to blow through and the sun to reemerge on your long cross country. Me? I sorta do it for a living. (Such as that is.) And I get to do it often enough in front of people who work deep in the industry to see if I’ve landed close to the truth. Like playing Battleship with engineers and PR people.

My latest prognostication jag centers on what’s next for Rotax. And it’s driven by a feeling that there’s no time to waste moving up the horsepower ladder. Here’s my argument.

First, the traditional engine manufacturers have still not recovered from what they say are pandemic-related supply-chain issues, which causes huge delays in deliveries and helps drive prices quite high. In the Experimental realm, where I also live, new engines have become exceptionally more expensive, leading some builders to reassess their budgets and stop their projects where they stand.

Second, Rotax has scored a big hit with the 916. Yes, it’s also expensive, but that extra increment from 141 to 160 hp has opened the door to new performance in several designs that were good on the 915 but are significantly better with the newer engine. Some of those airplanes would be even better with more power.

Third, Rotax takes the world view that its products have to work around the globe, which means they can’t depend on 100-octane fuel. In the next slot up, which I’ll call the 200-220 hp range, we basically have traditional aircraft engines that require big octane to make power. You could, of course, run an even bigger Lyconsaurus at a lower compression ratio but the power-to-weight figures get even uglier. So a Rotax product at this power level that could use, say, the equivalent of a high-octane auto gas (as the 916 does) would be a huge win and provide owners with the option of using auto gas, the currently available 94-octane unleaded avgas that’s sparsely available or something else. Point being that any future engine should be not designed to require 100LL.

Some Perspective

It’s worth looking at where the Rotax line currently fits to help see a potential future. Of course, the 900-series engines are small four-stroke, flat-four engines with a gear reduction drive and liquid-cooled heads. The gear drive allows these small engines, which displace just under 83 cubic inches, to rev higher and make more horsepower. Our traditional engines, unburdened by gearboxes are, in effect, burdened by the inability to rev much higher than 2700-2900 rpm with any usefully sized propeller. As anyone who bases at an airport with a Cessna 185 present, as I am, you know that a big Continental spinning 2850 rpm for takeoff with a large propeller is a gloriously noisy thing. But it’s not something you’d aim for with modern sensibilities or worldwide acceptance in mind.

Continental’s IO-520: Big, slow turning.

By gearing the 900-series engines, Rotax allowed them to make more power than their displacement suggests but also to turn their propellers more slowly, which is good for noise and, to some extent, aerodynamics. The downside is weight and complexity, but the relative simplicity of the 900-series engines and their small size more than makes up for it. More advantages to the 900-series designs include modern combustion chambers—especially compared to the ancient chambers found in parallel-valve Continental and Lycoming engines, a good reason these engines need high-octane fuel to make decent power—and liquid cooling. In short, you can run a modern design harder—more compression ratio, more turbo boost—before destructive detonation begins to impact power and the liquid cooling further adds to the detonation margin.

So, What Should Rotax Build?

Let’s get back to the assumption that Rotax needs to build an engine in the 200-220 hp range. (I’ll set aside for now the need for a 300-hp-class engine but not completely ignore it.) I believe the 900 series as we know it has reached its limits. Consider this: The 912 iS makes 100 hp without a turbo on just under 83 cubic inches, which is 1.2 hp per cubic inch—itself more than double the power density of a Lycoming. It needs to make 91 pound-feet of torque at 5800 rpm to do so, and that requires a BMEP (brake mean effective pressure) in the combustion chamber of 165 psi to get there. While the horsepower-per-displacement number seems impressive, that’s actually a modest BMEP, or about what a 180-hp Lycoming runs. Clearly the 912 iS isn’t working all that hard.

Everyone’s fave: The 100-hp Rotax 912 iS.

