Editor’s Note: This story originally appeared in KITPLANES magazine but since so much of the LSA world depends on Rotax engines, we thought this was worth a read here. Thirteen years into my two-year SeaRey build, OspRey finally had its engine mounted. But when I signed on the dotted line for my new Rotax 914, and with little more knowledge than how to change the oil in my car, I was nervous about my abilities to maintain this expensive engine. Because of this, back in 2014, I attended a weeklong service and maintenance class at Canadian Rotax distributor Rotech Motor, Ltd. Thanks to an excellent hands-on instructor, who acted like he had all the time in the world and a bagful of instructor tricks to teach us, by the second afternoon I had dropped my skepticism and distrust of the price/power ratio of the Rotax engine and was (almost) ready to go out and get a Rotax tattoo.

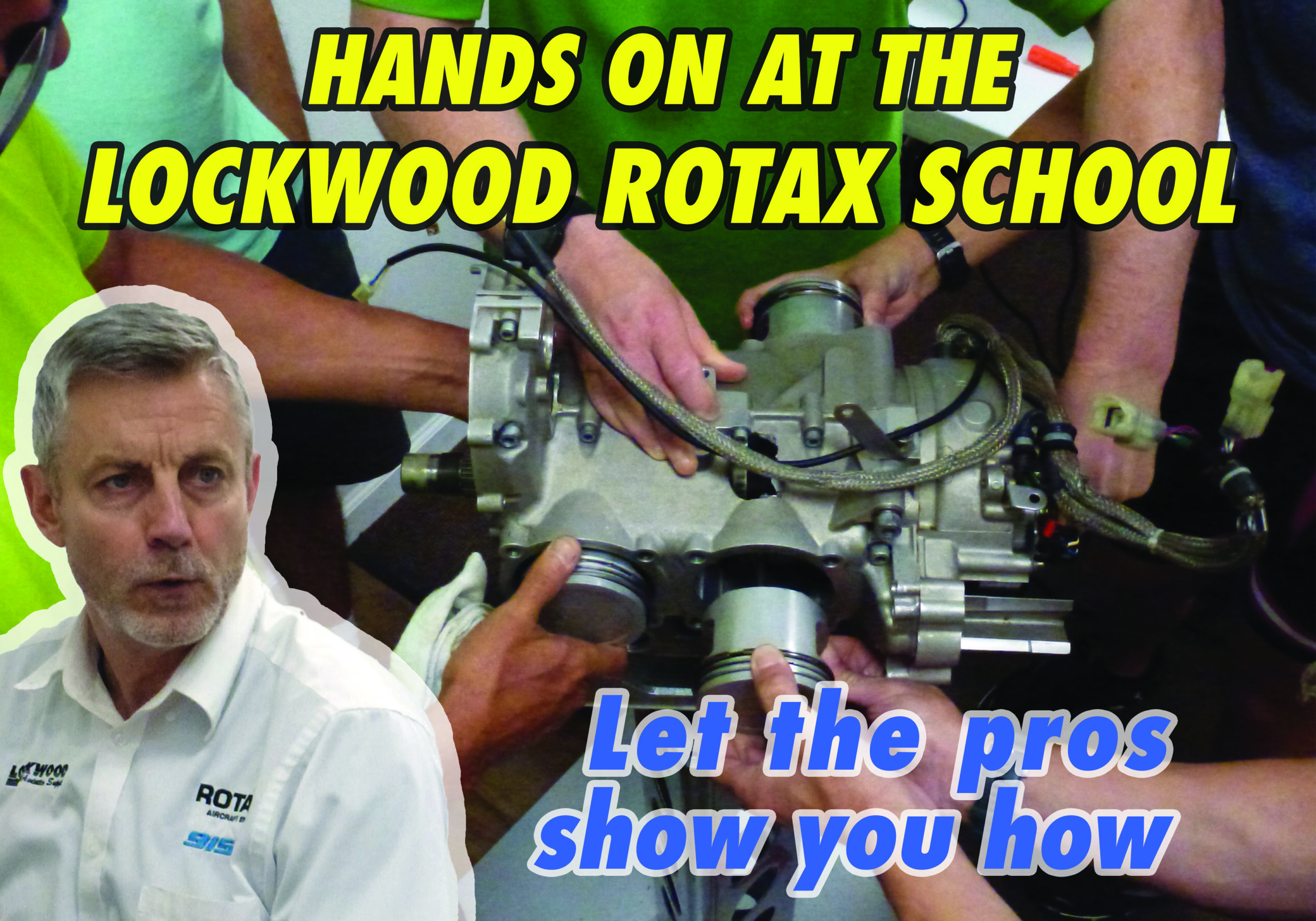

As the class went on we quickly got into the guts of the engine. No, you don’t need to bring safety glasses or rubber gloves to keep your hands clean, and Dean was generous with passing around parts to examine and using them to illustrate the system he was talking about, telling the story behind a broken connecting rod or dented piston and how to avoid it happening. Training is also done on a “penguin,” a flightless aircraft that had been damaged in a mishap. The engine mounted to it was also non-flyable, making it a perfect training tool for mechanics to practice on an engine that can run, but will not put lives at risk if someone makes a mistake.

One thing that made me nervous about the Rotax is “balancing” the dual carbs. The Rotax engine has sometimes been called two engines connected by a common crankshaft, and that’s one way to look at it. Each side of the engine has its own Bing carburetor. They must be “synced” or “balanced” so they run at the same rpm and manifold pressure at a given throttle setting. Making this happen was probably one of the biggest horror stories I’d been told about the engine, and Dean made sure that we knew he was going to go over the procedure backward and forward until we had it down.

The need to balance carbs is different than what we’re used to in legacy aircraft engines, but it’s one of the many differences that make the engine more efficient. The Bing carburetor has no separate mixture control; instead, in an elegantly simple design it automatically balances the fuel/air mixture as the airplane climbs or descends. Once the operation of the Bing carburetor is understood, you just shake your head at it and go neat!

The carb sync procedure alone was worth the cost of the course, and as Dean promised we went over it until we all felt comfortable with the procedure. The technique he teaches is proprietary so I won’t be able to explain it here, but I can tell you it took a lot of the anxiety away from me about the procedure. Lockwood also sells the tools to do this procedure, and mine came a few days after I got home. Lockwood also rents tools for 30 days, under the caveat “If you break it, you buy it,” reducing the outlay for mechanics to buy new tools.

Making Sparks

As the class went on we quickly got into the guts of the engine. No, you don’t need to bring safety glasses or rubber gloves to keep your hands clean, and Dean was generous with passing around parts to examine and using them to illustrate the system he was talking about, telling the story behind a broken connecting rod or dented piston and how to avoid it happening. Training is also done on a “penguin,” a flightless aircraft that had been damaged in a mishap. The engine mounted to it was also non-flyable, making it a perfect training tool for mechanics to practice on an engine that can run, but will not put lives at risk if someone makes a mistake.

One thing that made me nervous about the Rotax is “balancing” the dual carbs. The Rotax engine has sometimes been called two engines connected by a common crankshaft, and that’s one way to look at it. Each side of the engine has its own Bing carburetor. They must be “synced” or “balanced” so they run at the same rpm and manifold pressure at a given throttle setting. Making this happen was probably one of the biggest horror stories I’d been told about the engine, and Dean made sure that we knew he was going to go over the procedure backward and forward until we had it down.

The need to balance carbs is different than what we’re used to in legacy aircraft engines, but it’s one of the many differences that make the engine more efficient. The Bing carburetor has no separate mixture control; instead, in an elegantly simple design it automatically balances the fuel/air mixture as the airplane climbs or descends. Once the operation of the Bing carburetor is understood, you just shake your head at it and go neat!

The carb sync procedure alone was worth the cost of the course, and as Dean promised we went over it until we all felt comfortable with the procedure. The technique he teaches is proprietary so I won’t be able to explain it here, but I can tell you it took a lot of the anxiety away from me about the procedure. Lockwood also sells the tools to do this procedure, and mine came a few days after I got home. Lockwood also rents tools for 30 days, under the caveat “If you break it, you buy it,” reducing the outlay for mechanics to buy new tools.

Making Sparks

The class is standardized around the world, so you can rest assured that you won’t miss anything by taking a class at another location closer than Lockwood. I found that taking classes from two separate schools complemented my knowledge, with each instructor and location having their own separate style and training aids. In my case, having bought the engine from Lockwood added to the reasons to take a trip to Florida.

Of course, having bought my engine from Lockwood and being a cheap pilot, I did ask if there was a discount. It’s easy to multiply X number of students by the tuition of the class and think Lockwood is making money hand over fist for a seemingly few days of Dean talking. But remember: You’re not paying for the class; you’re paying for the decades of experience Dean and the Lockwood crew have accumulated and are passing on to you. More than once Dean called me out with SeaRey-specific maintenance or installation instructions, and by the end of the course I lost track of how many potential hours of frustration and thousands of dollars in mistakes Dean saved me.

Note that this is not a “gentlemen’s course” where Dean will stomp his foot for something that will be on the open-book, take-home exam. However, he was also willing to help with the more obscure topics, telling us to wait to answer some questions if we can’t find the answer, and we’d probably hear it from his lecture before the exam. The class is not airline ground school intense, but it did remind me of what a friend of mine says about formation flying: It’s not work, but it is very, very hard play.

There’s an old saying that you get what you pay for. Airplanes are an investment of time and money, and the knowledge you get from this class will save you both in the long run. At a minimum, I think any Rotax builder/operator needs to take the service class and, if possible, hang out and do the maintenance one as well.

Oh, how did I do on the test? Well, let’s just say I passed, but I won’t be hanging out a shingle to do work on Rotaxes. What I have, though, is a license to learn.

The class is standardized around the world, so you can rest assured that you won’t miss anything by taking a class at another location closer than Lockwood. I found that taking classes from two separate schools complemented my knowledge, with each instructor and location having their own separate style and training aids. In my case, having bought the engine from Lockwood added to the reasons to take a trip to Florida.

Of course, having bought my engine from Lockwood and being a cheap pilot, I did ask if there was a discount. It’s easy to multiply X number of students by the tuition of the class and think Lockwood is making money hand over fist for a seemingly few days of Dean talking. But remember: You’re not paying for the class; you’re paying for the decades of experience Dean and the Lockwood crew have accumulated and are passing on to you. More than once Dean called me out with SeaRey-specific maintenance or installation instructions, and by the end of the course I lost track of how many potential hours of frustration and thousands of dollars in mistakes Dean saved me.

Note that this is not a “gentlemen’s course” where Dean will stomp his foot for something that will be on the open-book, take-home exam. However, he was also willing to help with the more obscure topics, telling us to wait to answer some questions if we can’t find the answer, and we’d probably hear it from his lecture before the exam. The class is not airline ground school intense, but it did remind me of what a friend of mine says about formation flying: It’s not work, but it is very, very hard play.

There’s an old saying that you get what you pay for. Airplanes are an investment of time and money, and the knowledge you get from this class will save you both in the long run. At a minimum, I think any Rotax builder/operator needs to take the service class and, if possible, hang out and do the maintenance one as well.

Oh, how did I do on the test? Well, let’s just say I passed, but I won’t be hanging out a shingle to do work on Rotaxes. What I have, though, is a license to learn.