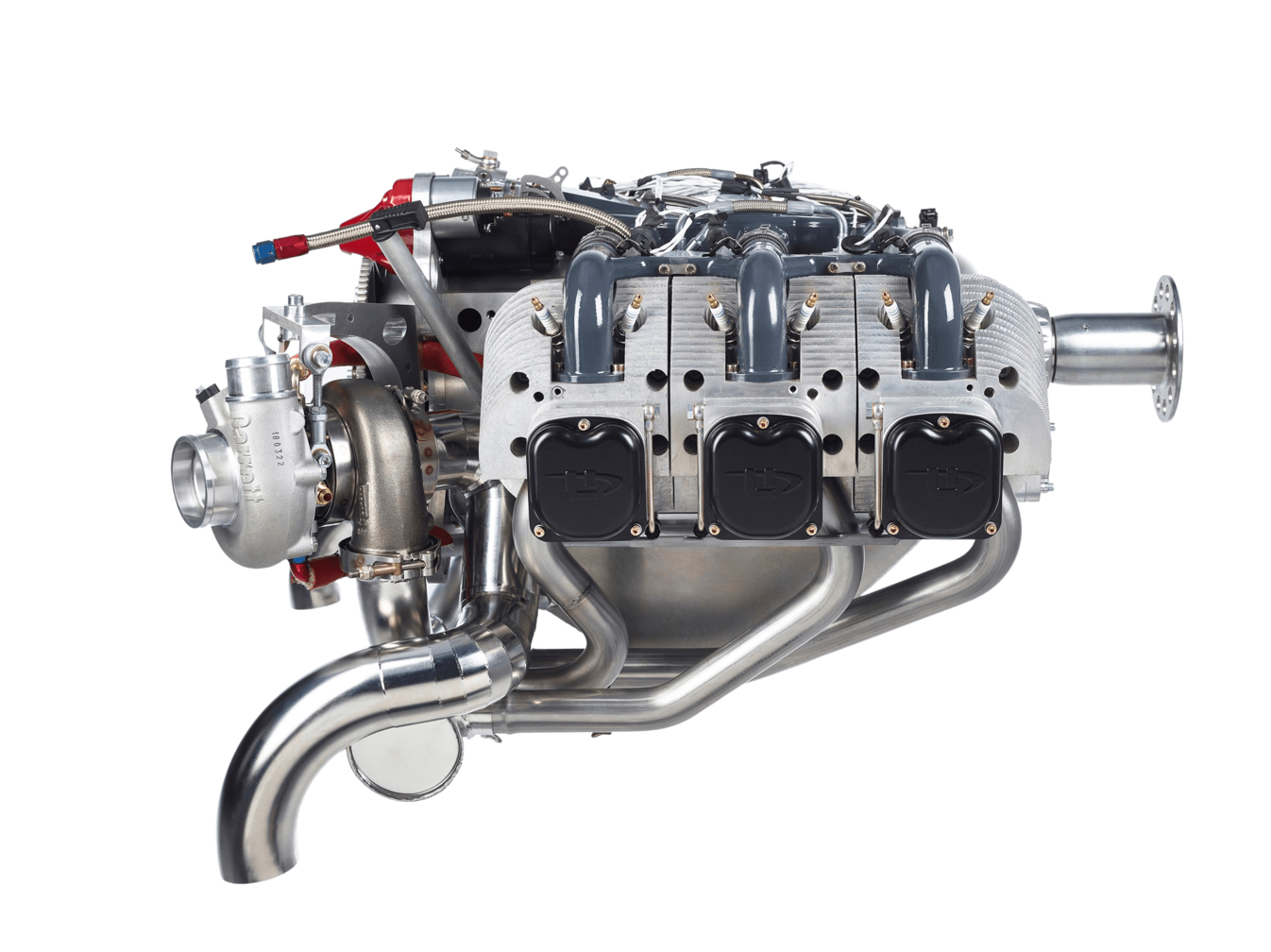

But the 916 is. With 160 hp on tap for takeoff (limited to 5 minutes, then it’s 137 continuous), it’s working really hard. First of all, power-per-cube is a really impressive 1.93 hp/cubic inch. For that power, the engine has to make 145 foot-pounds of torque at 5800 rpm, a big jump from the 912’s figures, and that requires a BMEP of 263 psi. That is a huge number, one that really stresses the engine’s ability to resist detonation, which it surely only does through strict electronic control. If you’re old enough to remember the Cosworth DFV Formula 1 engine, you may be surprised to know it made its 500-ish-hp on a BMEP of just 230 psi. Oh, how our heroes have fallen. (And, yes, I know the DFV was not turbocharged…)

Where do we go from here if the current 916 is right on the hairy edge of power production from its displacement? Well, you make it bigger. We’ve all seen the April Fool’s photos of the 912 Photoshopped into a six-cylinder but I personally think Rotax will go with a bigger four. Why? Parts count, mainly. Yes, there are good reasons to have six smaller instead of four larger cylinders, mainly for smoothness. But the manufacturing cost difference in cylinder assemblies of different dimensions is virtually zero. So the fact that the six-banger has one-third more of them only adds to weight and cost. (Though it should be said that if you’re thinking of retrofitting aircraft originally designed for Lycoming engines, weight isn’t quite the enemy you think it is.)

The Lockwood 915-powered RV-9A required a long nose for weight and balance.

No, I think it’s going to be a bigger four. And knowing that Rotax is a naturally conservative company, I’m thinking incremental from the 900 series. Back-of-the-napkin thinking has a four-cylinder flat engine with a 4.0-inch bore and 2.85-inch stroke. Why? Because this is close to the bore/stroke ratio Rotax uses in the 912 and because the shorter stroke allows the engine to continue to be geared. And if you take the average piston speed seen in the 900-series and apply that to our hypothetical 143 cubic inch engine, you’d have to limit max rpm to 5200.

I’m already way out on the limb so I might as well continue. This hypothetical engine could make 180 hp naturally aspirated on a bit more BMEP than the 912 iS musters. But turbocharged, 220 hp seems easily achievable and even, if you ran this engine as hard as Rotax does the 916, it could theoretically make 250 hp running the same BMEP of 263 psi.

Of course, not everything scales the same way. There’s more internal friction in a larger engine even if the average piston speed is the same—you have more ring area to drag around. And there are countless other interactions that people who do this for a living know about, can predict with the help of a computer and eventually discover when they actually build and test prototypes.

It’s worth noting that Rotax is not the only player in this space. The ULPower 520T engine is impressive in its own right. It’s a 321 cubic inch six-cylinder engine with, like the Rotax, two pushrod-operated valves per cylinder. (Truly, until you decide you need high revs, a two-valve head is plenty; until then, you’re just adding weight and complexity.) The 520T uses a modest amount of boost, just 38 inches for takeoff, and makes 220 hp at 2700 rpm. To do so, it’s making a phenomenal 428 pound-feet of torque from an almost-square bore/stroke ratio of 1.056:1. Heck, even a Lycoming is more “over square” than that, with a bore/stroke ratio of 1.717:1.

The ULPower’s BMEP is a modest 201 psi, above the naturally aspirated Rotax 912’s but well short of the turbo Rotaxes. I think in part this has to do with the ULPower being air cooled. No matter how nice the fins and effective your air-cooling scheme is, it’s really hard to beat the efficiency of liquid cooling. The offset is the weight and complexity of a cooling system, of course, but you have the opportunity to make much more power from any given displacement.

All this discussion is merely educated guessing. I’m 100% sure Rotax is working on an engine in the next horsepower class up. Maybe two classes up. And for all I know they could design the next engine with a more conventional up/down intake and exhaust system that would allow them to make both four- and six-cylinder versions with the same cylinders. I’m also fairly sure Rotax will take a careful approach. The 900 series has been around for more than three decades, carefully developed and curated in that time to double the power output. I don’t see a 400-hp, fire-breathing, flat-eight breaking cover, but I’d be mighty impressed if they did it.

What are your thoughts?

I’ve got a $100 bill that says Rotax “already” has a “somethingIs” thats at least 200+HP. All of the antiquated GA planes have missed the proverbial “boat”, in this case the plane! Seriously, who wants at 60 yrd old plane with a 6 pack and vacuum gauges.?

It’s incredible how they’ve just been sitting on their azzes and expect people ro buy their products!

This is a great article.But one important fact is left out A 0320 Lyc. Will not maintain level flight on 3 cylinders. It will take you to the scene of the crash!!!! Before we bow Before the Austerians they have no new physics their Engineers did.t have a Texas oil field as a neighbor. Their design were spin the he’ll out of it and buy a NEW and improved one at TBO I bought a early 80 hp 912 Lockwood told me many parts are now obsolete I would be better buying a new one.Rotax will always be a throw away engine.the cont0200 engine is about 80 years old now still in production.and you can buy parts and aftermarket parts at the corner drugstore.the reason these old technologies are still with is economics .a new 172 used to cost 12 thousand now it’s 400 thousand the middle class can.t affort a new airplane they patch the old ones or go down in size to two place with a cheaper engine with ALL the known problems of aviation wrapped up in a single product!!!!!! Liquid cooling.gear box.and double the RPM Rotax will hit a class ceiling when they try try to play ball in Cont.and Lyc. Stadium they will fail.

Enjoyed this article Marc.

Well everybody has hit on my thoughts. But here’s my 2 cents. I agree maybe one more with a little more hp but not as much as Marc stated. they will see how performance goes with the airplanes that are currently close to Mosaic and the Europe light sport planes. The 916 is pushing the price envelope to legacy engines and its burning 7-8 gph. So price will be important as to what they develop and possibly do next. With weight going up with Mosaic, a turbo diesel that can burn jet fuel. Then the out of this world dream would be a turbine. But the cost for a turbine would be like buying (2) 916 over time (maybe even more) and that would be both new and not a rebuild. So it would be for the people that could afford the extreme high cost and again if FAA allows turbine in Mosaic rules. Plus, as you stated the fuel efficiency of a turbine has yet to be proven. TurbAero is really working hard on one that can burn fuel efficiently.

A new 6 cylinder engine would only need new crankcase, crank and mabe new rods. Use all of the rest of the well tested parts.

Not if they planned to keep the 912/916 cylinders. They exhaust out the ends, not up or down. No place to put the center cylinders’ exhaust.

And why not a 5-cylinder engine? It should not be too difficult to balance.

a 2-cylinder 4-stroke engine of around 60 hp for single-seater aircraft is much needed

Rotax already made the engines you are referring to back in 2003, the Rotax 936. Maybe it’s time to dig them out of storage and give them a 2nd look now?

“BRP announced early in 2003 that they were developing the normally-aspirated Bombardier V220 and its corresponding turbocharged V300T version (both formerly called the Rotax 936) aircraft engines. These are four-stroke cycle, liquid-cooled V-6 engines developing 220hp and 300hp, respectively, at 6000rpm, geared to 0.333 (KP10/03, 12/03; SA7/03, 8/03). BRP-Rotax announced in late 2006 (SA1/07) that certification of the 936 was imminent, but that a corporate decision had been made that production will not follow. ”

https://www.enginehistory.org/Piston/HOAE/Rotax.html

I don’t think so. They were technically advanced engines but never quite met the desired weight spec. A scaled-up 900-series engine would be simpler and already have a big weight advantage.

I see your point but what if they cut two cylinders off so they had a V-4. Assuming the other specs hold, we now have 150hp normally aspirated and a 200hp boosted engine that weighs less. Most of the R&D was done 20 years ago. Seems it would cost millions less to bring to market than a fully clean-spec, upscaled 912.

Yep, they could do that. I remember seeing that engine in person about that time and it struck me as being very complex. I’m still convinced that you really don’t need DOHC or four valves per cylinder at the revs likely to be needed, so that’s just added weight and complexity. Plus electronic engine controls have come a long way in two decades. They had good reason to abandon the project back then, and I really don’t get the sense they’d be happy to dust off old engines. But we’ll see.

Where does DeltaHawk fit in this discussion?

The DeltaHawk has promise but it’s in a weight category above even the legacy air-cooled engines. It’s a bit like the 900-series engine situation in reverse. For aircraft designed around, say, four-cylinder Lycomings, the Rotax is too light and the DeltaHawk is too heavy. For aircraft designed around the Rotaxes, they’re just right, and the same would be true for the DeltaHawk. In a really interesting forum a couple of years ago at AirVenture, the presenter noted that very early turbine aircraft were based on piston airframes and were, as a result, seriously compromised. It wasn’t until the airframes were designed for turbines that they made sense.

IMHO, with MOSAIC turbine engine approval coming, less expensive 150hp++ turbine engines with all their obvious advantages will quickly replace all these ancient tech dinosaurs.

-TBoone

They might as soon as a truly viable small turbine exists that has competitive fuel specifics.

Here’s one:

https://www.heronengines.com/

Why not look into modifying the already proven Cosworth with a 500 HP water cooled engine.

I remember about 15 years ago there was a very simple little bullet proof dependable sprint car 4 cylinder 500 HP that was beating all the V8 engines at the time. When I say bullet proof it was build really beefed up huge head to block bolts . I wish I remembered what the MFG name was , not Cosworth.

What about the “D” motor as now N/A it makes 130, fully water cooled and very conservative in its RPM and power output. There are others that may be on the horizon, maybe not.

Edge has tested the 912 to 202 HP and have a 917Ti that does 180/160 with two boost profiles. It seems clear the limit is near but that 200 ponies is possible at max stress on the 912. I think a larger 4 makes more sense than a 6 cyl for all the reasons listed. Why reengineer the design entirely when you can scale and only design a few parts? The question is going to be, how do Dinosaur air cooled engine companies stay in the game?